Select your language

Factory Tour

„Take a look at our production facility in Oberdischingen and discover the precision with which our hardness testers are manufactured. “

- Barofix III laser-controlled positioning device with optical and automatic centering for plane-parallel plates / O-rings

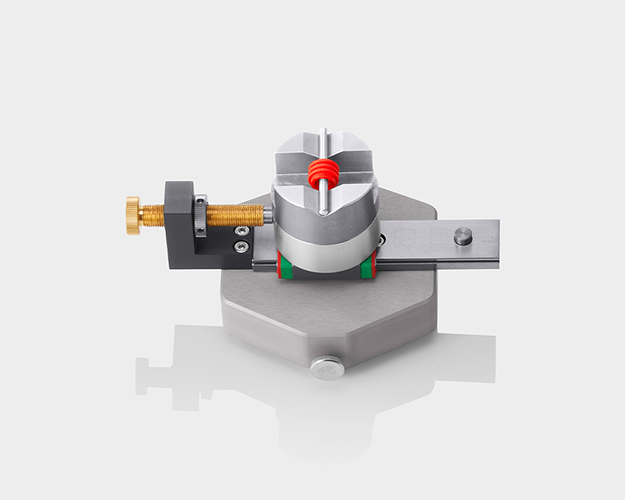

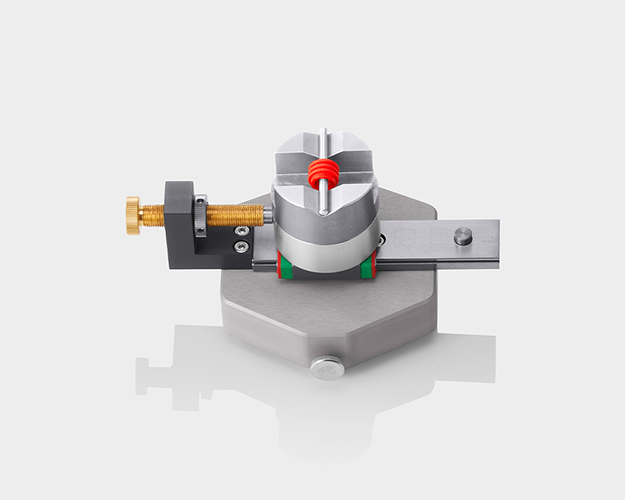

- Barofix quick centering device with downholder device and support plate for O-rings

