- Product Overview

- Industry sectors

- Accredited service

- Support & Experience Days

- Company

The digiChamber temperature chamber from Bareiss is the perfect solution to analyze the hardness changes at different temperature ranges. Through collaboration with the renowned provider of temperature solutions "Vötsch Technik", you get temprature simulations with the best accuracy. Maximize your testing capabilities and capacities with our computer-controlled, serial temperature chamber for polymer hardness testing, with a temperature range from -40°C to +180°C. The corresponding hardness tester digi test II is mounted externally to avoid temperature-related measuring faults.

With the rotating table for sample positioning, hardness testing can be automated and conducted in series at freely definable measuring points on each sample. Alternatively, you can align the molded parts individually and manually through the opening of the chamber on the side.

With the "digiCenter" software, you can control temperature levels, conditioning time, and the number of measuring points, as well as manage the determined values in a database. For the display of the temperature-related hardness values, the program offers both graphics and value tables.

Best Quality

High-quality Bareiss hardness tester combined with high-quality temperature chamber from "Vötsch Technik" for best test results.

Scope of delivery according to packing list

Temperature chamber digiChamber

Measuring device Shore A or IRHD N

Software "digiCenter"

Operating manual

Hardness testing under realistic operating conditions

Test how temperature influence has an impact on the hardness of your material and simulate real conditions from -40°C to +180°C.

Simple and intuitive operation

In the intuitive operable "digiCenter" software, you can create test plans for different materials or requirements and save them as templates.

High flexibility of the testing procedure

The digiChamber offers flexible options for defining measuring points on each individual sample and for serial measurement.

Other features

Tire manufacturers, sealing material, hardness testing of rubber compounds of all kinds unter temperature influence

Measuring device

Shore A or IRHD N

Reference elastomer blocks

with DAkkS accredited calibration certificate

DAkkS accredited calibration certificate

Plate material and molded parts with a minimum thickness of 6 mm.

