- Product Overview

- Industry sectors

- Accredited service

- ISO 17025 calibration

- Manufacturer & calibration laboratory

- Rental device & contract measurement

- Seminars & training

- Support & infos

- Company

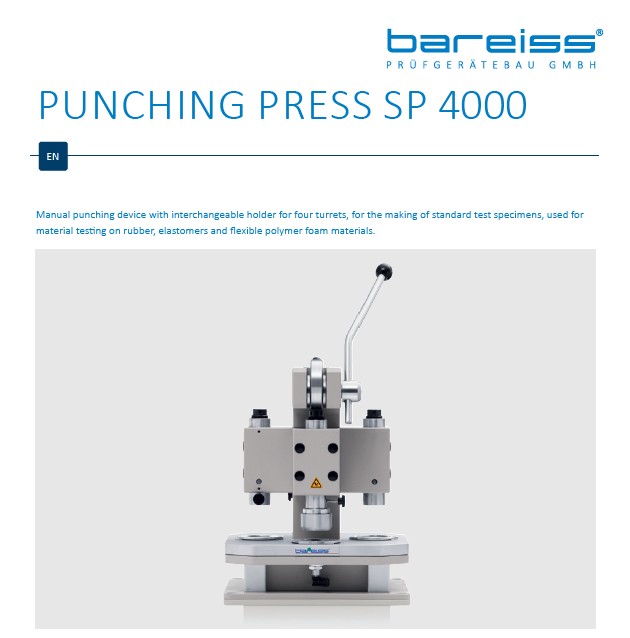

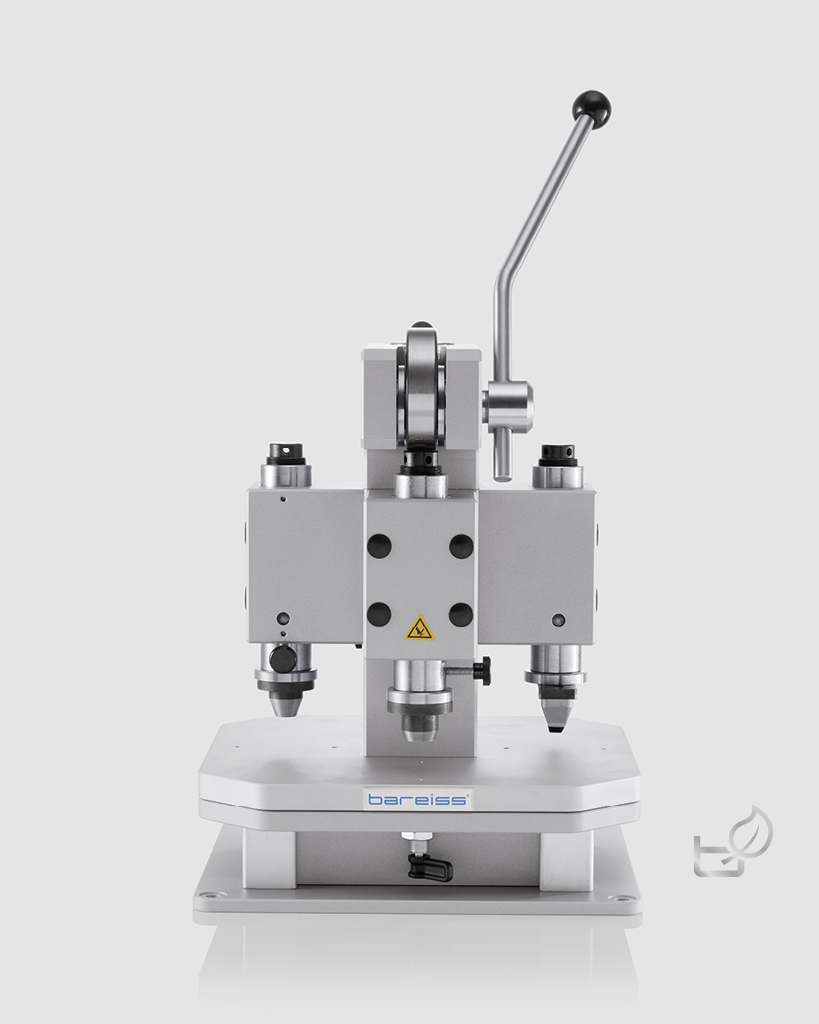

The manual Punching press SP 4000 II accommodates up to four punching devices simultaneously for the production of your standard test specimens from rubber and elastic polymer materials. This allows you to quickly switch between different sample geometries without having to exchange the tool beforehand.

