- Product Overview

- Industry sectors

- Accredited service

- ISO 17025 calibration

- Manufacturer & calibration laboratory

- Rental device & contract measurement

- Seminars & training

- Support & infos

- Company

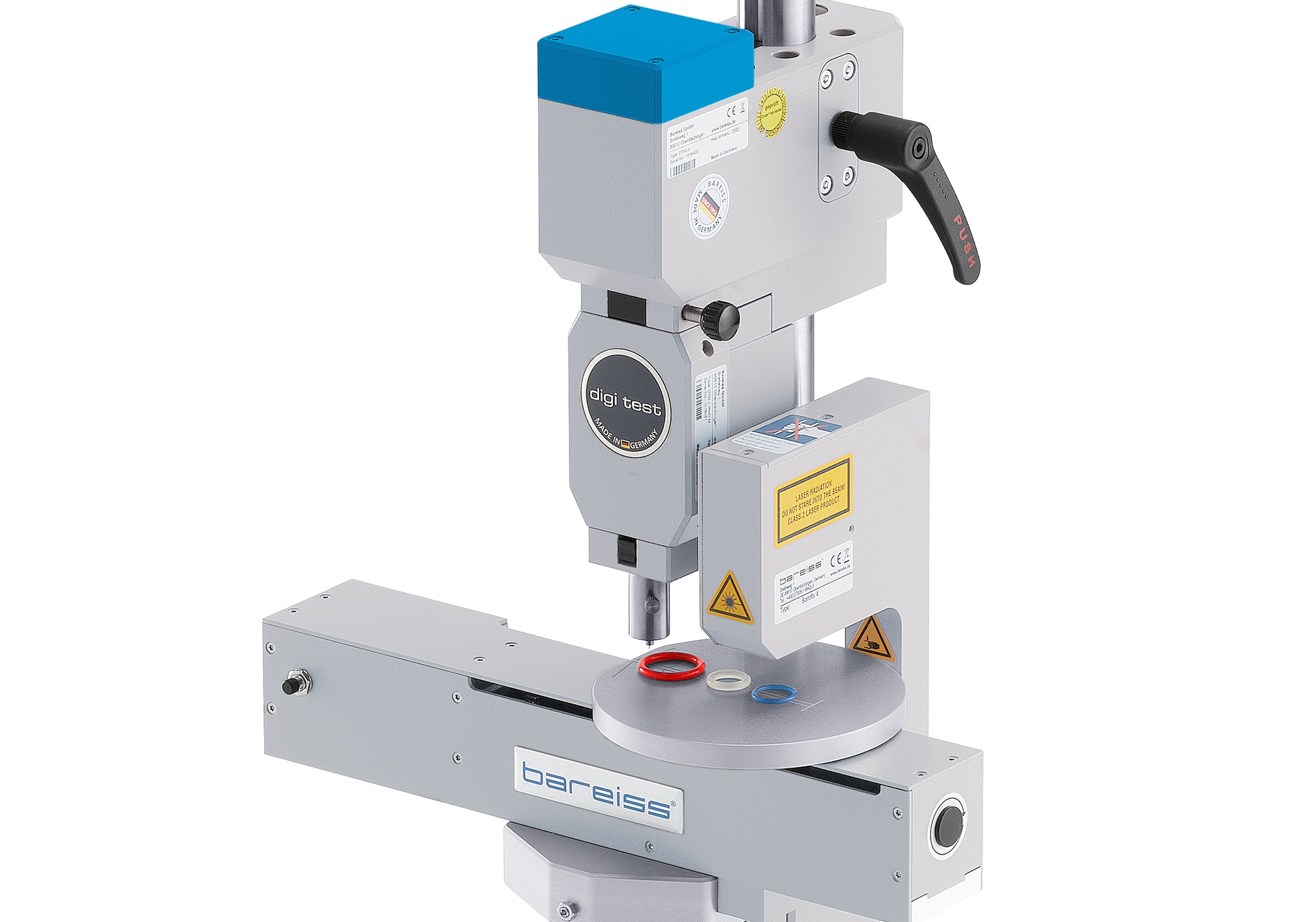

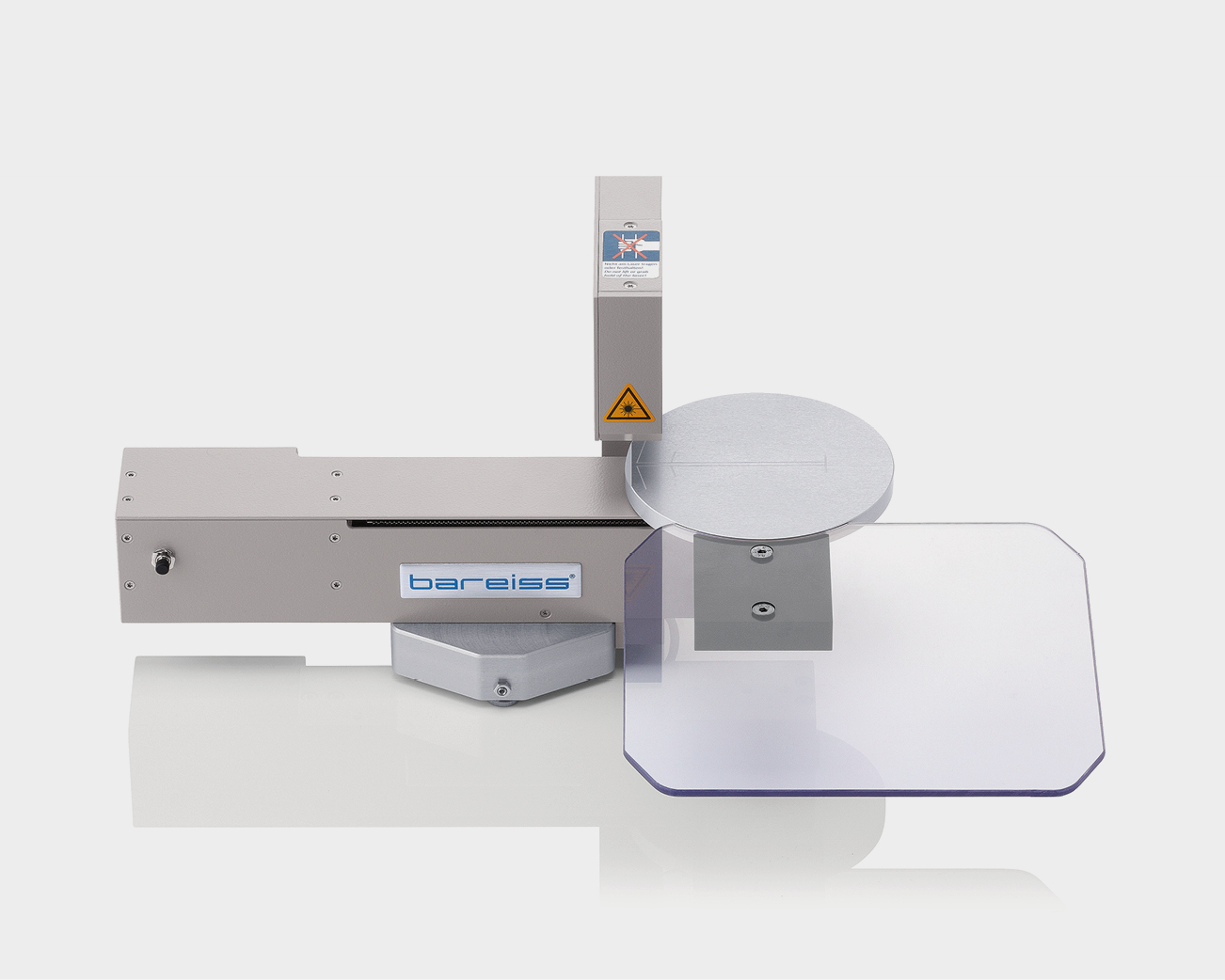

