Select your language

Factory Tour

„Take a look at our production facility in Oberdischingen and discover the precision with which our hardness testers are manufactured. “

- Barofix quick centering device with downholder device and support plate for O-rings

- Magnifying glass with 2.5x magnification, flexible, pivoting

- DAkkS calibration certificate

- Centrofix quick centering devices for hoses

- Software „Hardtest“

„Our budget-friendly tester offers you the possibility to perform semi-automatic hardness tests with the methods IRHD M and IRHD N by means of interchangeable measuring devices - and all this with the same quality expected from Bareiss.“

- Embedding Material

- „For more information, use our download service.“

- data sheet

- areas of application

- Measuring method

IRHD L

IRHD N

IRHD M- Standards

- ASTM D792

- ASTM D1415

- DIN 53512

- DIN ISO 48-2

- NF ISO 48

- Sample geometry

O-rings

Sheet material

Workpieces and thin samples- Resolution

0.1 IRHD

- Areas of application

In the IRHD M application range, the IRHD Compact III is used for hardness determination of hoses, O-rings, molded parts, standard plates and gaskets with a minimum material thickness of 0.6 mm.

In the IRHD N application range, the IRHD Compact III determines the hardness of soft rubber, highly elastic materials and plastically deformable materials with a minimum material thickness of 6.0 mm.- Technical Specifications

