Select your language

Factory Tour

„Take a look at our production facility in Oberdischingen and discover the precision with which we manufacture our hardness testers.“

- DAkkS calibration certificate

- DGUV Inspection

„With the patented KalRock, you can verify the penetration depth measuring device of your Rockwell hardness tester. With a resolution of 0.3 µm, it controls the length measuring system of the hardness testers, under a maximum preload of 10 kg.“

- „For more information, use our download service.“

- data sheet

- areas of application

- Measuring method

Penetration depth path +/- 0,4 mm

- Standards

- DIN EN ISO 2039-1

- DIN EN ISO 6508-2

- Resolution

0.1 μm

- Areas of application

Measuring device for the calibration of the penetration depth measuring device of Rockwell hardness testing machines. Available with DAkkS calibration certificate.

- Technical Specifications

Power supply: 100 – 240 VAC; 50 / 60 Hz

Protection type: IP 30

Measurements: Electronic unit: 290 x 260 x 210 mm

Measuring device: Durchmesser 90 mm, Länge 125 mm

Weight: Electronic unit: 2,5 kg

Measuring device: 3,2 kgFine adjustment of length

Measuring device: ± 0,4 mmDisplay accuracy

Measuring device: ± 0,2 μm- Interface

RS-232 und USB Interface

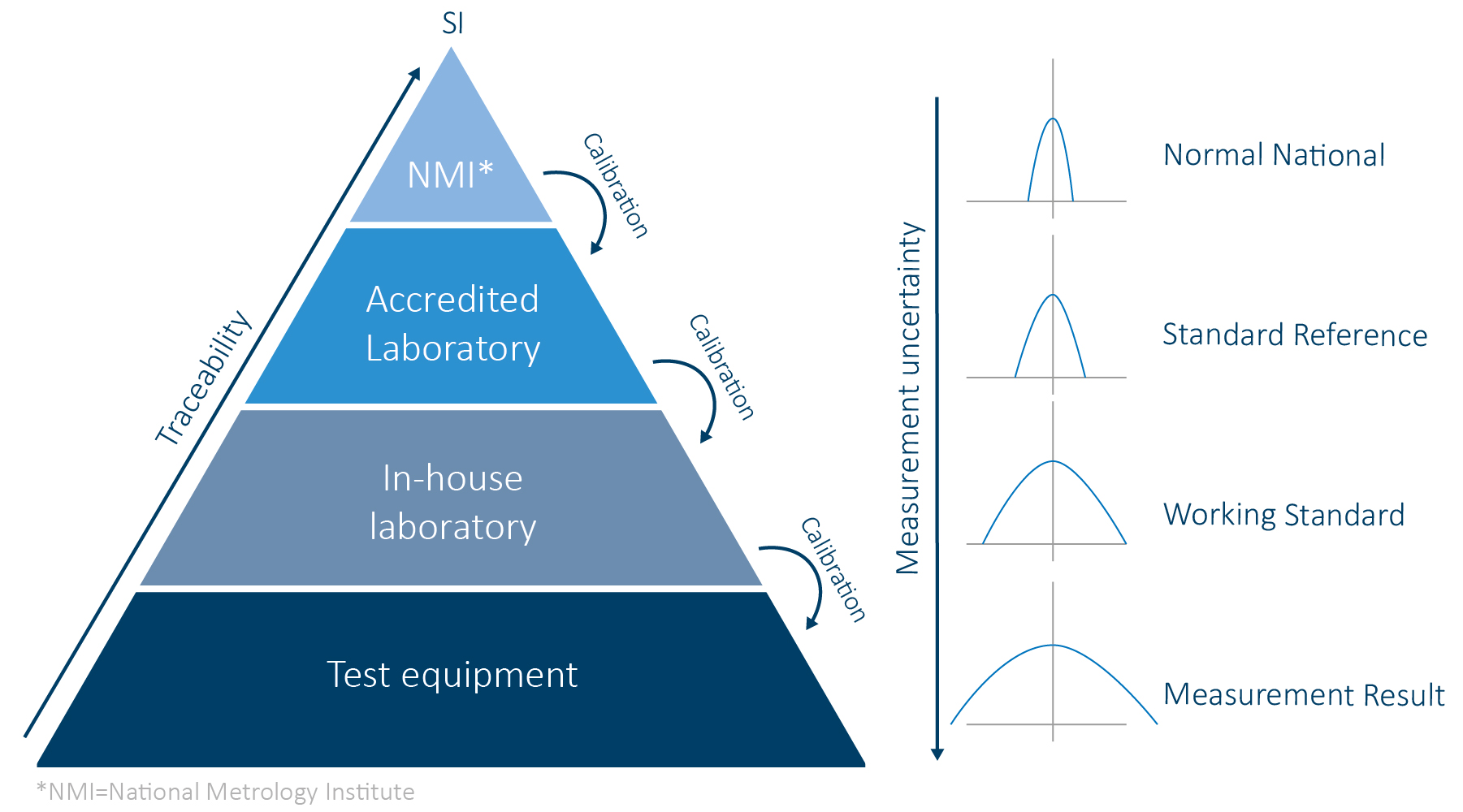

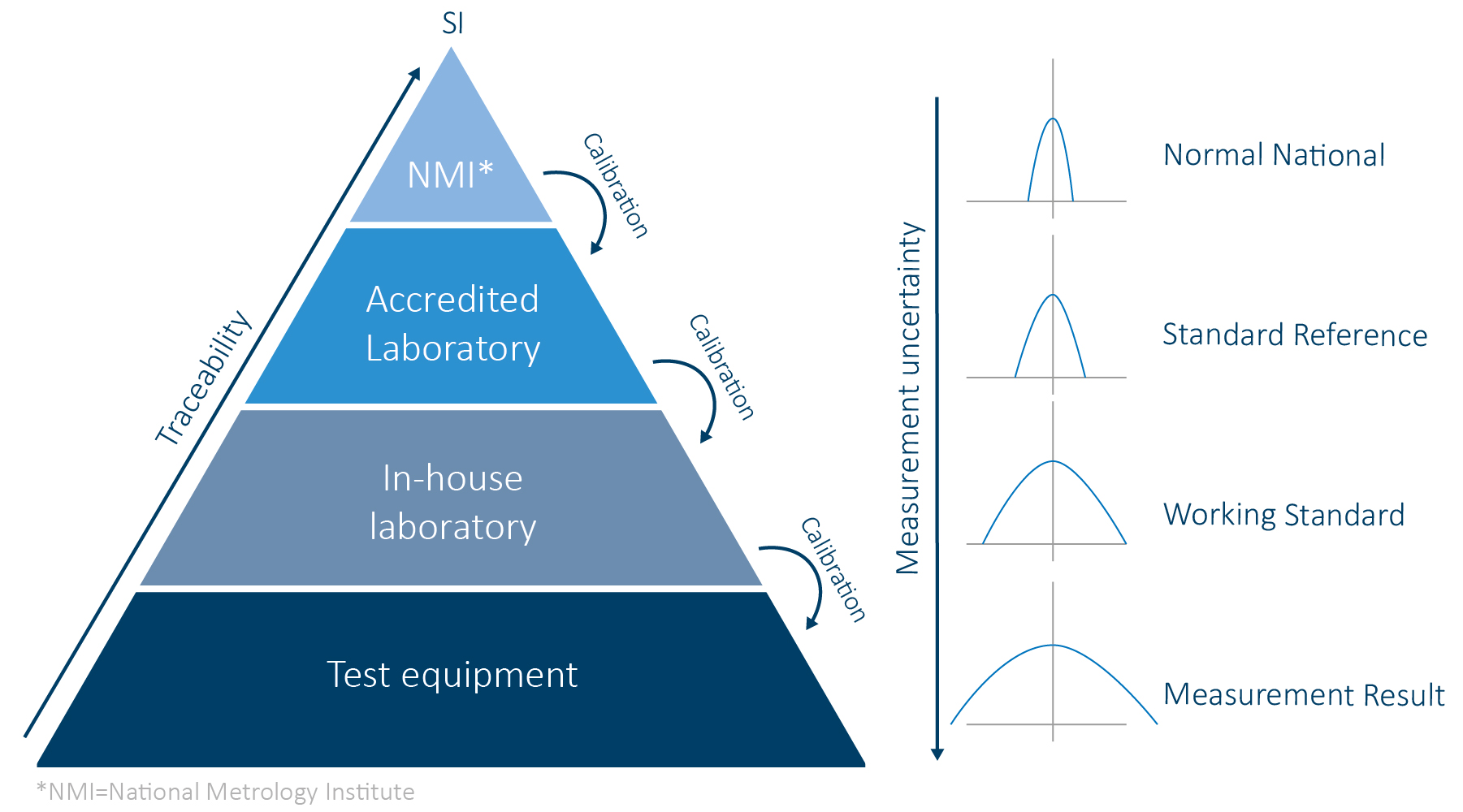

- Traceability

NMI = National Metrological Institute

Metrological traceability (VIM 2.41): Property of a measurement result, whereby the result can be traced back to a reference, through a documented, uninterrupted chain of calibrations, each of which contributing to the measurement uncertainty.- Kalibriererinnerung

