- Product Overview

- Industry sectors

- Accredited service

- ISO 17025 calibration

- Manufacturer & calibration laboratory

- Rental device & contract measurement

- Seminars & training

- Support & infos

- Company

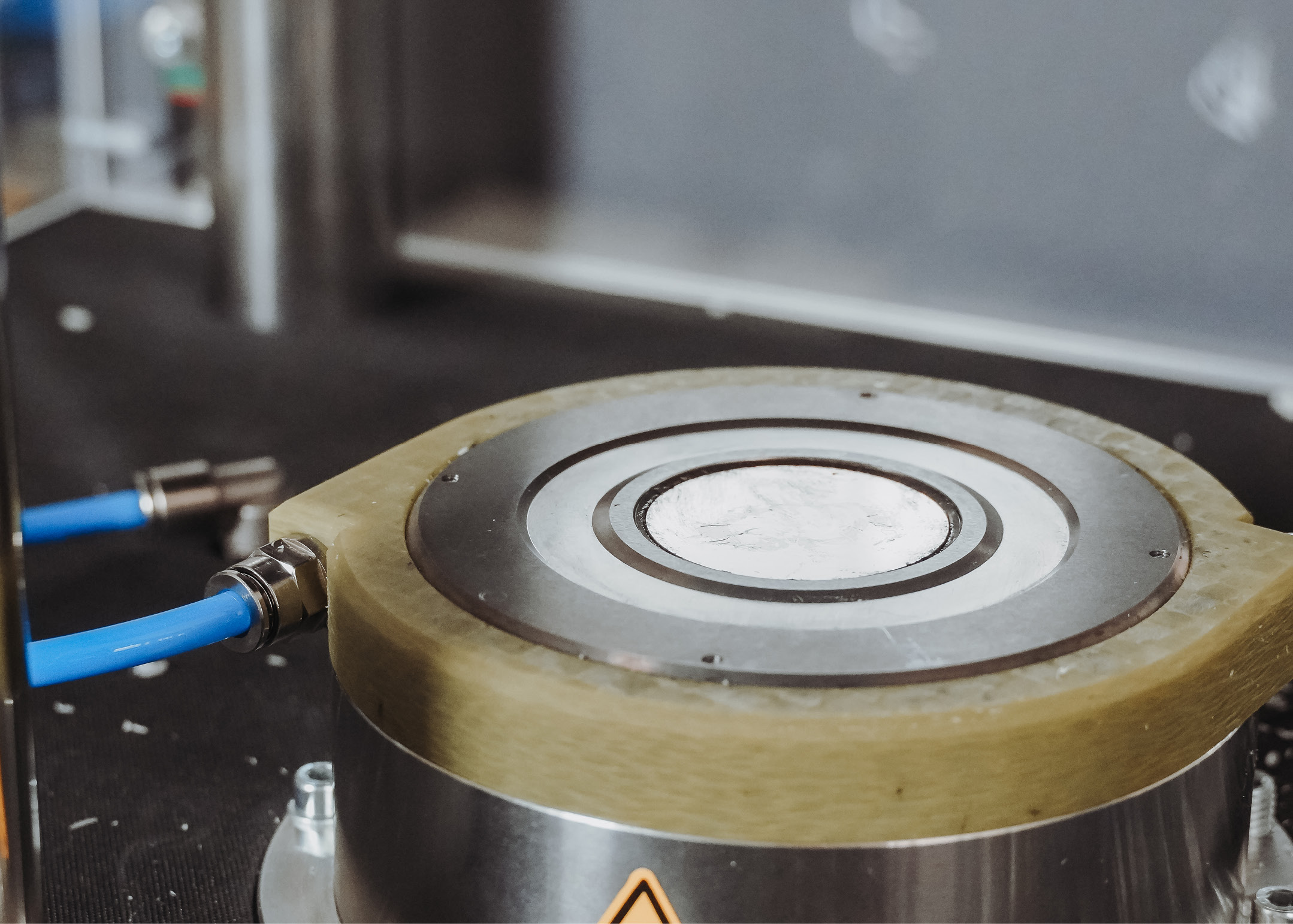

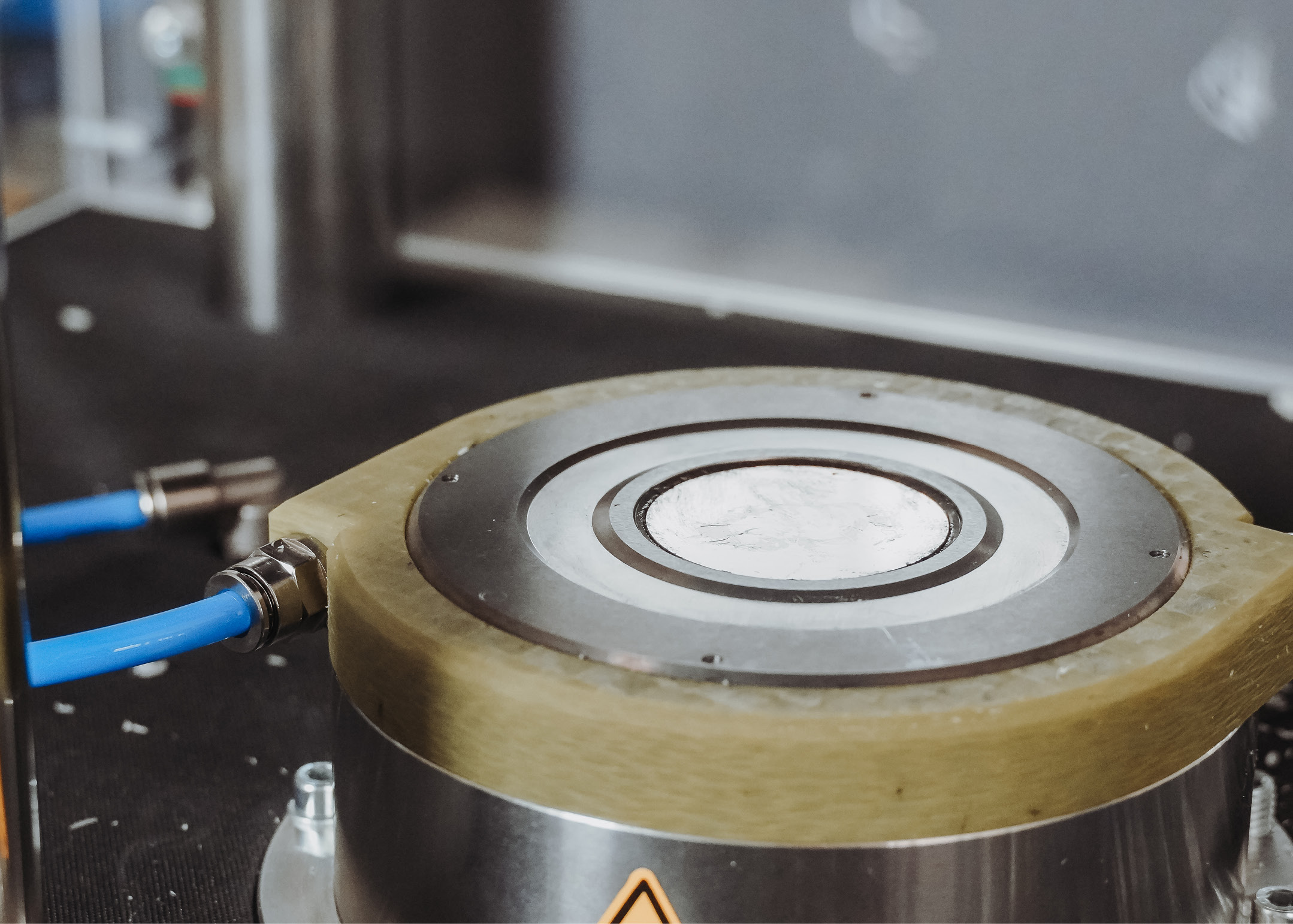

The RPA ultra is an advanced instrument for analyzing elastomer viscoelastic properties, surpassing standard Rubber Process Analyzers. The instrument also has afully rotational lower die, mirroring the dynamic conditions of rubber processing and manufacturing. This feature is critical for stimulating real-world scenarios, allowing for the precise characterization of elastomer behavior during processes such as molding, extrusion, and curing.

The user-friendly BareissOne software ensures seamless data management and interpretation, empowering researchers to optimize formulations, improve quality control, and accelerate product development across rubber and polymer industries.

Fully rotational lower die for process relevant simulation

Experience testing that mirrors reality. Designed for extrusion-relevant shear rates, the RPA ultra simulates actual processing conditions, bridging the gap between lab results and production outcomes.