Test stand Measurements W x D x H: 200 x 250 x 570

Test stand Weight 9,0 kg

Measuring device IRHD N Measurements W x D x H: 70 x 90 x 150

Measuring device IRHD N Weight 1,9 kg

Measuring device IRHD M Measurements W x D x H: 160 x 100 x 140

Measuring device IRHD M Weight 1,4 kg

- Interface

RS 232 interfaces for data transfer

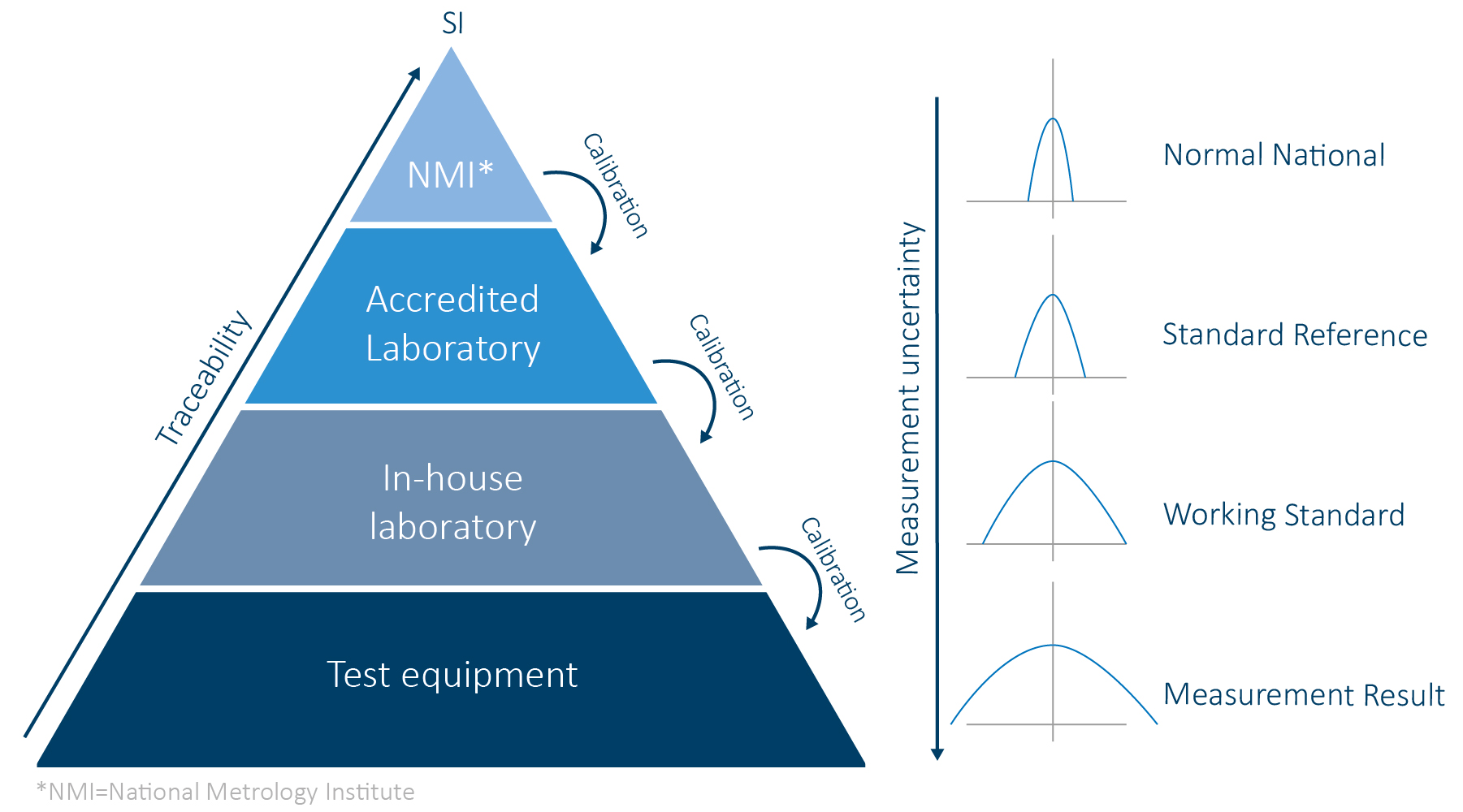