- Centrofix quick centering devices for hoses

- DAkkS calibration certificate for Measuring device

- Reference elastomer blocks with DAkkS calibration certificate

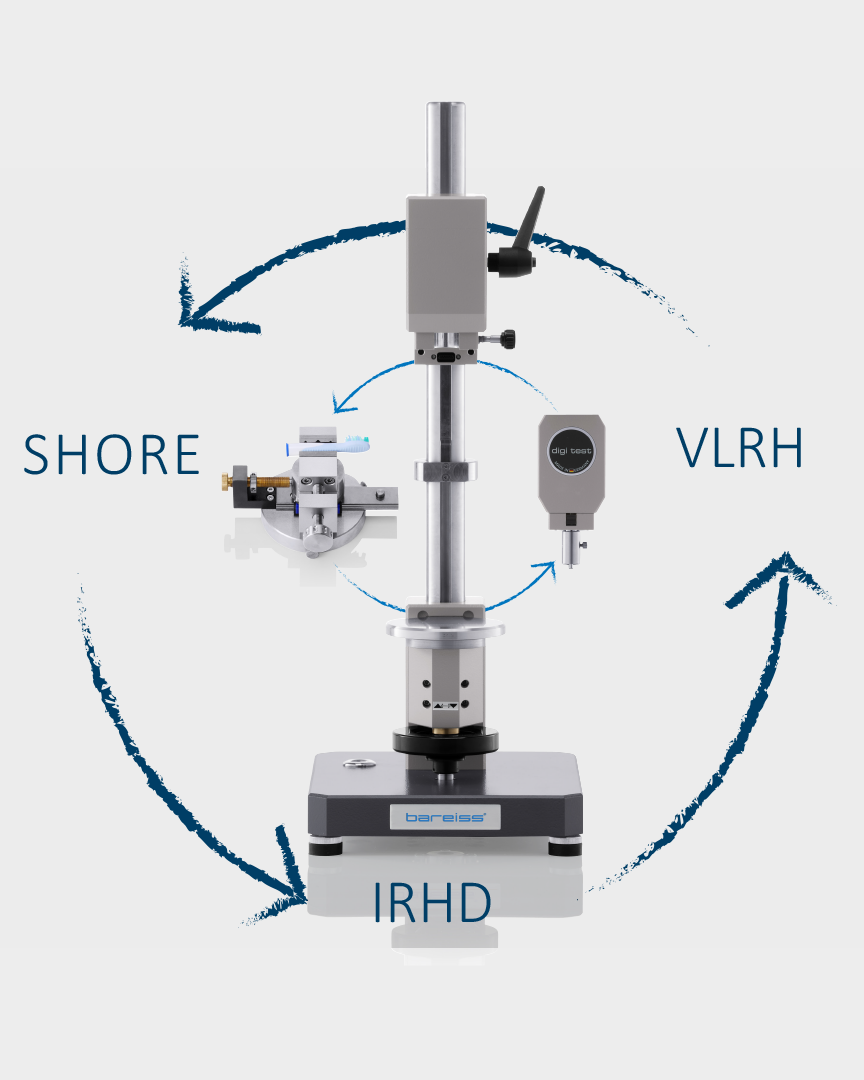

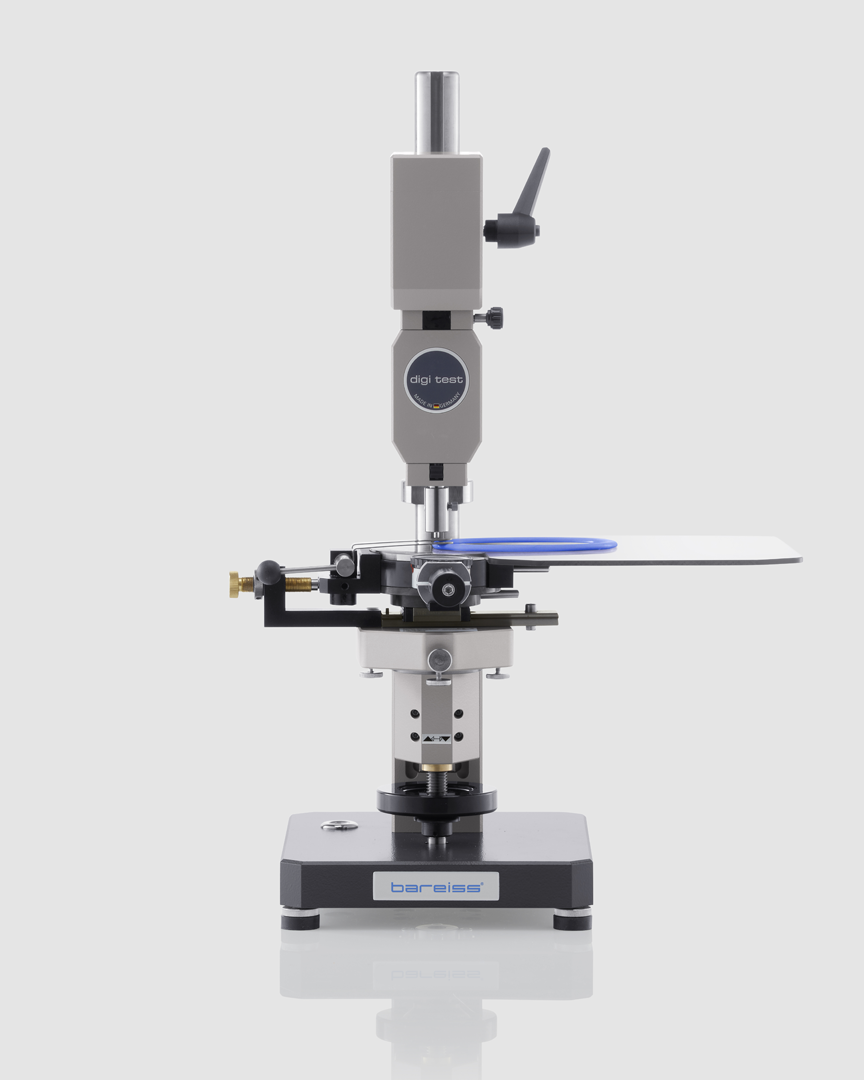

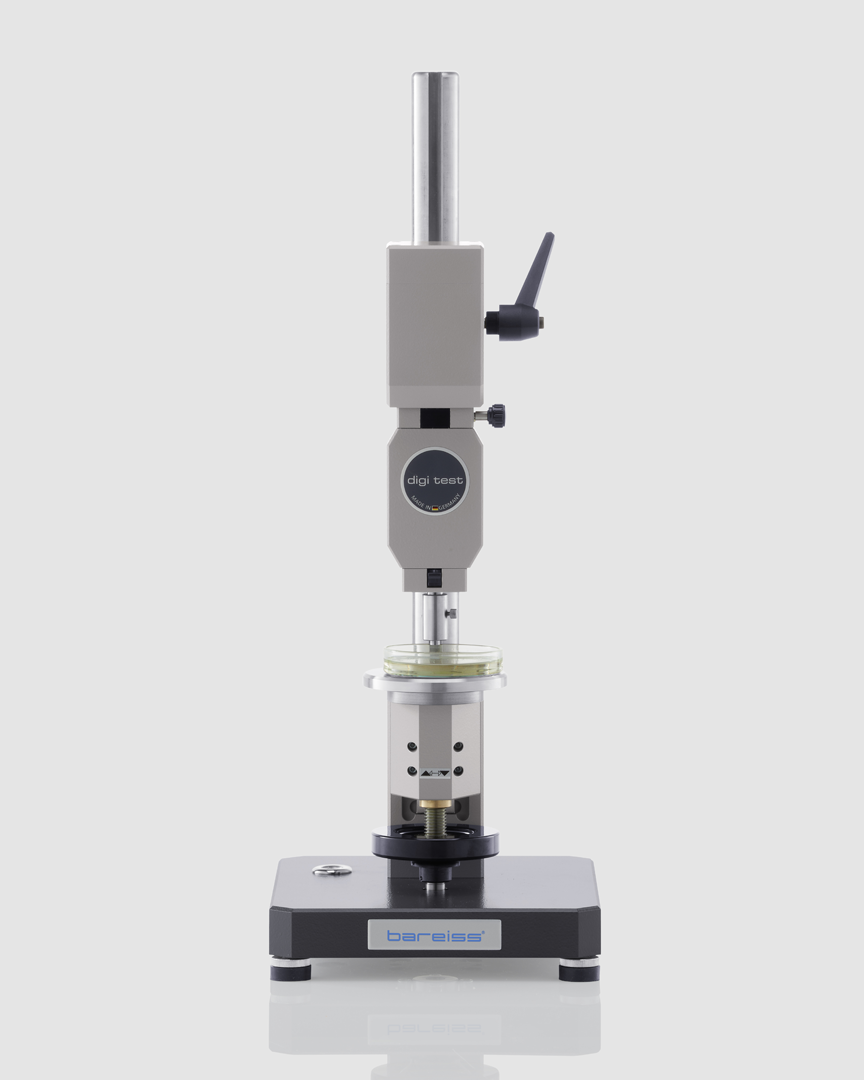

„The modular digi test II guarantees you maximum flexibility for the hardness testing on elastomers, polymers and flexible cellular materials. With just a few steps and without additional tools, you can replace the available measuring devices with indenters according to Shore, VLRH or IRHD. This process allows for a quick switch between different measuring methods.“