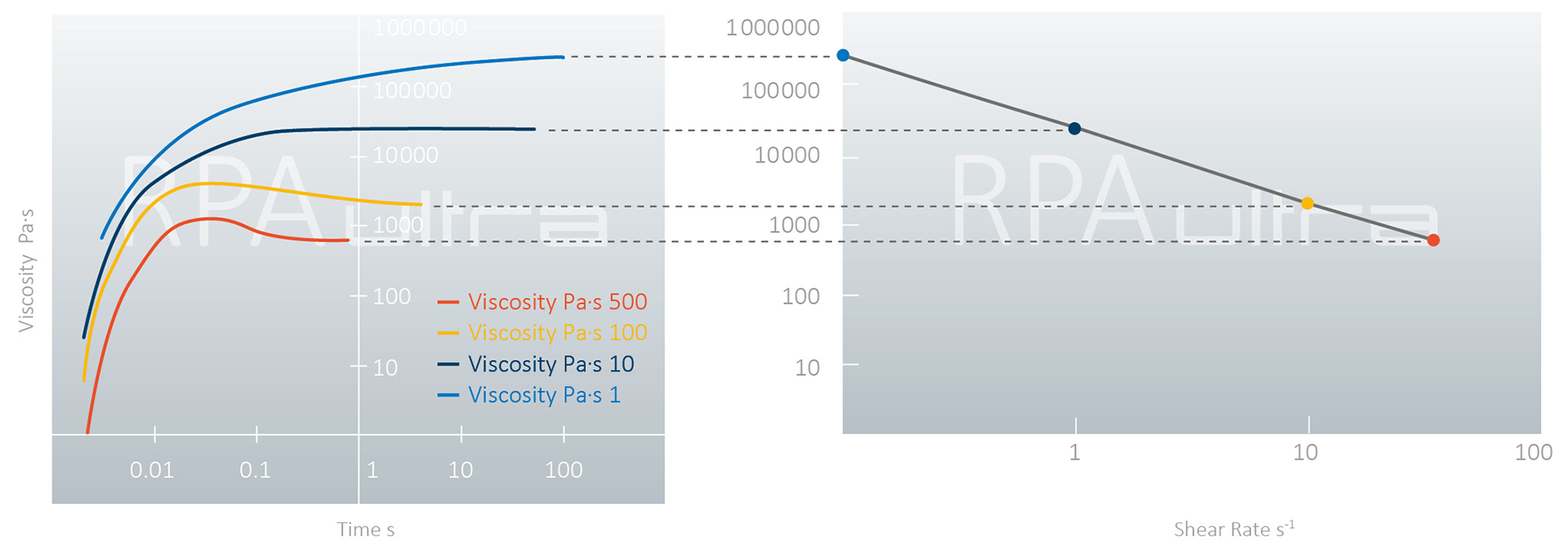

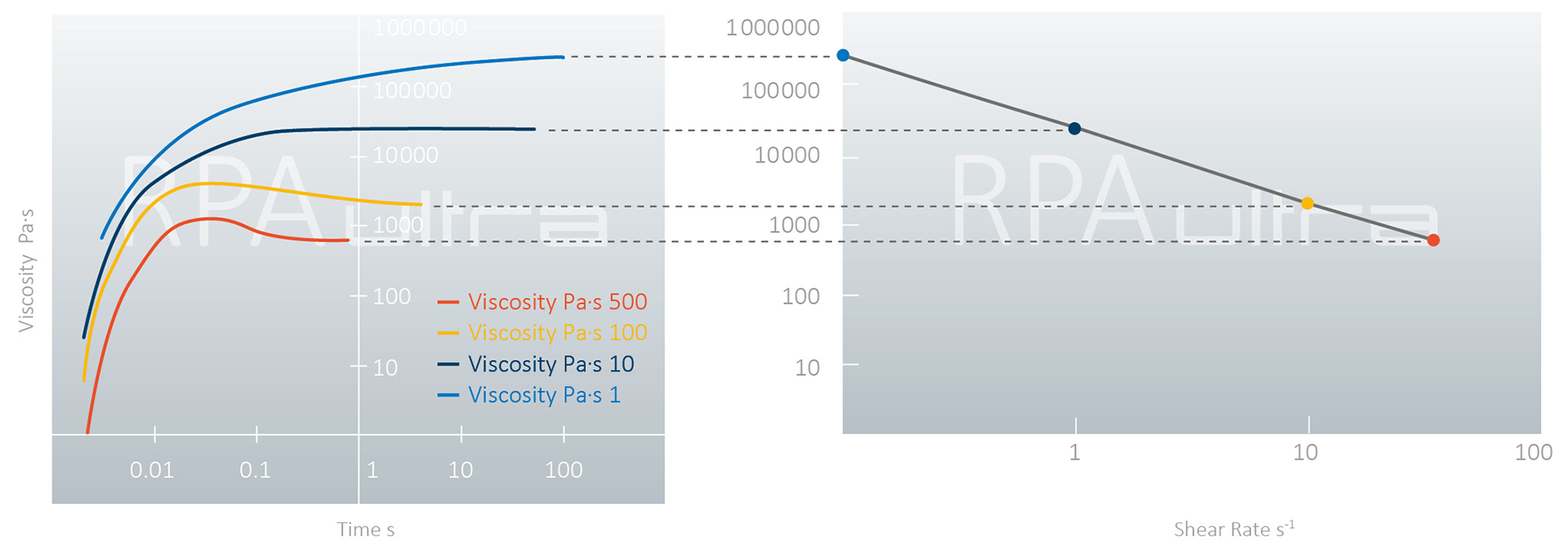

Steady Shear Viscosity

To better understand the manufacturing process of an unvulcanized rubber compound, the steady shear viscosity is one of the most important properties, especially crucial for determining the process parameters for extrusion and injection molding purposes.

The RPA ultra’s rotating lower die with unlimited strain thus provides the user with a dual test mode: dynamic and steady shear.