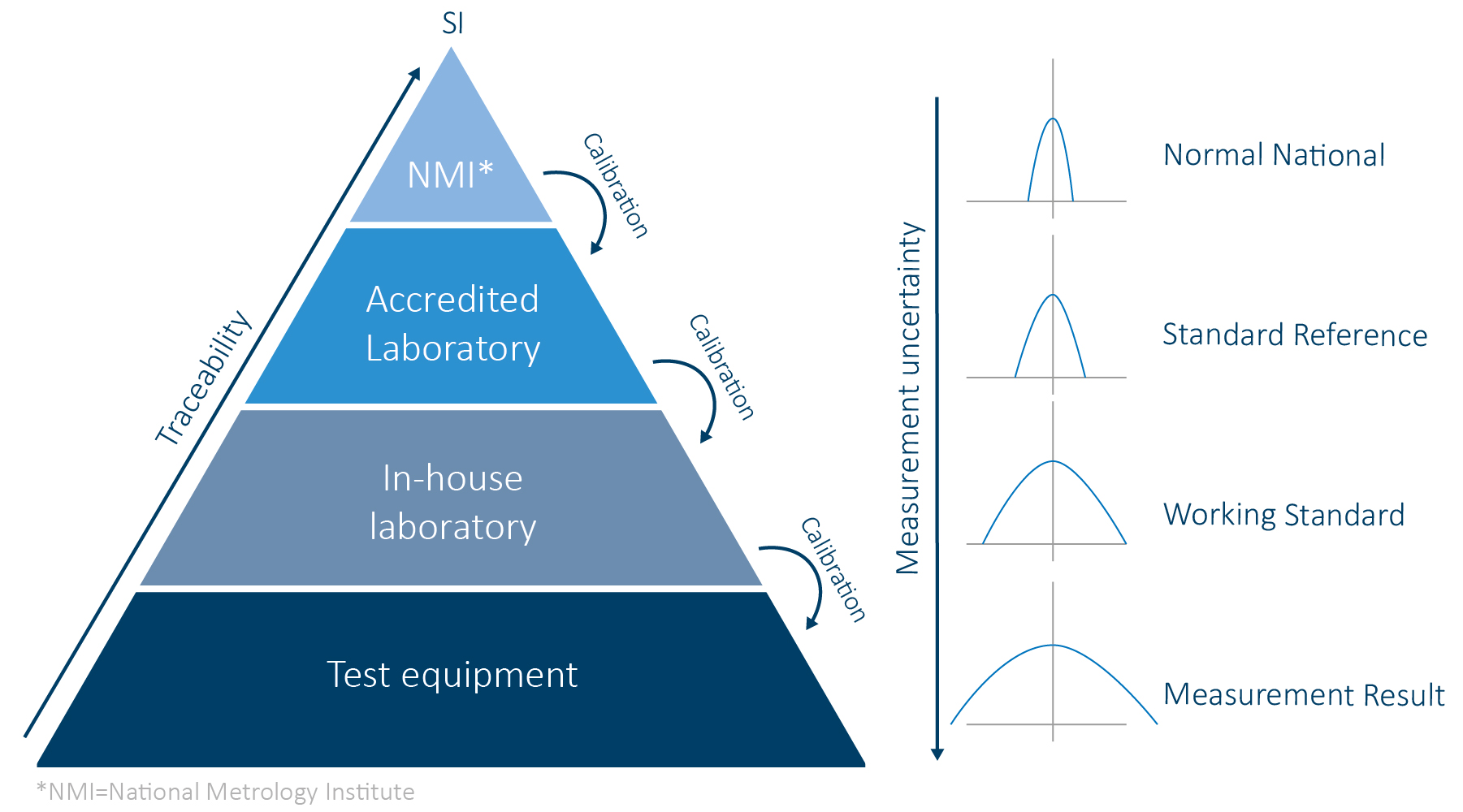

- Traceability

NMI = National Metrological Institute

Metrological traceability (VIM 2.41): Property of a measurement result, whereby the result can be traced back to a reference, through a documented, uninterrupted chain of calibrations, each of which contributing to the measurement uncertainty.- Calibration reminder