- Software measurement data acquisition and analysis system

- Magnifying glass with 2.5x magnification, flexible, swiveling

- Measuring devices for Shore, IRHD and VLRH

- „For more information, use our download service.“

- data sheet

- areas of application

- Measuring method

- Shore A

- Shore A0

- Shore D

- Shore 0

- Shore 00

- Shore 000

- Shore 000S

- Shore E

- Shore B

- Shore C

- Shore D0

- Micro Shore A

- Micro Shore D

- Shore AM

- Shore M

- IRHD L

- IRHD N

- IRHD M

- IRHD H

- VLRH

- Standards

- ASTM D1415

- ASTM D2240

- DIN ISO 48-2

- DIN ISO 48-3

- DIN ISO 48-4

- DIN EN ISO 868

- TD 00002001

- TD 00002002

- NFT 46-003

- Sample geometry

O-rings

Sheet material

Workpieces and thin samples- Resolution

0.1

- Areas of application

The digi test II accessories allow for a reliable hardness testing process on concave, convex and uneven surfaces. It is also possible to perform a hardness test with a material thickness of less than 6 mm, which means it is also suitable for samples of very small sizes.

- Technical Specifications

Power supply: 100-240VAC; 50/60Hz

Protection type: IP 20

Measurements: Test stand: 200 x 250 x 570 mm

Electronic unit: 260 x 260 x 11 mm

Weight: Test stand: 14.0 kg

Electronic unit: 2.5 kg- Interface

USB and RS 232 interfaces for data transfer

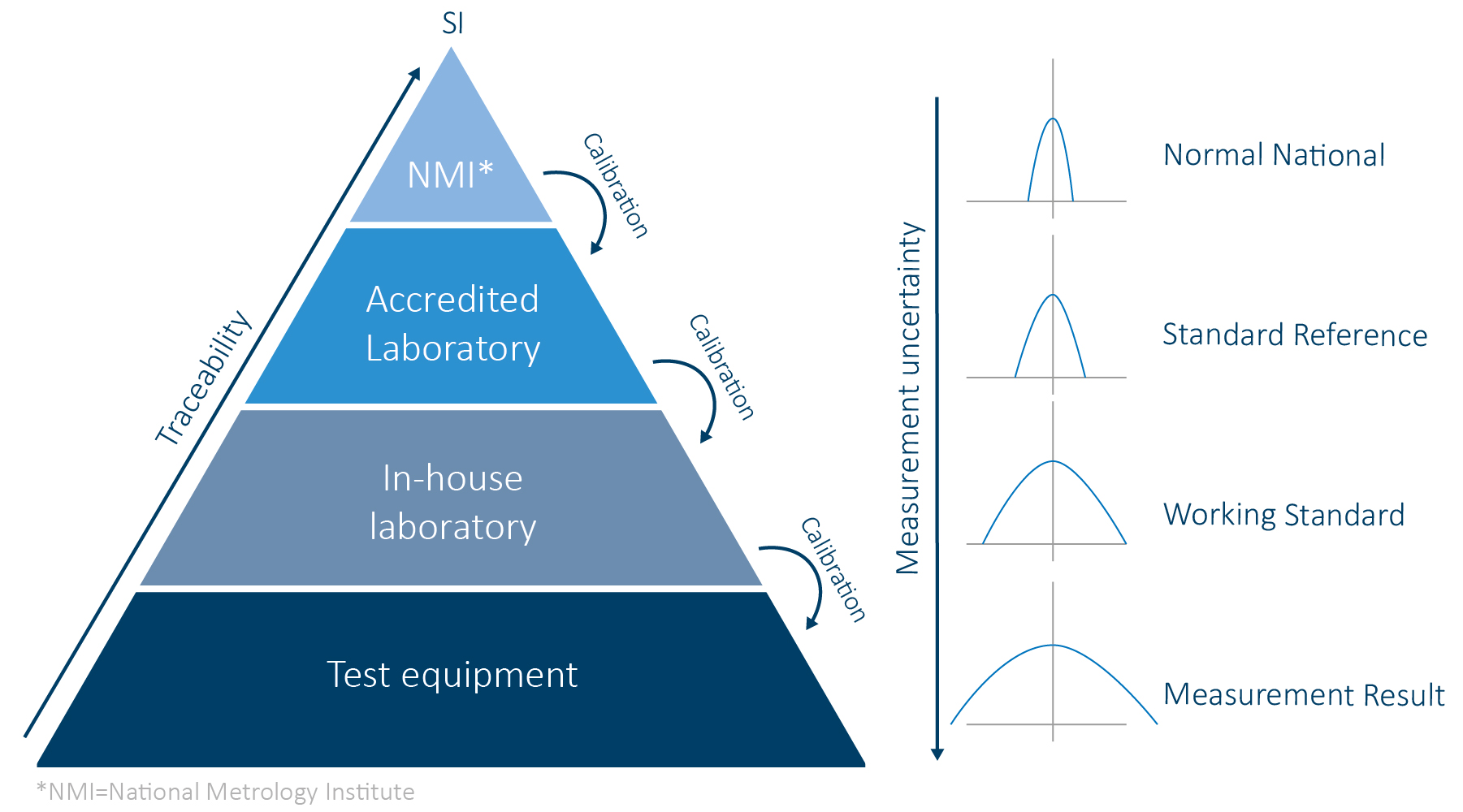

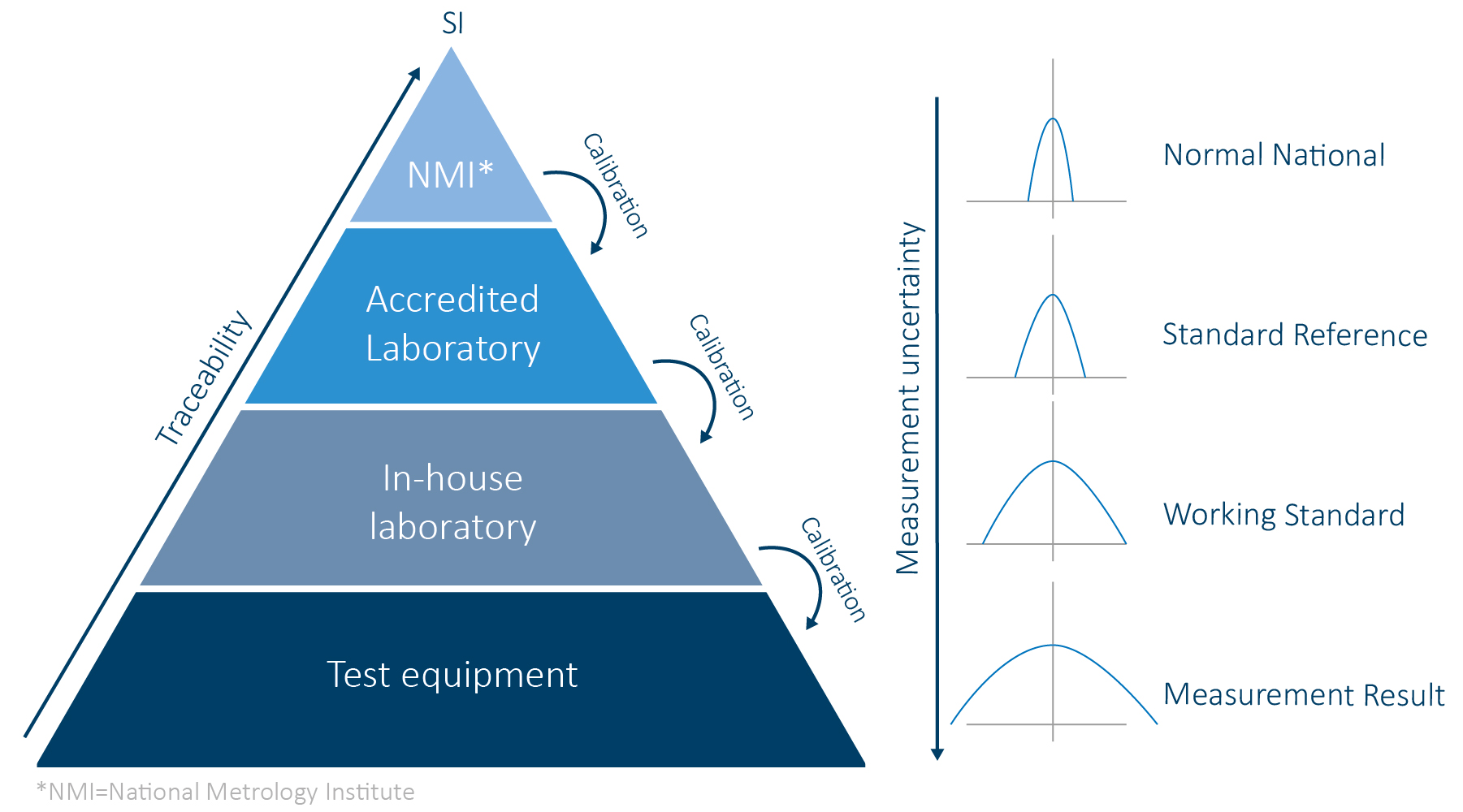

- Traceability

NMI = National Metrological Institute

Metrological traceability (VIM 2.41): Property of a measurement result, whereby the result can be traced back to a reference, through a documented, uninterrupted chain of calibrations, each of which contributing to the measurement uncertainty.