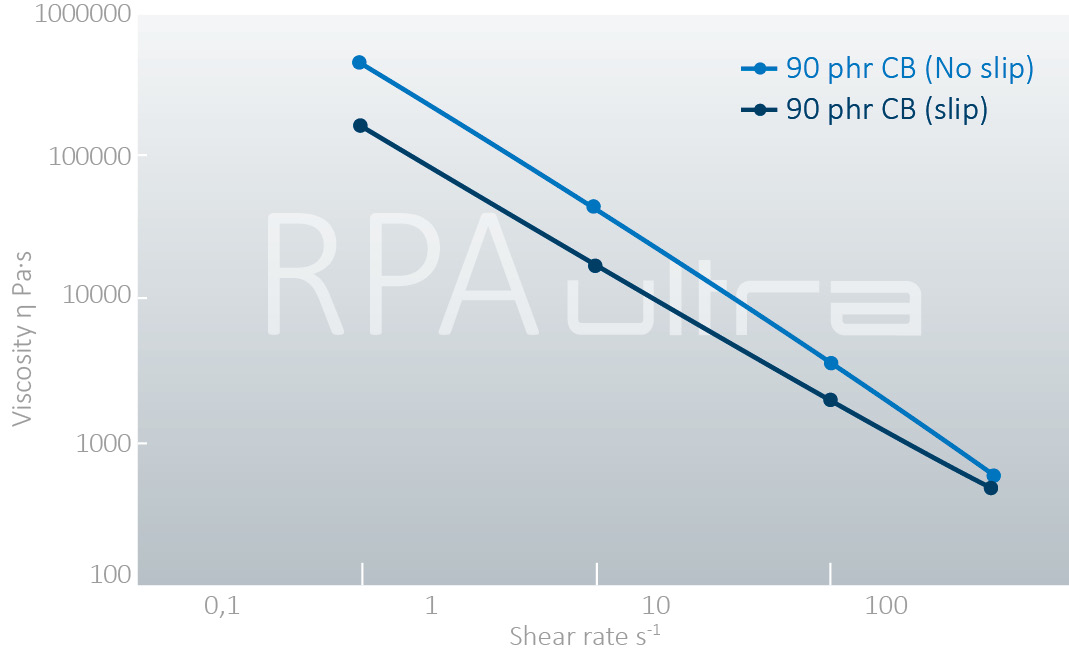

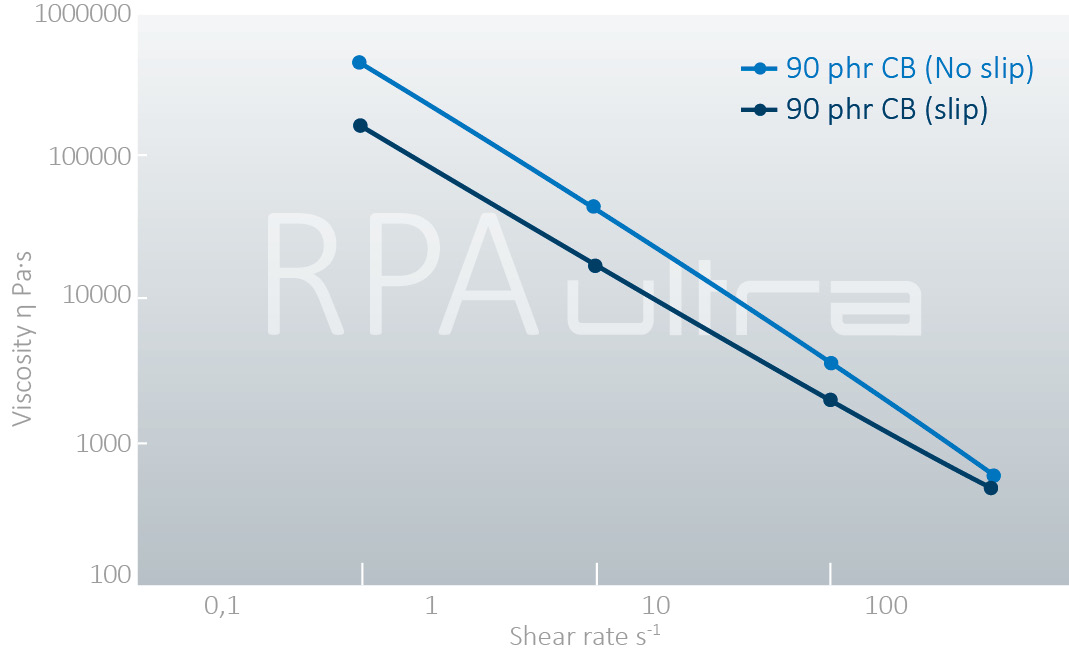

Wall Slip

A significant challenge in the processing of rubber compounds is the issue of Wall Slip.

This is a rheological phenomenon where slippage occurs, for example, between the extruder wall and the flowing material.