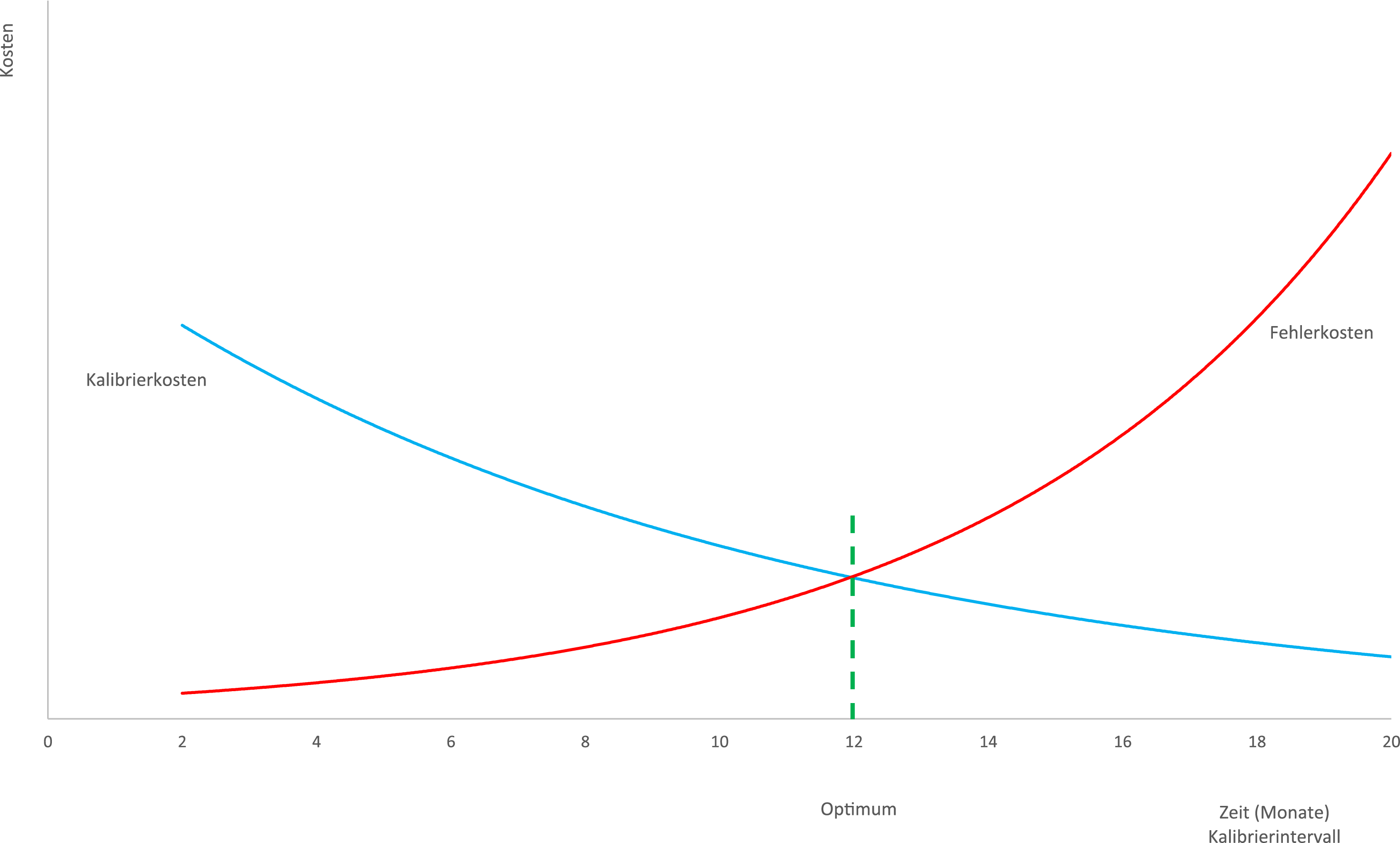

In accordance with the calibration rhythm you have set, you will receive an automatic reminder that your hardness tester has to be calibrated soon, as a special service from our company. With the purchase of a new device, this reminder is initially sent annually, but it can be set at a specific interval you desire. You will usually receive the reminder approximately one month before the due date.