0,1 hardness units

0,1°C

Dim. W x H x D: 85 x 164 x 130 cm

Power supply: 100-240 VAC; 50/60 Hz; 12 A

Protection class: IP 54

Temperature range: -40°C to +180°C

Recommended max. temp.: 150°C

Pressure: 4-12 bar

Consumption: max. 6 m3/h

Sample type: Plate shape samples

Sample standard: Ø 38 mm / 50 mm, others on request

Ethernet

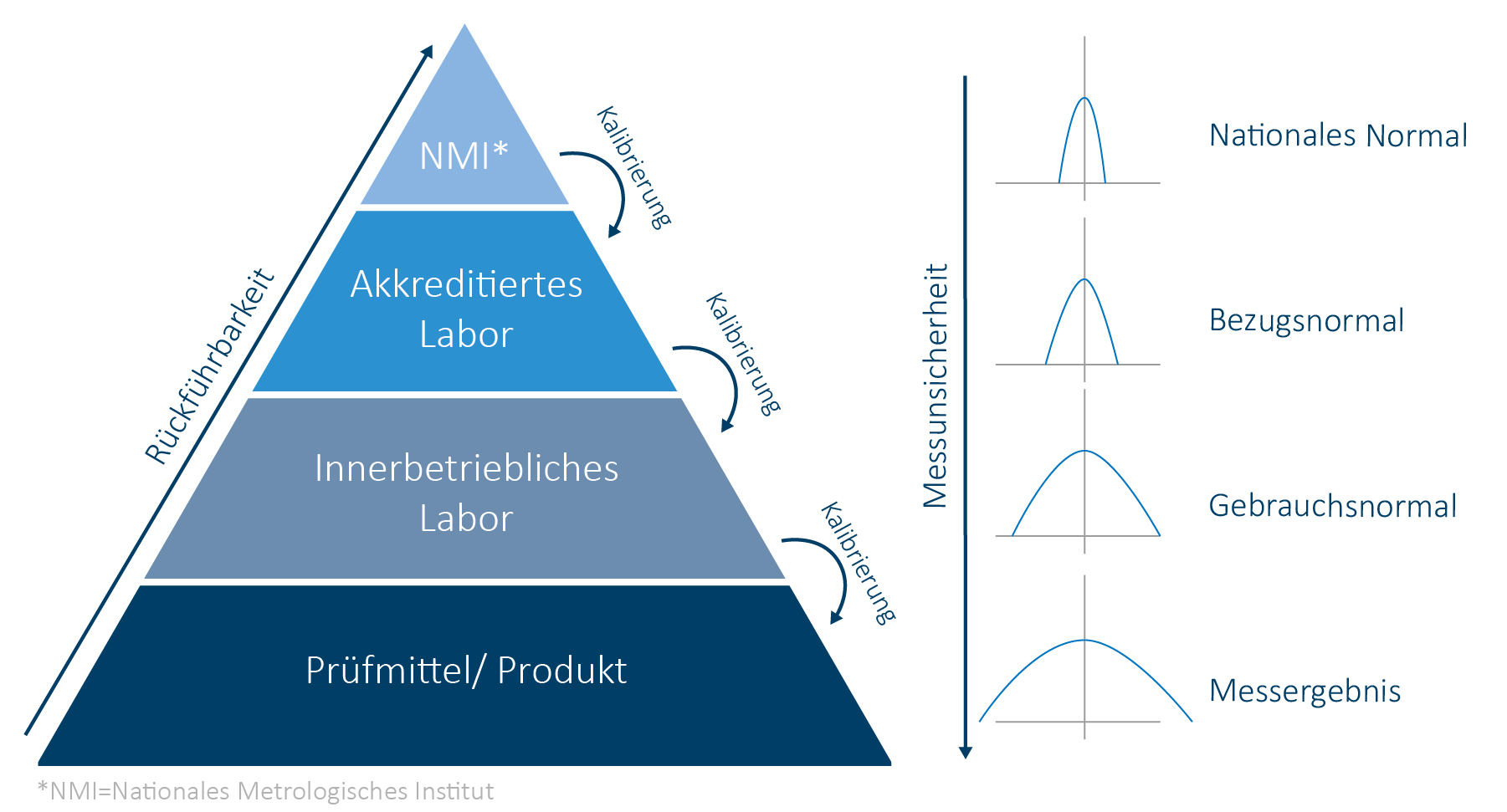

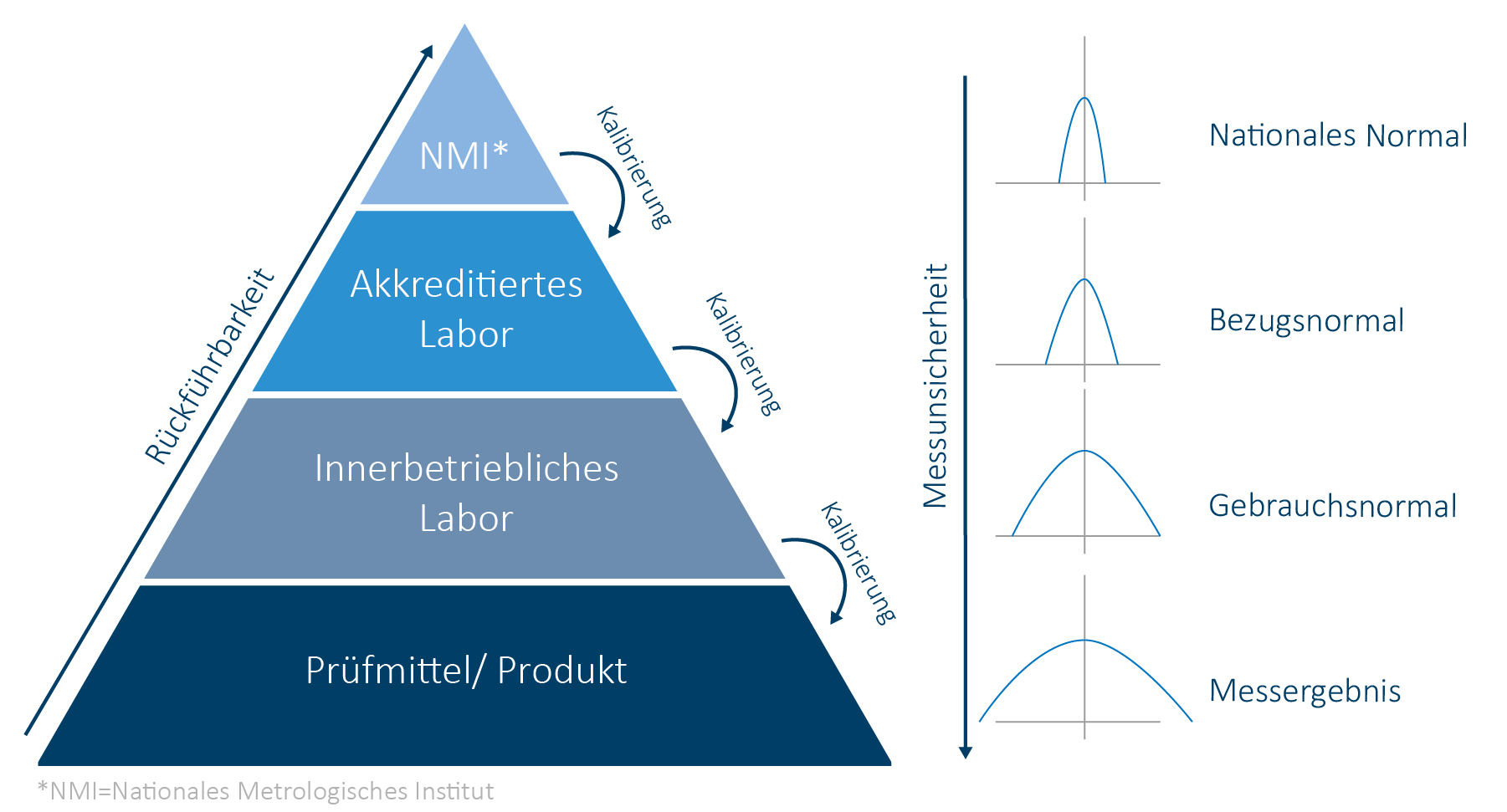

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable. Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS Accredited Service

Since 1996, Bareiss Prüfgerätebau GmbH has been recognized as a DAkkS-accredited calibration laboratory, standing for the highest quality and precision. Our calibrations comply with international standards according to DIN EN ISO/IEC 17025:2018, ensuring reliable and internationally comparable measurement results.

Take advantage of our service offerings:

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results. Benefit from our experience as a manufacturer and accredited calibration laboratory.

-40°C to +180°C

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email

Opening hours:

Monday - Thursday: 07.00 - 16.00 Uhr

Friday: 07.00 - 12.00 Uhr

Temperature chamber for automated hardness testing according to Shore A and IRHD N at extreme temperatures from -40°C to +180°C.

Plate material and molded parts with a minimum thickness of 6 mm.

0,1 hardness units

0,1°C

Dim. W x H x D: 85 x 164 x 130 cm

Power supply: 100-240 VAC; 50/60 Hz; 12 A

Protection class: IP 54

Temperature range: -40°C to +180°C

Recommended max. temp.: 150°C

Pressure: 4-12 bar

Consumption: max. 6 m3/h

Sample type: Plate shape samples

Sample standard: Ø 38 mm / 50 mm, others on request

Ethernet

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable. Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS Accredited Service

Since 1996, Bareiss Prüfgerätebau GmbH has been recognized as a DAkkS-accredited calibration laboratory, standing for the highest quality and precision. Our calibrations comply with international standards according to DIN EN ISO/IEC 17025:2018, ensuring reliable and internationally comparable measurement results.

Take advantage of our service offerings:

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results. Benefit from our experience as a manufacturer and accredited calibration laboratory.

-40°C to +180°C

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email sales@bareiss.de

Opening hours:

Monday - Thursday: 07.00 - 16.00 Uhr

Friday: 07.00 - 12.00 Uhr

