- Product Overview

- Industry sectors

- Accredited service

- Support & Experience Days

- Company

To determine the hardness of foamed materials of automotive steering wheels with plastic or leather covering, use our HPE III Basic L. With its short measuring range and the small 5 mm ball-shaped indenter, this digital handheld hardness tester is specifically designed for thin material coatings.

The hardness tester can be easily palced on the steering wheel and centered using the corresponding centering device. The weight attached to the measuring rod applies a defined force to the test device, ensuring consistent conditions even during multiple measurements along the circumference of the steering wheel. After the measurement time has elapsed, the HPE III Basic L acknowledges successful completion with an audible signal and displays the determined hardness on the screen. Up to 300 measurement values can be stored in the internal memory and exported via the serial RS-232 interface.

Other features

HPE III Basic L handheld hardness tester

Bracket for steering wheel

Adapter sleeve for various steering wheels

USB data cable

Lithium-ion battery

The HPE III Basic L with centering device is specifically designed for hardness testing on steering wheels.

Control rings

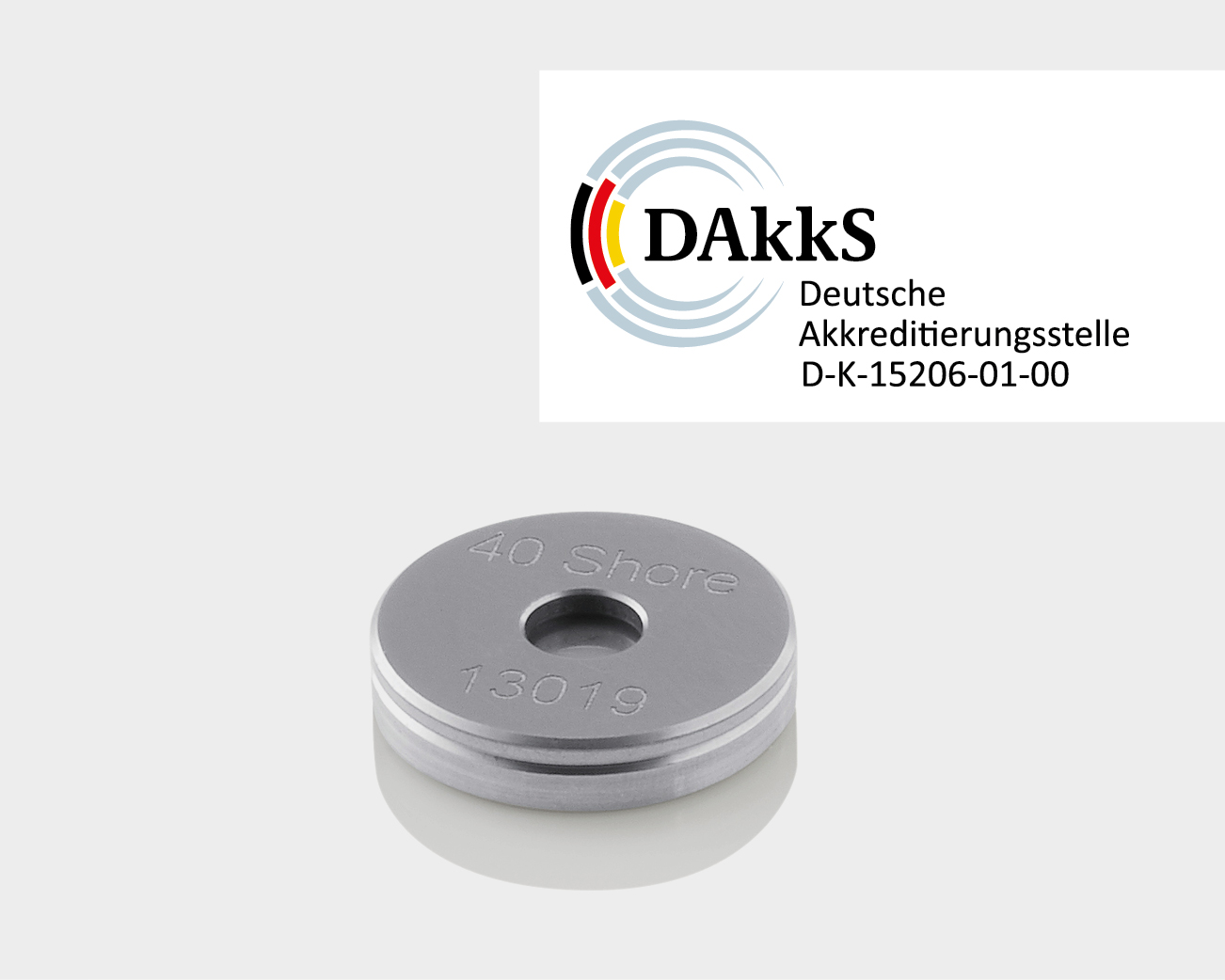

with DAkkS accredited calibration certificate

Reference blocks