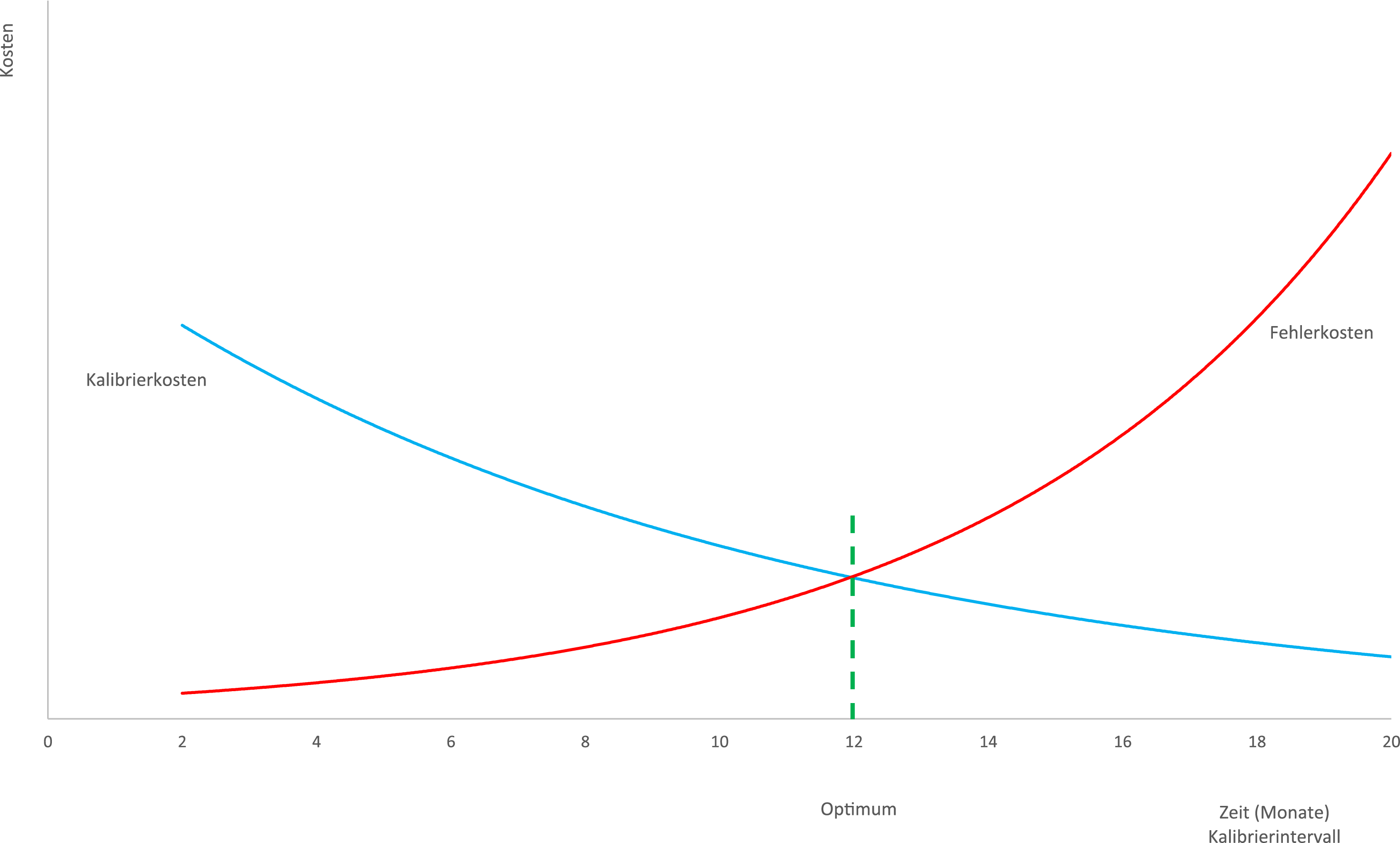

- Calibration reminder

In accordance with the calibration rhythm you have set, you will receive an automatic reminder that your hardness tester has to be calibrated soon, as a special service from our company. With the purchase of a new device, this reminder is initially sent annually, but it can be set at a specific interval you desire. You will usually receive the reminder approximately one month before the due date.