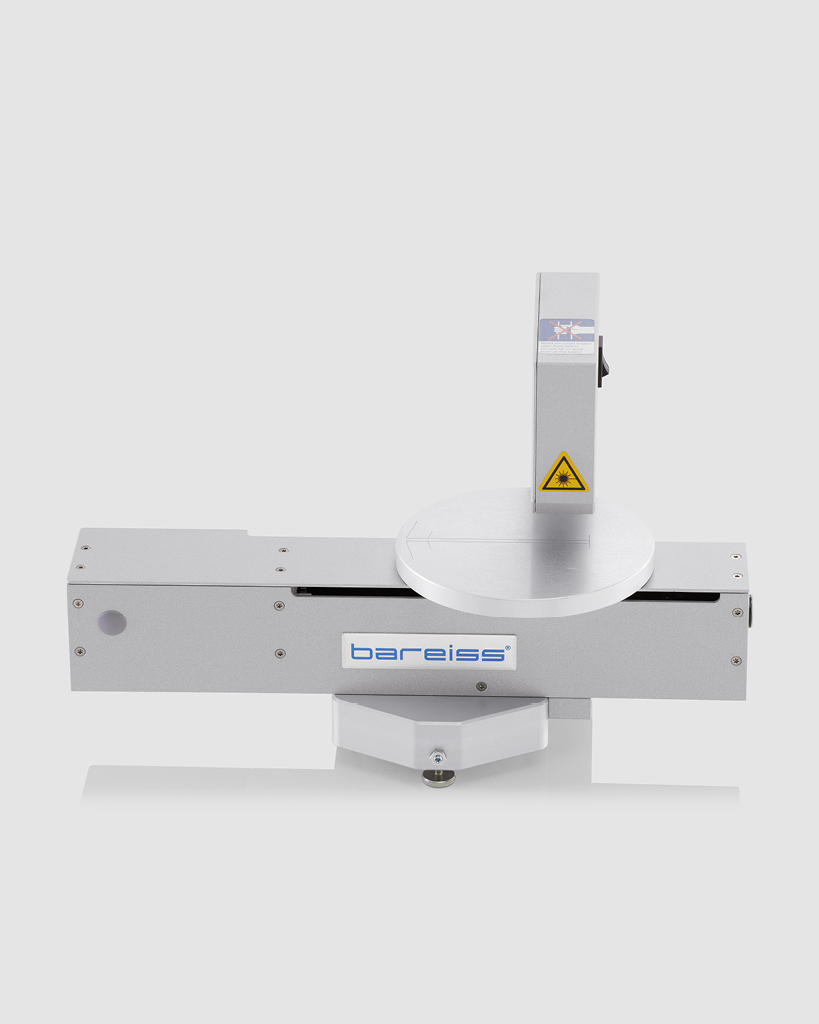

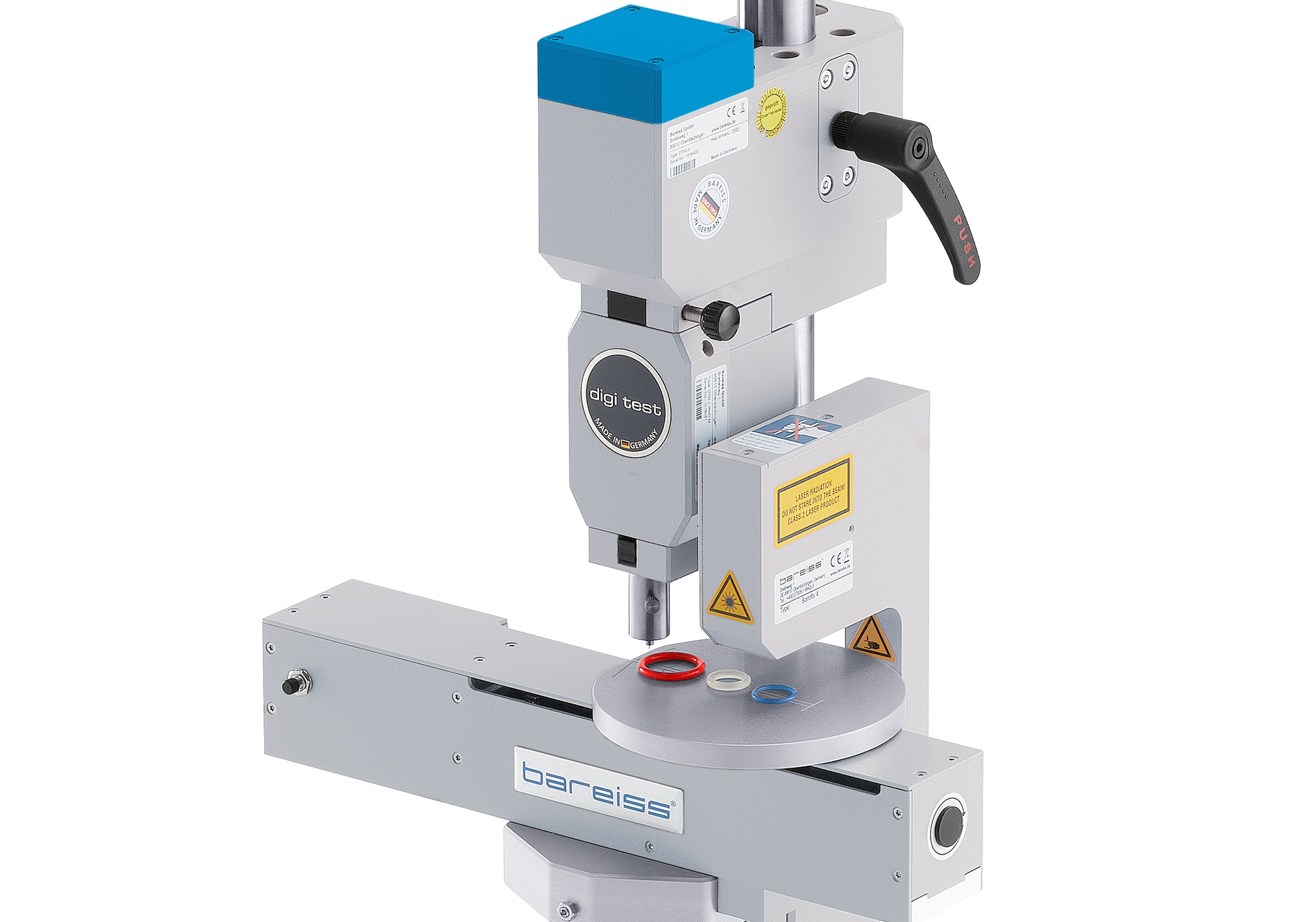

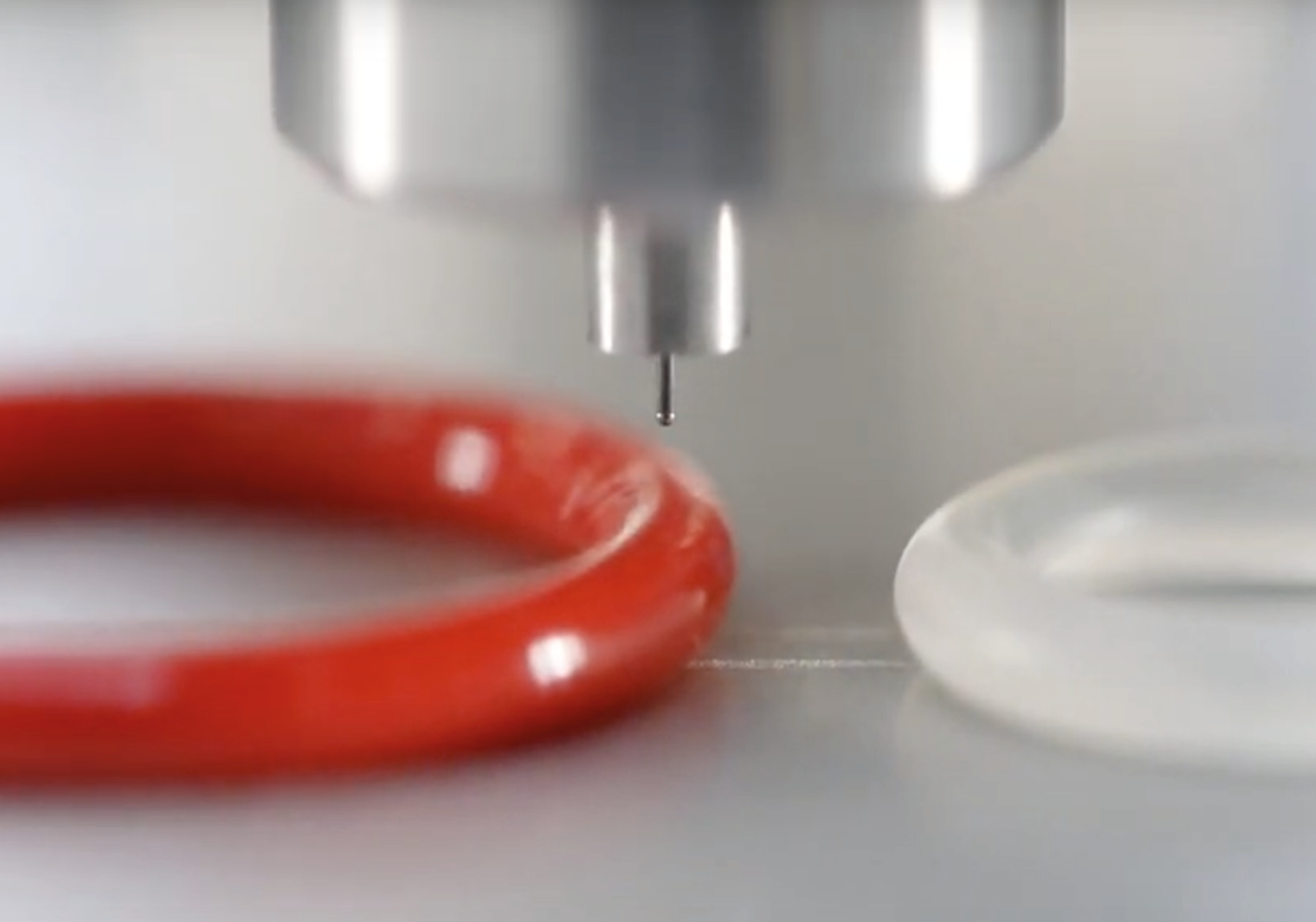