The digiChamber temperature chamber from Bareiss is the perfect solution to analyze the hardness changes at different temperature ranges. Through collaboration with the renowned provider of temperature solutions "Vötsch Technik", you get temprature simulations with the best accuracy. Maximize your testing capabilities and capacities with our computer-controlled, serial temperature chamber for polymer hardness testing, with a temperature range from -40°C to +180°C. The corresponding hardness tester digi test II is mounted externally to avoid temperature-related measuring faults.

With the rotating table for sample positioning, hardness testing can be automated and conducted in series at freely definable measuring points on each sample. Alternatively, you can align the molded parts individually and manually through the opening of the chamber on the side.

With the "digiCenter" software, you can control temperature levels, conditioning time, and the number of measuring points, as well as manage the determined values in a database. For the display of the temperature-related hardness values, the program offers both graphics and value tables.

Best Quality

High-quality Bareiss hardness tester combined with high-quality temperature chamber from "Vötsch Technik" for best test results.

Hardness testing under realistic operating conditions

Test how temperature influence has an impact on the hardness of your material and simulate real conditions from -40°C to +180°C.

Simple and intuitive operation

In the intuitive operable "digiCenter" software, you can create test plans for different materials or requirements and save them as templates.

High flexibility of the testing procedure

The digiChamber offers flexible options for defining measuring points on each individual sample and for serial measurement.

Other features

Scope of delivery according to packing list

Temperature chamber digiChamber

Measuring device Shore A or IRHD N

Software "digiCenter"

Operating manual

Measuring device

Shore A or IRHD N

Reference elastomer blocks

with DAkkS accredited calibration certificate

DAkkS accredited calibration certificate

We have experience.

We have been active in the field of measurement technology since 1954 - now in the third generation.

We stay true to ourselves.

All of our products are developed and manufactured in Germany.

We are accredited.

Our DAkkS accredited calibration laboratory is certified according to DIN EN/IEC 17025.

We are committed.

We are a member of the DIN committee and set standards there in the area of hardness.

We have inventive talent.

We have developed and registered over 25 patents in the last few decades.

We distribute worldwide.

We and our partners are there for you anywhere in the world.