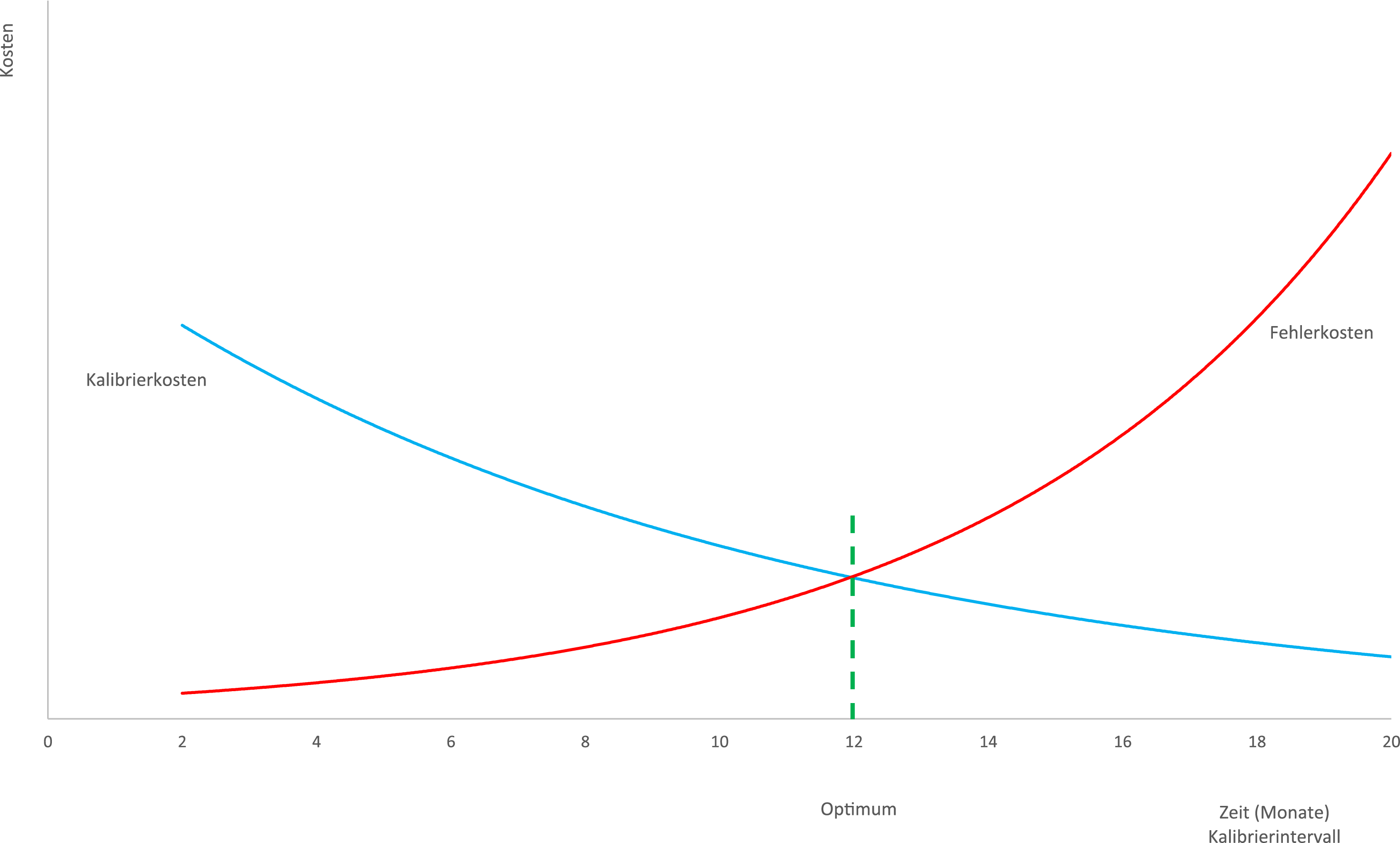

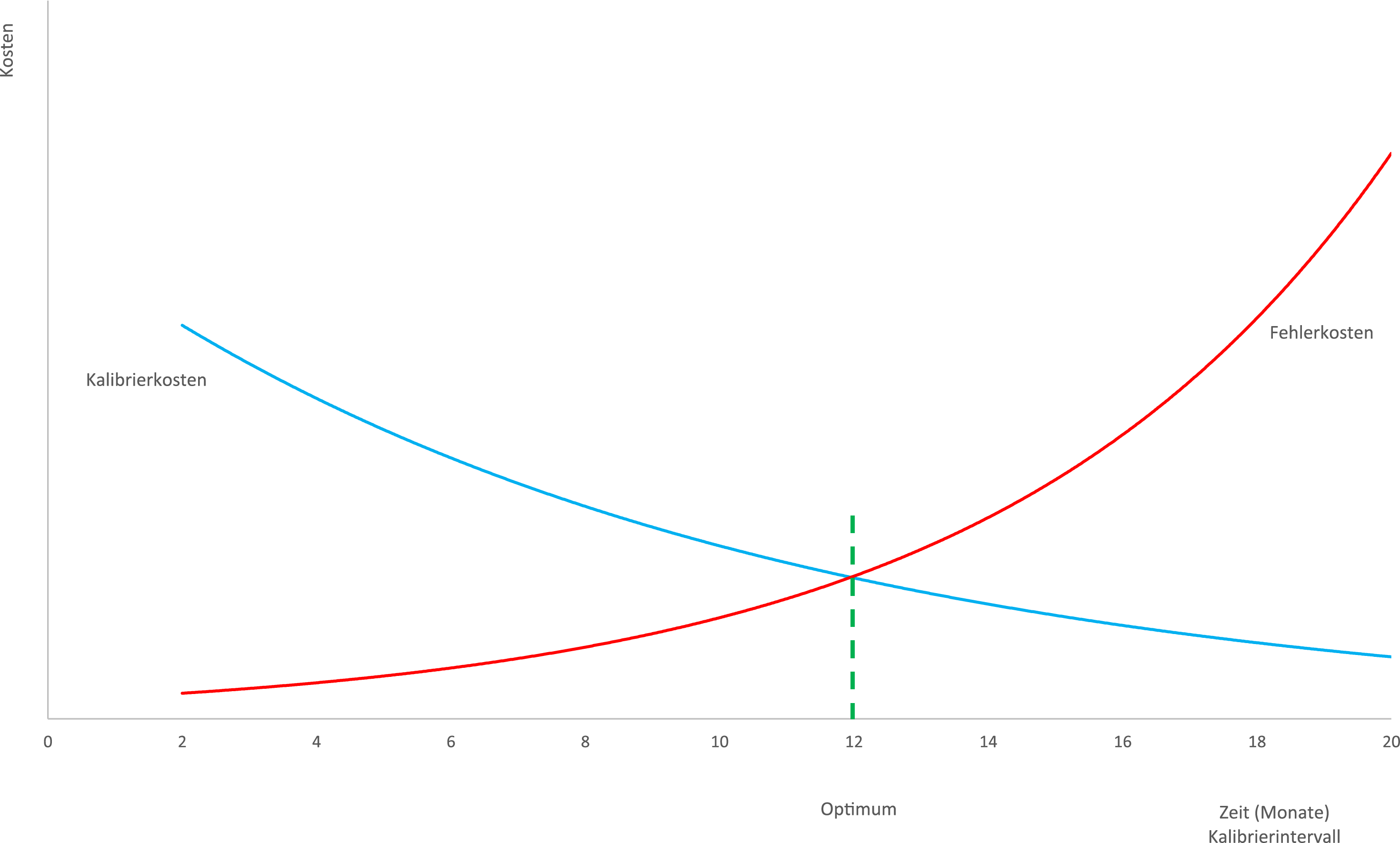

As a special service from our company, you will receive an automatic reminder that your hardness tester needs to be calibrated according to the calibration cycle you have specified. When you buy a new device, this reminder is initially annual, but can be set to the desired interval. You will usually receive the reminder about 1 month before the due date.

With regard to the determination of the calibration rhythm, an optimum should be found between calibration costs and error costs.

- Service

We are happy to answer any questions you might have about hardness testing!

Telephone +49 7305 9642-0

Fax +49 7305 9642-22

EmailThis email address is being protected from spambots. You need JavaScript enabled to view it. Opening hours:

Monday – Thursday: 07.00 a.m. - 16.00 p.m.

Friday: 07.00 a.m. - 12.00 p.m.- KalRock

Digital length measuring device with electronic unit for calibrating the penetration depth measuring device of Rockwell hardness testers.

- normal