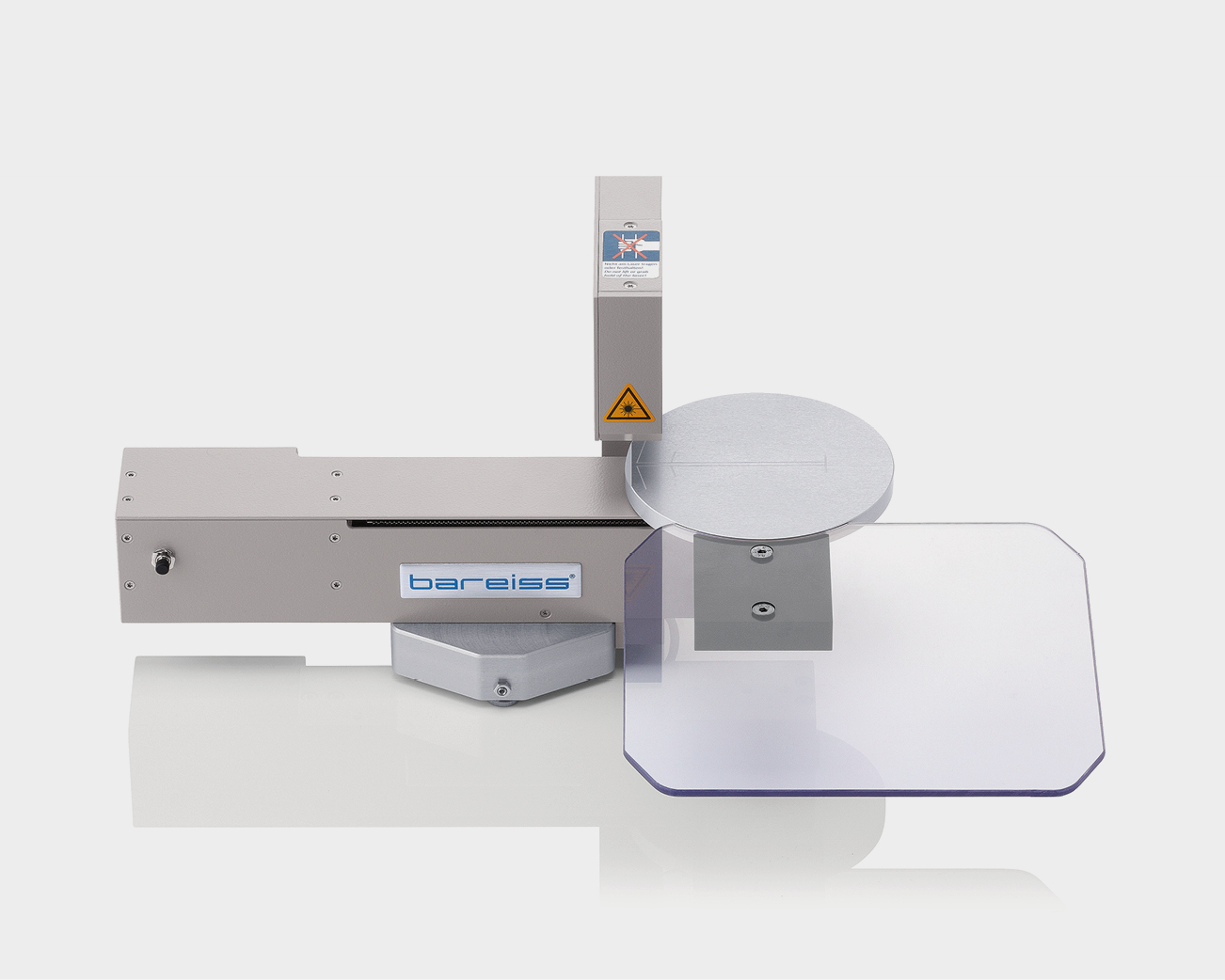

With the help of the positioning device Barofix 4, you can measure the hardness and thickness of plane-parallel sheets and O-rings fully automatically and without any operator influence. The commissioning is very easy: The centering device Barofix 4 is fixed on the measuring table of the digi test II. With the push of a button, a fully automatic adjustment takes place, minimizing user influence during centering.