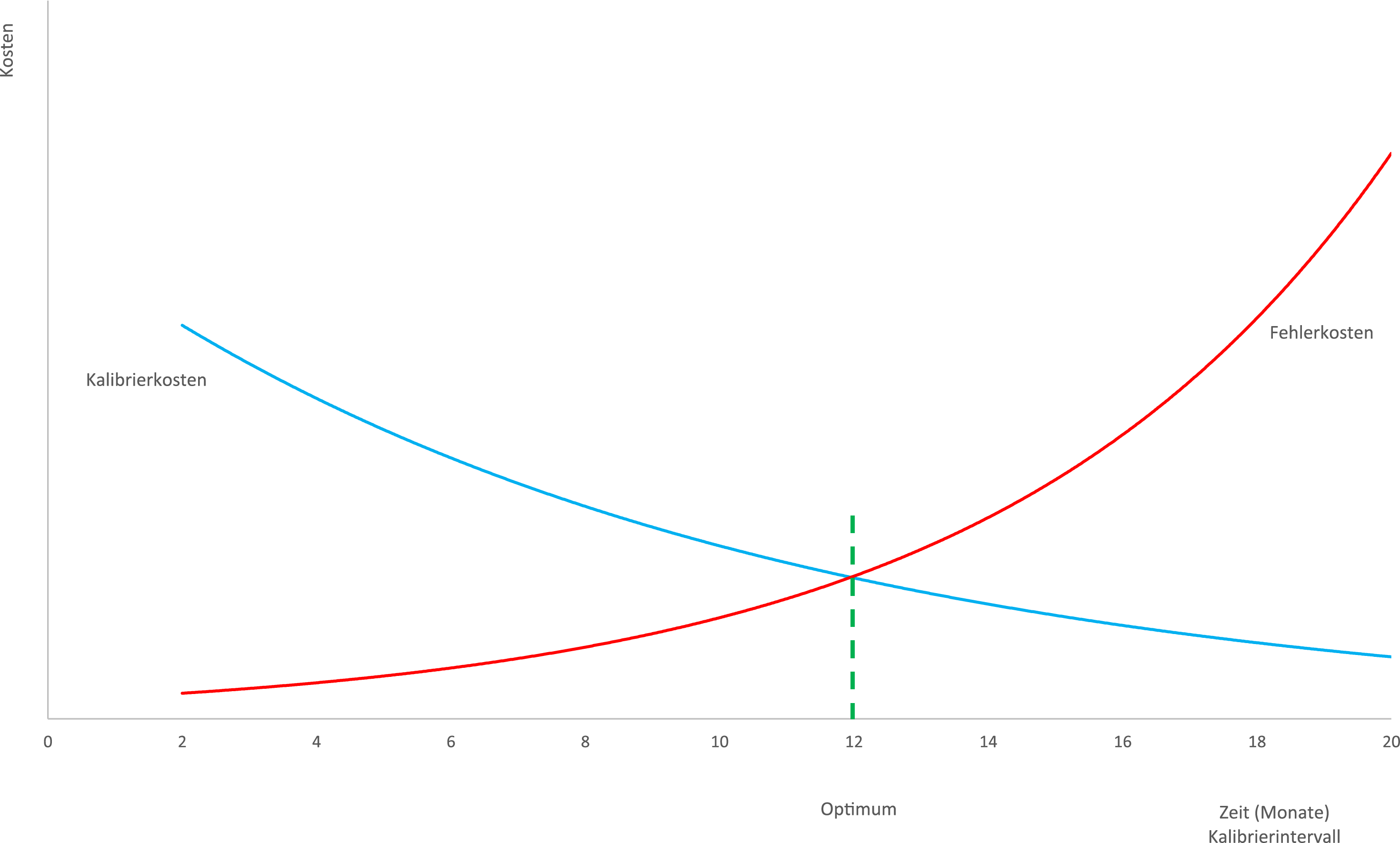

When it comes to determining the calibration rhythm, an optimum should be found between the calibration costs and the error costs.

- Service

We are happy to answer any questions you might have about hardness testing!

Telephone +49 7305 9642-0

Fax +49 7305 9642-22

EmailThis email address is being protected from spambots. You need JavaScript enabled to view it. Opening hours:

Monday – Thursday: 07.00 a.m. - 16.00 p.m.

Friday: 07.00 a.m. - 12.00 p.m.- digi test II

Modular digital measuring device for fully-automated hardness tests, according to Shore, VLRH and IRHD on polymers with variable test geometries.

- normal

- Shore A

- Shore A0

- Shore D

- Shore 0

- Shore 00

- Shore 000

- Shore 000S

- Shore E

- Shore B

- Shore C

- Shore D0

- Micro Shore A

- Micro Shore D

- Shore AM

- Shore M

- IRHD L

- IRHD N

- IRHD M

- IRHD H

- VLRH

- ASTM D1415

- ASTM D2240

- DIN ISO 48-2

- DIN ISO 48-3

- DIN ISO 48-4

- DIN EN ISO 868

- TD 00002001

- TD 00002002

- NFT 46-003

O-rings

Sheet material

Workpieces and thin samples

0.1

The digi test II accessories allow for a reliable hardness testing process on concave, convex and uneven surfaces. It is also possible to perform a hardness test with a material thickness of less than 6 mm, which means it is also suitable for samples of very small sizes.

Power supply: 100-240VAC; 50/60Hz

Protection type: IP 20

Measurements: Test stand: 200 x 250 x 570 mm

Electronic unit: 260 x 260 x 11 mm

Weight: Test stand: 14.0 kg

Electronic unit: 2.5 kg

USB and RS 232 interfaces for data transfer

NMI = National Metrological Institute

