- Product Overview

- Industry sectors

- Accredited service

- ISO 17025 calibration

- Manufacturer & calibration laboratory

- Rental device & contract measurement

- Seminars & training

- Support & infos

- Company

Shore A for plate material

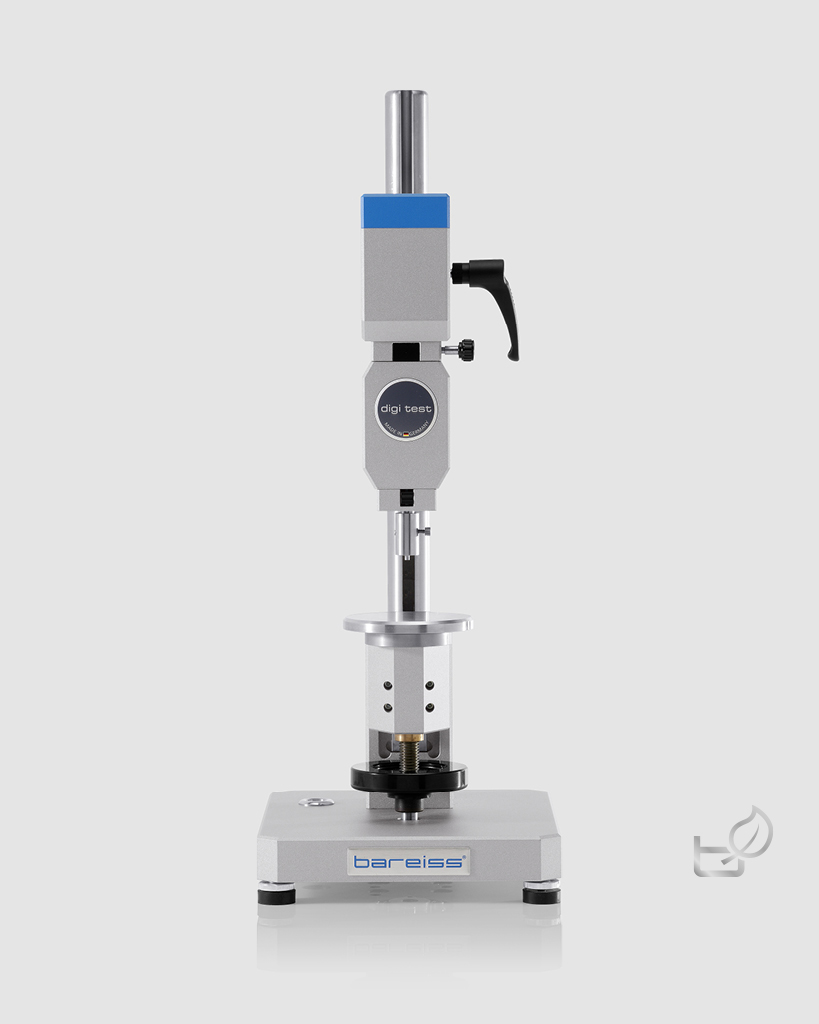

The modular digi test II offers you maximum flexibility in hardness testing for elastomers, plastics, flexible materials, composite materials, and foams. With just a few simple stepsand no tools required, the numerous measuring devices for Shore, VLRH, or IRHD can be easily swapped, allowing for quick transition between different measuring methods.

Hardness measurements take place fully automatically, minimizing user influence to a minimum. An attached electronic unit detects the selected measuring device, automatically adjusts to the appropriate measuting method, and guides through the testing procedure via the user-friendly menu. Variable centering devices assist in aligning single samples or position multiple test pieces, for example automatically or through laser guidance. All measured values and information can be directly displayed and conveniently exported into the BareissOne software platform.

Shore D for plate material

Modular expandable

Interchangeable measuring devices enable effortless switching between the numerous measuring methods in the Shore, IRHD, and VLRH ranges without the need for tools and with just a few simple steps. With a variety of positioning and measuring devices available, the digi test II is the ideal choice for laboratory, production, quality control, and development when testing a wide range of product portfolios.