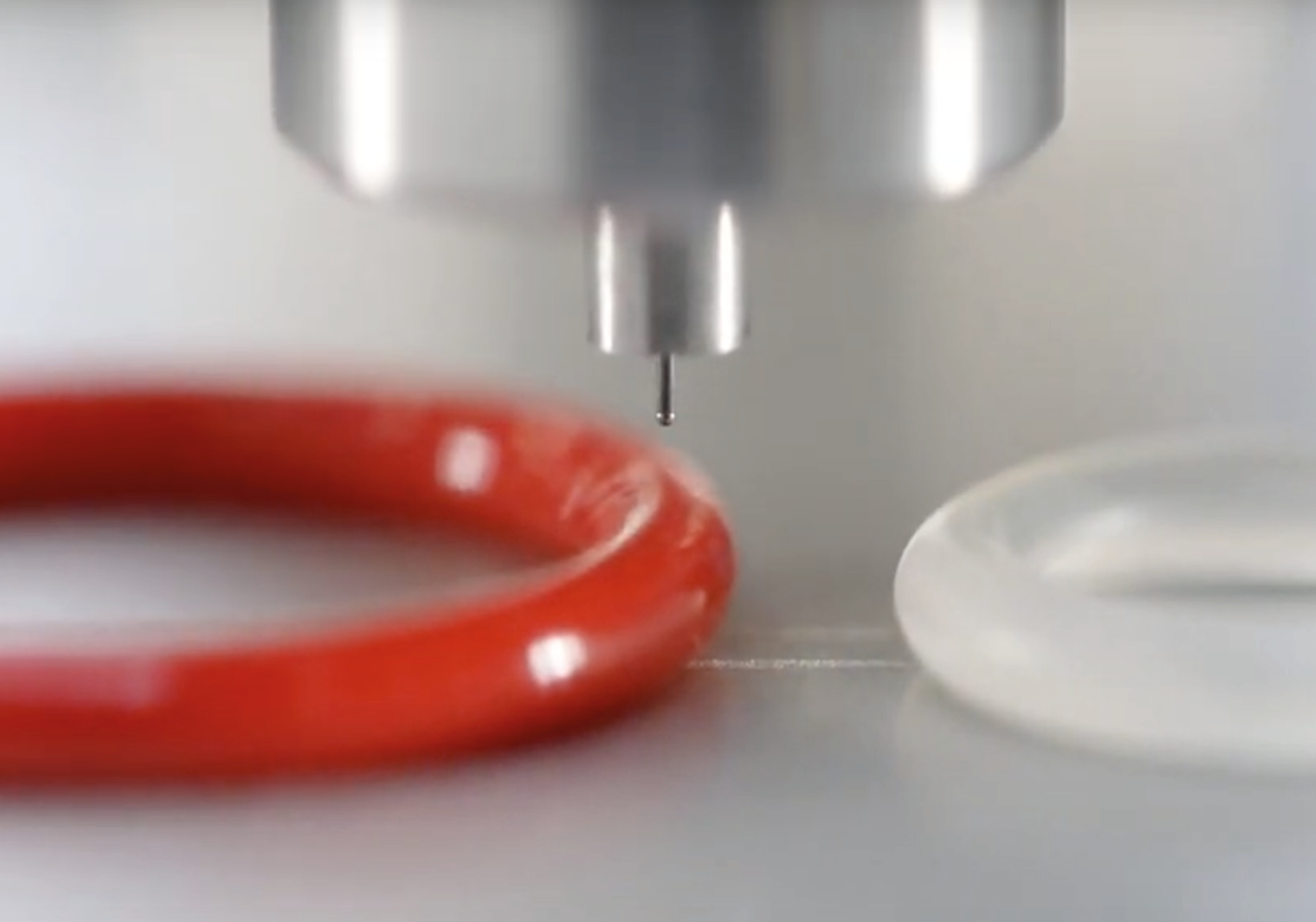

Manually place the samples on the measuring table of the positioning device between the markings. Multiple different samples can also be placed simultaneously. The position of the samples is detected using a laser. Afterwards, the Barofix 4 positions the samples fully automatically precisely under the indenter of the testing device. Thickness measurement and multiple measurements are integrated functions of the Barofix 4. For the measurement points, you can choose between the highest measurement point and the centered measurement point.

Time saving thanks to multiple measurements

The function of multiple measurements of the Barofix 4 allows generating measuring values for multiple samples in one measuring procedure. One or two measurements per O-ring are possible in the process.

Barofix 4

Connection cable

Operating manual

Experience a seamless adjustment process

When changing the measuring device, it is necessary to adjust the distance between the tip of the indenter and the laser beam. With the Barofix 4, this adjustment can be automated at the push of a button, significantly reducing the potential for human errors.

High-precision measuring position thanks to laser

A high-precision laser is integrated to fin the measuring position of the sample compliable with the standards. The centering of the sample is done automatically and independently of the operator below the measuring device.

Measurement of hardness and thickness measuring in one step

With the Barofix 4, it is possible to determine the thickness in addition to the hardness of the sample. Through the 2-in-1 measuring method, a work step in determining or verifying the specifications can be saved.