Conventiently unlocked via lever, the punching devices along with the punching table can be rotated into the working position. The previously individually adjusted distance between the punching tool and the base, the punching depth, remains unchanged. The handy eccentric lever reduces the required punching force to a comfortable level, allowing for easy operation of the press. Each punching device includes an automatic ejector, which facilitates the removal of the punched samples from the tool. With the additionally available centering rings, the SP 4000 is also ideally suited for the production of ring-shaped samples.

Other features

Punching press SP 4000 II

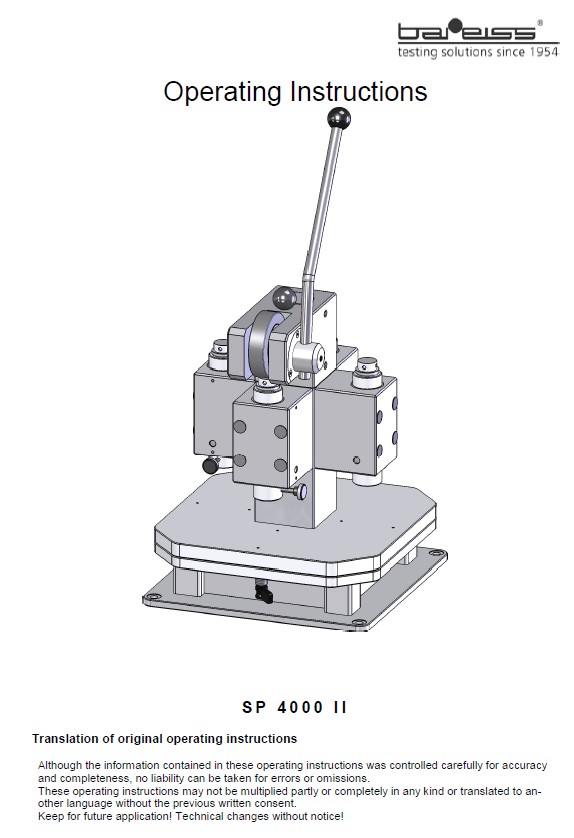

Operating manual

For the punching press SP 4000 II, punching devices for samples from flat materials are manufactured according to all standards upon customer request. Customized special shapes according to drawings are also possible. Please inquire with us.

Examples of standard test specimens:

Punching of up to 4 different standard test specimens for hardness testing

Punching device with holder and ejector

Centering rings

Punching support plate

Sheet material

None

Dim. W x H x D: min. 33 x 33 x 64 cm

max. 40 x 65 x 43 cm

Weight: 40,00 kg

Press cut: Pressure: 5 kN

Depth: max. 24 mm

Throat depth: max. 60 mm

Supporting table: max. 120 x 330 mm

None

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

None

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

Manual punching device with interchangeable brackets for four revolvers for the production of standard test specimens for material testing on rubber, elastomers, and flexible polymer foams.

![]() Bareiss Silverline 25

Bareiss Silverline 25

New colors, lived responsibility – coatings for a better future

The transition to the new coating will begin mid-year. During the transition period, some devices may still be delivered with previous coating. We kindly ask for your understanding that the new coating cannot be guaranteed.

Sheet material

None

Dim. W x H x D: min. 33 x 33 x 64 cm

max. 40 x 65 x 43 cm

Weight: 40,00 kg

Press cut: Pressure: 5 kN

Depth: max. 24 mm

Throat depth: max. 60 mm

Supporting table: max. 120 x 330 mm

None

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

None

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email sales@bareiss.de

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

The manual Punching press SP 4000 II accommodates up to four punching devices simultaneously for the production of your standard test specimens from rubber and elastic polymer materials. This allows you to quickly switch between different sample geometries without having to exchange the tool beforehand.

Conventiently unlocked via lever, the punching devices along with the punching table can be rotated into the working position. The previously individually adjusted distance between the punching tool and the base, the punching depth, remains unchanged. The handy eccentric lever reduces the required punching force to a comfortable level, allowing for easy operation of the press. Each punching device includes an automatic ejector, which facilitates the removal of the punched samples from the tool. With the additionally available centering rings, the SP 4000 is also ideally suited for the production of ring-shaped samples.

Other features

Punching press SP 4000 II

Operating manual

Punching device with holder and ejector

Centering rings

Punching support plate