Metrological traceability (VIM 2.41): Property of a measurement result, whereby the result can be traced back to a reference, through a documented, uninterrupted chain of calibrations, each of which contributing to the measurement uncertainty.

In accordance with the calibration rhythm you have set, you will receive an automatic reminder that your hardness tester has to be calibrated soon, as a special service from our company. With the purchase of a new device, this reminder is initially sent annually, but it can be set at a specific interval you desire. You will usually receive the reminder approximately one month before the due date.

When it comes to determining the calibration rhythm, an optimum should be found between the calibration costs and the error costs.

We are happy to answer any questions you might have about hardness testing!

Telephone +49 7305 9642-0

Fax +49 7305 9642-22

Email service@bareiss.de

Opening hours:

Monday – Thursday: 07.00 a.m. - 16.00 p.m.

Friday: 07.00 a.m. - 12.00 p.m.

„The modular digi test II guarantees you maximum flexibility for the hardness testing on elastomers, polymers and flexible cellular materials. With just a few steps and without additional tools, you can replace the available measuring devices with indenters according to Shore, VLRH or IRHD. This process allows for a quick switch between different measuring methods.“

Downloads

„For more information, use our download service.“

Factory Tour

„Take a look at our production facility in Oberdischingen and discover the precision with which our hardness testers are manufactured. “

Accessories

Request a quote