Penetration depth path +/- 0,4 mm

- DIN EN ISO 2039-1

- DIN EN ISO 6508-2

0.1 μm

Measuring device for the calibration of the penetration depth measuring device of Rockwell hardness testing machines. Available with DAkkS calibration certificate.

Power supply: 100 – 240 VAC; 50 / 60 Hz

Protection type: IP 30

Measurements: Electronic unit: 290 x 260 x 210 mm

Measuring device: Durchmesser 90 mm, Länge 125 mm

Weight: Electronic unit: 2,5 kg

Measuring device: 3,2 kg

Fine adjustment of length

Measuring device: ± 0,4 mm

Display accuracy

Measuring device: ± 0,2 μm

RS-232 und USB Interface

NMI = National Metrological Institute

Metrological traceability (VIM 2.41): Property of a measurement result, whereby the result can be traced back to a reference, through a documented, uninterrupted chain of calibrations, each of which contributing to the measurement uncertainty.

As a special service from our company, you will receive an automatic reminder that your hardness tester needs to be calibrated according to the calibration cycle you have specified. When you buy a new device, this reminder is initially annual, but can be set to the desired interval. You will usually receive the reminder about 1 month before the due date.

With regard to the determination of the calibration rhythm, an optimum should be found between calibration costs and error costs.

We are happy to answer any questions you might have about hardness testing!

Telephone +49 7305 9642-0

Fax +49 7305 9642-22

Email service@bareiss.de

Opening hours:

Monday – Thursday: 07.00 a.m. - 16.00 p.m.

Friday: 07.00 a.m. - 12.00 p.m.

„With the patented KalRock, you can verify the penetration depth measuring device of your Rockwell hardness tester. With a resolution of 0.3 µm, it controls the length measuring system of the hardness testers, under a maximum preload of 10 kg.“

Downloads

„For more information, use our download service.“

Factory Tour

„Take a look at our production facility in Oberdischingen and discover the precision with which we manufacture our hardness testers.“

Accessories

Request a quote