Other features

Plane-parallel sheets, molded parts, and O-rings without user influence.

Fully automatic and laser-assisted centering device for hardness measurement on plane-parallel sheets, molded parts, and O-rings without operator influence. The Barofix 4 is used in combination with the digi test II.

Plexiglass base plate

Plate-shaped test specimens with a minimum of 0.7 mm depending on the measurement method

Small O-rings and prefabricated parts with a radius of curvature greater than 0.8 mm

Cord thickness from/to: 1,5-10 mm

0.1 hardness units; 0,01 mm thickness measurement

Dim. W x H x D: 31,5 x 19,5 x 14 cm

Gewicht: 3,00 kg

Power supply: digi test II

Protection class: IP 20

Working temperature: 0-60°C

Repeat accuracy thickness measuring: 0,03 mm

Resolution thickness measuring: 0,01 mm

Positioning accuracy table: 0,08 mm

digi test II

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

Fully automatic positioning of O-Rings and sheet material for hardness testing with the digi test II.

![]() Bareiss Silverline 25

Bareiss Silverline 25

New colors, lived responsibility – coatings for a better future

The transition to the new coating will begin mid-year. During the transition period, some devices may still be delivered with previous coating. We kindly ask for your understanding that the new coating cannot be guaranteed.

Plate-shaped test specimens with a minimum of 0.7 mm depending on the measurement method

Small O-rings and prefabricated parts with a radius of curvature greater than 0.8 mm

Cord thickness from/to: 1,5-10 mm

0.1 hardness units; 0,01 mm thickness measurement

Dim. W x H x D: 31,5 x 19,5 x 14 cm

Gewicht: 3,00 kg

Power supply: digi test II

Protection class: IP 20

Working temperature: 0-60°C

Repeat accuracy thickness measuring: 0,03 mm

Resolution thickness measuring: 0,01 mm

Positioning accuracy table: 0,08 mm

digi test II

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email sales@bareiss.de

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

With the help of the positioning device Barofix 4, you can measure the hardness and thickness of plane-parallel sheets and O-rings fully automatically and without any operator influence. The commissioning is very easy: The centering device Barofix 4 is fixed on the measuring table of the digi test II. With the push of a button, a fully automatic adjustment takes place, minimizing user influence during centering.

Manually place the samples on the measuring table of the positioning device between the markings. Multiple different samples can also be placed simultaneously. The position of the samples is detected using a laser. Afterwards, the Barofix 4 positions the samples fully automatically precisely under the indenter of the testing device. Thickness measurement and multiple measurements are integrated functions of the Barofix 4. For the measurement points, you can choose between the highest measurement point and the centered measurement point.

Time saving thanks to multiple measurements

The function of multiple measurements of the Barofix 4 allows generating measuring values for multiple samples in one measuring procedure. One or two measurements per O-ring are possible in the process.

Experience a seamless adjustment process

When changing the measuring device, it is necessary to adjust the distance between the tip of the indenter and the laser beam. With the Barofix 4, this adjustment can be automated at the push of a button, significantly reducing the potential for human errors.

High-precision measuring position thanks to laser

A high-precision laser is integrated to fin the measuring position of the sample compliable with the standards. The centering of the sample is done automatically and independently of the operator below the measuring device.

Measurement of hardness and thickness measuring in one step

With the Barofix 4, it is possible to determine the thickness in addition to the hardness of the sample. Through the 2-in-1 measuring method, a work step in determining or verifying the specifications can be saved.

Other features

Barofix 4

Connection cable

Operating manual

Plexiglass base plate

We have experience.

We have been active in the field of measurement technology since 1954 - now in the third generation.

We stay true to ourselves.

All of our products are developed and manufactured in Germany.

We are accredited.

Our DAkkS accredited calibration laboratory is certified according to DIN EN/IEC 17025.

We are committed.

We are a member of the DIN committee and set standards there in the area of hardness.

We have inventive talent.

We have developed and registered over 25 patents in the last few decades.

We distribute worldwide.

We and our partners are there for you anywhere in the world.