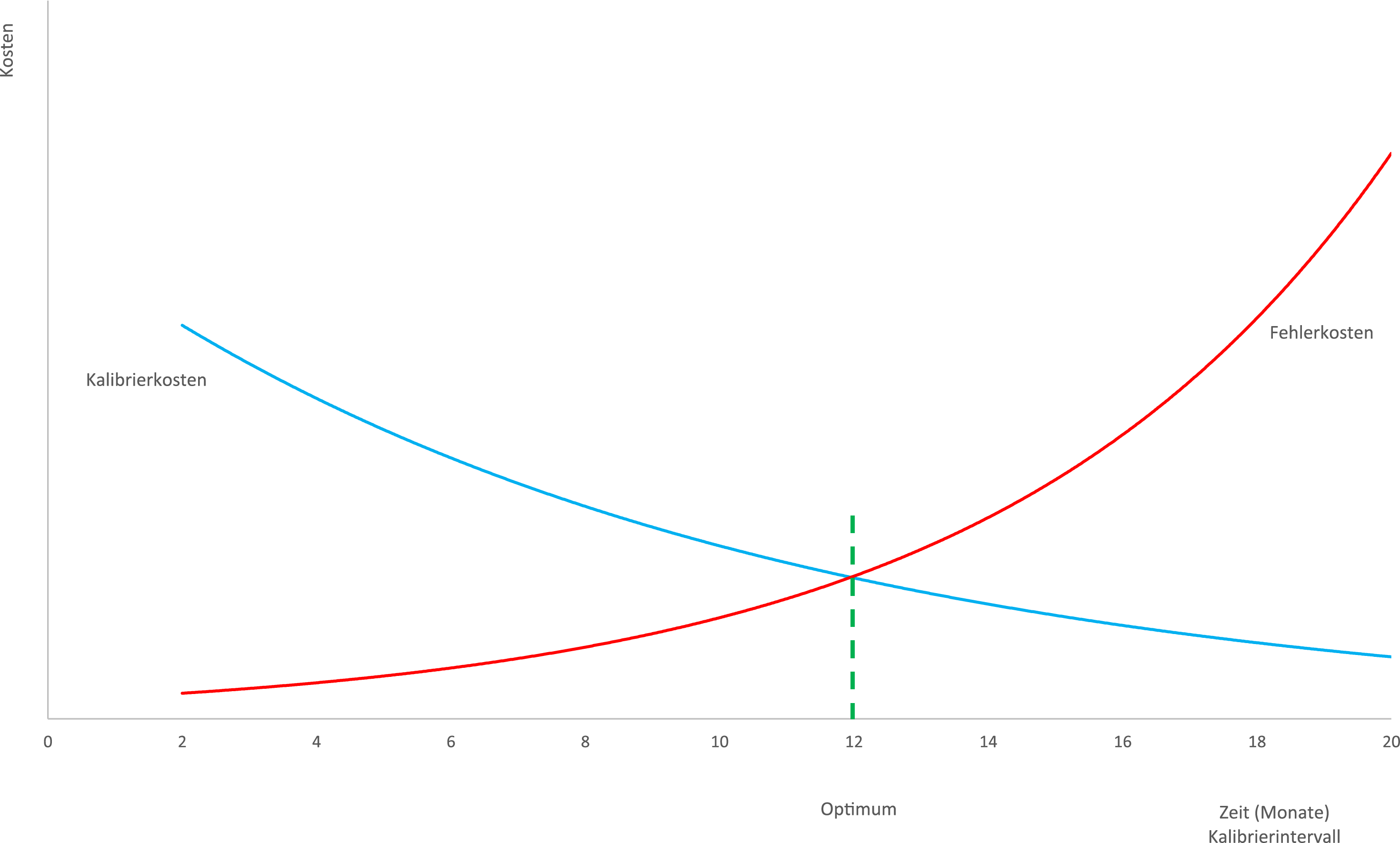

When it comes to determining the calibration rhythm, an optimum should be found between the calibration costs and the error costs.

- Service

We are happy to answer any questions you might have about hardness testing!

Telephone +49 7305 9642-0

Fax +49 7305 9642-22

EmailThis email address is being protected from spambots. You need JavaScript enabled to view it. Opening hours:

Monday – Thursday: 07.00 a.m. - 16.00 p.m.

Friday: 07.00 a.m. - 12.00 p.m.- IRHD Compact III

Innovative testing device for assured quality in rubber, plastic and all elastic materials.

- normal

IRHD L

IRHD N

IRHD M

- ASTM D792

- ASTM D1415

- DIN 53512

- DIN ISO 48-2

- NF ISO 48

O-rings

Sheet material

Workpieces and thin samples

0.1 IRHD

In the IRHD M application range, the IRHD Compact III is used for hardness determination of hoses, O-rings, molded parts, standard plates and gaskets with a minimum material thickness of 0.6 mm.

In the IRHD N application range, the IRHD Compact III determines the hardness of soft rubber, highly elastic materials and plastically deformable materials with a minimum material thickness of 6.0 mm.

Test stand Measurements W x D x H: 200 x 250 x 570

Test stand Weight 9,0 kg

Measuring device IRHD N Measurements W x D x H: 70 x 90 x 150

Measuring device IRHD N Weight 1,9 kg

Measuring device IRHD M Measurements W x D x H: 160 x 100 x 140

Measuring device IRHD M Weight 1,4 kg

RS 232 interfaces for data transfer

NMI = National Metrological Institute

Metrological traceability (VIM 2.41): Property of a measurement result, whereby the result can be traced back to a reference, through a documented, uninterrupted chain of calibrations, each of which contributing to the measurement uncertainty.

In accordance with the calibration rhythm you have set, you will receive an automatic reminder that your hardness tester has to be calibrated soon, as a special service from our company. With the purchase of a new device, this reminder is initially sent annually, but it can be set at a specific interval you desire. You will usually receive the reminder approximately one month before the due date.

When it comes to determining the calibration rhythm, an optimum should be found between the calibration costs and the error costs.

We are happy to answer any questions you might have about hardness testing!

Telephone +49 7305 9642-0

Fax +49 7305 9642-22

Email service@bareiss.de

Opening hours:

Monday – Thursday: 07.00 a.m. - 16.00 p.m.

Friday: 07.00 a.m. - 12.00 p.m.

„Our budget-friendly tester offers you the possibility to perform semi-automatic hardness tests with the methods IRHD M and IRHD N by means of interchangeable measuring devices - and all this with the same quality expected from Bareiss.“

Downloads

„For more information, use our download service.“

Factory Tour

„Take a look at our production facility in Oberdischingen and discover the precision with which our hardness testers are manufactured. “

Accessories

Request a quote