with DAkkS accredited calibration certificate,

single/ 3-piece or 6-piece set

Software

Free forms

0.1

Dim. W x H x D: 7 x 16 x 5,5 cm

Weight: 0,32 kg

Power supply: Battery

Protection class: IP 30

Operating time: 2000 working hours

RS 232

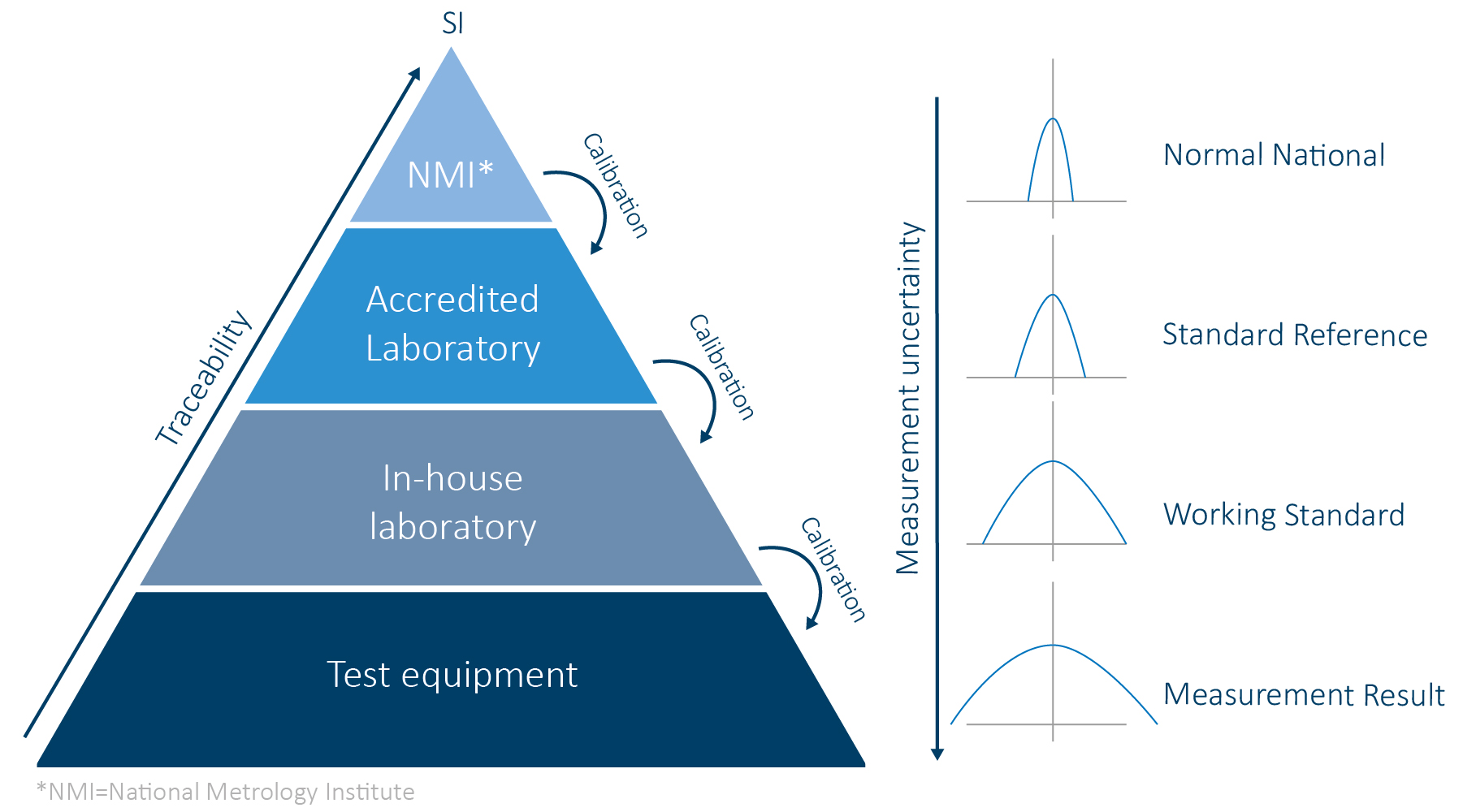

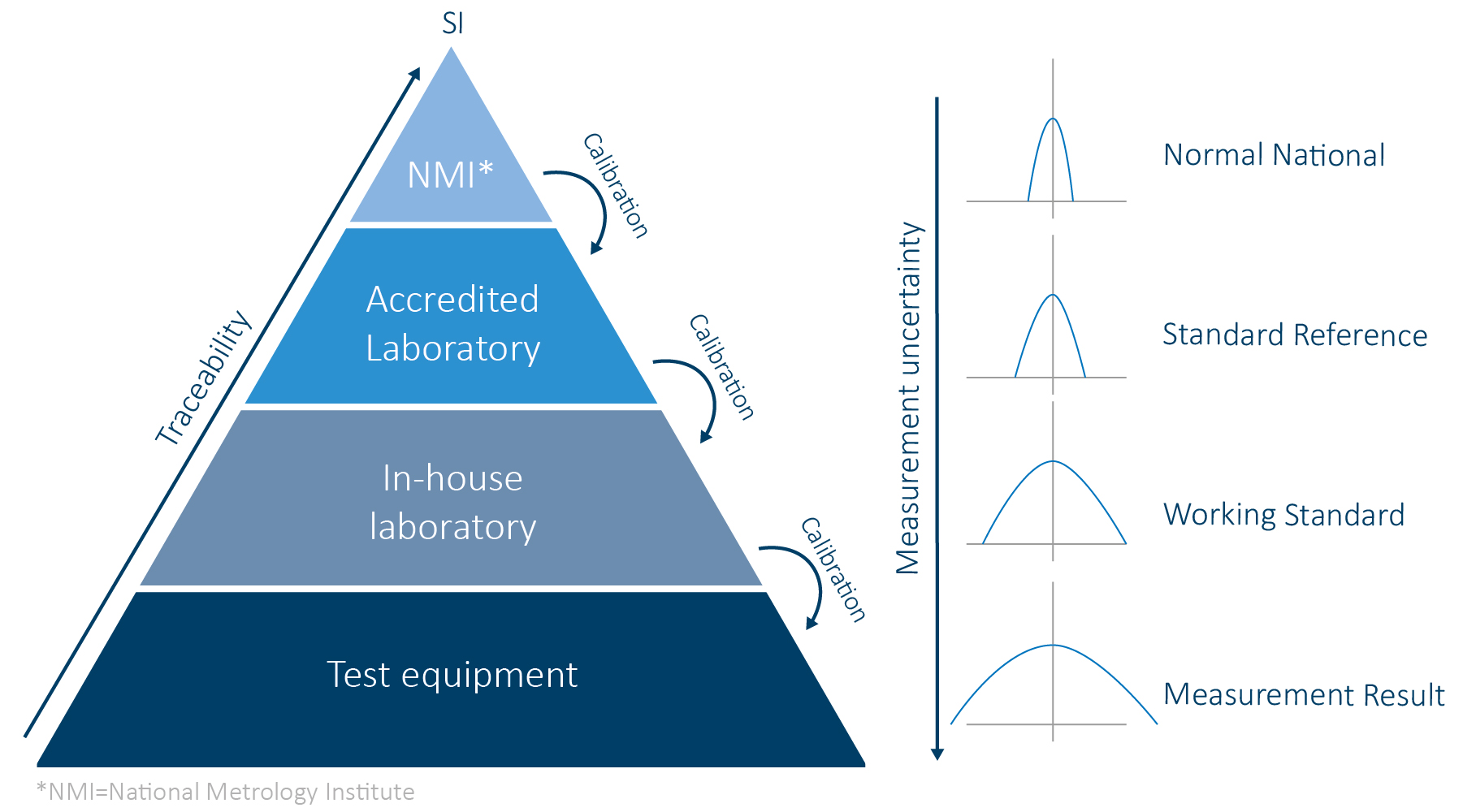

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email

Opening hours:

Monday - Thursday: 07.00 - 16.00 Uhr

Friday: 07.00 - 12.00 Uhr

Hardness tester with special centering device and bracket for hardness measurements on foamed materials of automotive steering wheels.

Free forms

0.1

Dim. W x H x D: 7 x 16 x 5,5 cm

Weight: 0,32 kg

Power supply: Battery

Protection class: IP 30

Operating time: 2000 working hours

RS 232

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email sales@bareiss.de

Opening hours:

Monday - Thursday: 07.00 - 16.00 Uhr

Friday: 07.00 - 12.00 Uhr

To determine the hardness of foamed materials of automotive steering wheels with plastic or leather covering, use our HPE III Basic L. With its short measuring range and the small 5 mm ball-shaped indenter, this digital handheld hardness tester is specifically designed for thin material coatings.

The hardness tester can be easily palced on the steering wheel and centered using the corresponding centering device. The weight attached to the measuring rod applies a defined force to the test device, ensuring consistent conditions even during multiple measurements along the circumference of the steering wheel. After the measurement time has elapsed, the HPE III Basic L acknowledges successful completion with an audible signal and displays the determined hardness on the screen. Up to 300 measurement values can be stored in the internal memory and exported via the serial RS-232 interface.

Other features

HPE III Basic L handheld hardness tester

Bracket for steering wheel

Adapter sleeve for various steering wheels

USB data cable

Lithium-ion battery

Control rings

with DAkkS accredited calibration certificate

Reference blocks

with DAkkS accredited calibration certificate,

single/ 3-piece or 6-piece set

Software

We have experience.

We have been active in the field of measurement technology since 1954 - now in the third generation.

We stay true to ourselves.

All of our products are developed and manufactured in Germany.

We are accredited.

Our DAkkS accredited calibration laboratory is certified according to DIN EN/IEC 17025.

We are committed.

We are a member of the DIN committee and set standards there in the area of hardness.

We have inventive talent.

We have developed and registered over 25 patents in the last few decades.

We distribute worldwide.

We and our partners are there for you anywhere in the world.