Shore A/B/0 for molded parts

Shore D/C/D0 for molded parts

Micro Shore A

Micro Shore D

Test stand

Mounting arm for measuring units

Electronic unit

USB data cable

Operating manual

Shore 00

Centering device with vise

Centrofix for cables

Shore 000

Centrofix for hoses

Customized Centrofix

Customized Rotofix

Rotofix with sample holder for rheology samples

Rotofix for multiple rubber discs

Barofix for O-rings

Barofix for large O-rings

Shore AM

Barofix 4 for laser-controlled positioning of O-rings

IRHD N

IRHD L

IRHD M

IRHD H

VLRH

Many shapes – one solution

The modular expandability of the digi test II enables the measurement of all samples geometries. Whether you want to conduct measurements on flat, sloped, concave, or convex geometries, you will obtain precise measuring values starting from a sample thickness of 0.7 mm, thanks to the approach system.

Ssecure measuring values without user influence

In addition to perfect alignment as a tabletop unit, the digi test II ensures the optimal measuring position of testspecimens through its numerous positioning devices. Most accurate measurements without user influence and manual pre-adjustment are guaranteed, giving you time for the important things.

Comprehensive analysis though various measuring methods

Measure not only the hardness grade of your test speciment but also the material's flow curve during the test. With the option for hysteresis measurements, the digi test II provides additional insights into the material's characteristic properties.

BareissOne – The software platform for your measuring values

The unique and modular software platform BareissOne allows you to centrally store and analyze all measuring values from your Bareiss testing devices. The user-friendly interface offers statistical analysis of measurement values with user administration and automatic generation of test protocols. Whether it is a standard test for individual measurements or a test series with a complex text sequence, BareissOne meets your specific requirements.

Other features

Flat, sloped, convex, and concave geometries of composite materials, flexible materials, elastomers, plastics and foams

The digi test II enables precise and user-independent hardness measurements on elastomers, plastics, flexible materials, composite materials, and foams. This modular expandable measuring system is utilized in research and development as well as in production and quality control to determine the material hardness of a wide range of portfolios and ensure quality standards.

DAkkS accredited calibration certificate

for measuring device

Magnifying glass

with 2.5x magnification,

flexible, pivoting

Standard blocks

with DAkkS accredited calibration certificate

Software

Measurement data system

and analysis system

O-rings

Plate material

Molded parts and thin samples with a material thickness of at least 0.7 mm depending on the measuring method

0.1 hardness units

Test stand

Dim. W x H x D: 20 x 55 x 25 cm

Weight: 9,00 kg

With pick-up bracket and measuring device

Dim. W x H x D: min. 20 x 55 x 25 cm

max. 20 x 60 x 31 cm

Weight: 15,60 kg

Elektronic unit

Dim. W x H x D: min. 26 x 11,5 x 26,5 cm

max. 26 x 11,5 x 34 cm

Weight: 2,32 kg

Pick-up bracket

Dim. W x H x D: 11,5 x 12,5 x 17 cm

Weight: 1,99 kg

Power supply: 100-240 VAC; 50/60 Hz

Protection class: IP 50

USB or RS-232 interfaces for data transfer

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone+49 7305 9642-0

Fax +49 7305 9642-22

Email

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

Modular hardness testing system for fully automatic hardness testing according to Shore, VLRH, and IRHD on composite materials, flexible materials, elastomers, plastics, and foams with variable test geometries.

![]() Bareiss Silverline 25

Bareiss Silverline 25

New colors, lived responsibility – coatings for a better future

The transition to the new coating will begin mid-year. During the transition period, some devices may still be delivered with previous coating. We kindly ask for your understanding that the new coating cannot be guaranteed.

O-rings

Plate material

Molded parts and thin samples with a material thickness of at least 0.7 mm depending on the measuring method

0.1 hardness units

Test stand

Dim. W x H x D: 20 x 55 x 25 cm

Weight: 9,00 kg

With pick-up bracket and measuring device

Dim. W x H x D: min. 20 x 55 x 25 cm

max. 20 x 60 x 31 cm

Weight: 15,60 kg

Elektronic unit

Dim. W x H x D: min. 26 x 11,5 x 26,5 cm

max. 26 x 11,5 x 34 cm

Weight: 2,32 kg

Pick-up bracket

Dim. W x H x D: 11,5 x 12,5 x 17 cm

Weight: 1,99 kg

Power supply: 100-240 VAC; 50/60 Hz

Protection class: IP 50

USB or RS-232 interfaces for data transfer

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone+49 7305 9642-0

Fax +49 7305 9642-22

Email sales@bareiss.de

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

The modular digi test II offers you maximum flexibility in hardness testing for elastomers, plastics, flexible materials, composite materials, and foams. With just a few simple stepsand no tools required, the numerous measuring devices for Shore, VLRH, or IRHD can be easily swapped, allowing for quick transition between different measuring methods.

Hardness measurements take place fully automatically, minimizing user influence to a minimum. An attached electronic unit detects the selected measuring device, automatically adjusts to the appropriate measuting method, and guides through the testing procedure via the user-friendly menu. Variable centering devices assist in aligning single samples or position multiple test pieces, for example automatically or through laser guidance. All measured values and information can be directly displayed and conveniently exported into the BareissOne software platform.

Modular expandable

Interchangeable measuring devices enable effortless switching between the numerous measuring methods in the Shore, IRHD, and VLRH ranges without the need for tools and with just a few simple steps. With a variety of positioning and measuring devices available, the digi test II is the ideal choice for laboratory, production, quality control, and development when testing a wide range of product portfolios.

Many shapes – one solution

The modular expandability of the digi test II enables the measurement of all samples geometries. Whether you want to conduct measurements on flat, sloped, concave, or convex geometries, you will obtain precise measuring values starting from a sample thickness of 0.7 mm, thanks to the approach system.

Ssecure measuring values without user influence

In addition to perfect alignment as a tabletop unit, the digi test II ensures the optimal measuring position of testspecimens through its numerous positioning devices. Most accurate measurements without user influence and manual pre-adjustment are guaranteed, giving you time for the important things.

Comprehensive analysis though various measuring methods

Measure not only the hardness grade of your test speciment but also the material's flow curve during the test. With the option for hysteresis measurements, the digi test II provides additional insights into the material's characteristic properties.

BareissOne – The software platform for your measuring values

The unique and modular software platform BareissOne allows you to centrally store and analyze all measuring values from your Bareiss testing devices. The user-friendly interface offers statistical analysis of measurement values with user administration and automatic generation of test protocols. Whether it is a standard test for individual measurements or a test series with a complex text sequence, BareissOne meets your specific requirements.

Other features

Shore A for plate material

Shore D for plate material

Shore A/B/0 for molded parts

Shore D/C/D0 for molded parts

Micro Shore A

Micro Shore D

Shore 00

Shore 000

Shore AM

IRHD N

IRHD L

IRHD M

IRHD H

VLRH

Centering device with vise

Centrofix for cables

Centrofix for hoses

Customized Centrofix

Customized Rotofix

Rotofix with sample holder for rheology samples

Rotofix for multiple rubber discs

Barofix for O-rings

Barofix for large O-rings

Barofix 4 for laser-controlled positioning of O-rings

Test stand

Mounting arm for measuring units

Electronic unit

USB data cable

Operating manual

DAkkS accredited calibration certificate

for measuring device

Magnifying glass

with 2.5x magnification,

flexible, pivoting

Standard blocks

with DAkkS accredited calibration certificate

Software

Measurement data system

and analysis system

We have experience.

We have been active in the field of measurement technology since 1954 - now in the third generation.

We stay true to ourselves.

All of our products are developed and manufactured in Germany.

We are accredited.

Our DAkkS accredited calibration laboratory is certified according to DIN EN/IEC 17025.

We are committed.

We are a member of the DIN committee and set standards there in the area of hardness.

We have inventive talent.

We have developed and registered over 25 patents in the last few decades.

We distribute worldwide.

We and our partners are there for you anywhere in the world.