We offer an optional solution where the upper die is replaced by a defined polished die set. In combination with a programmable internal pressure, this allows Wall Slip experiments to be carried out.

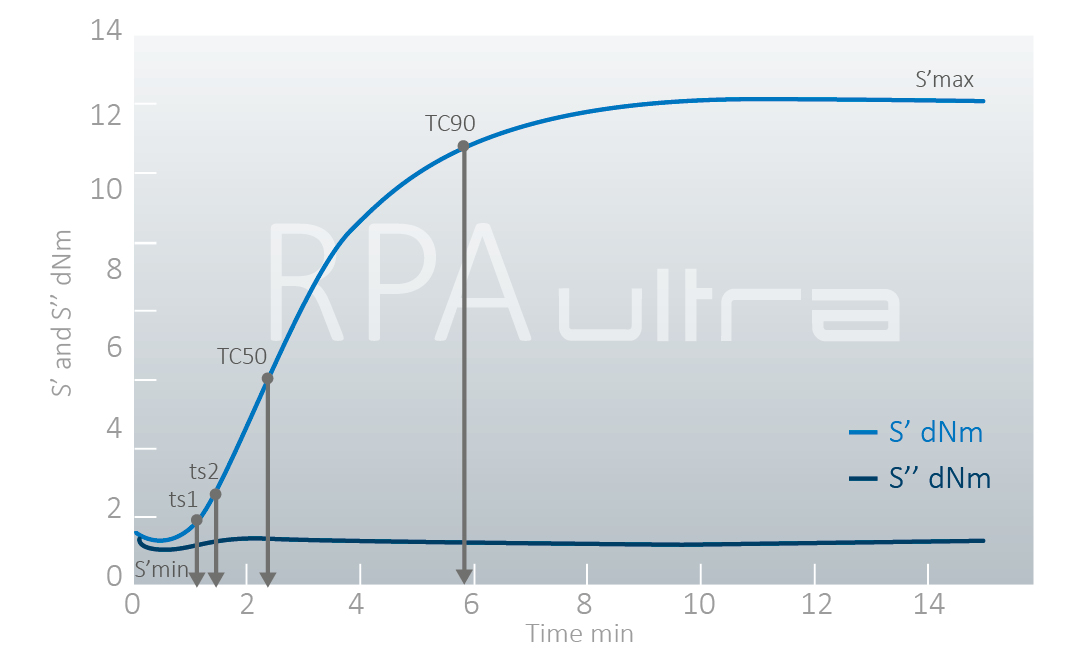

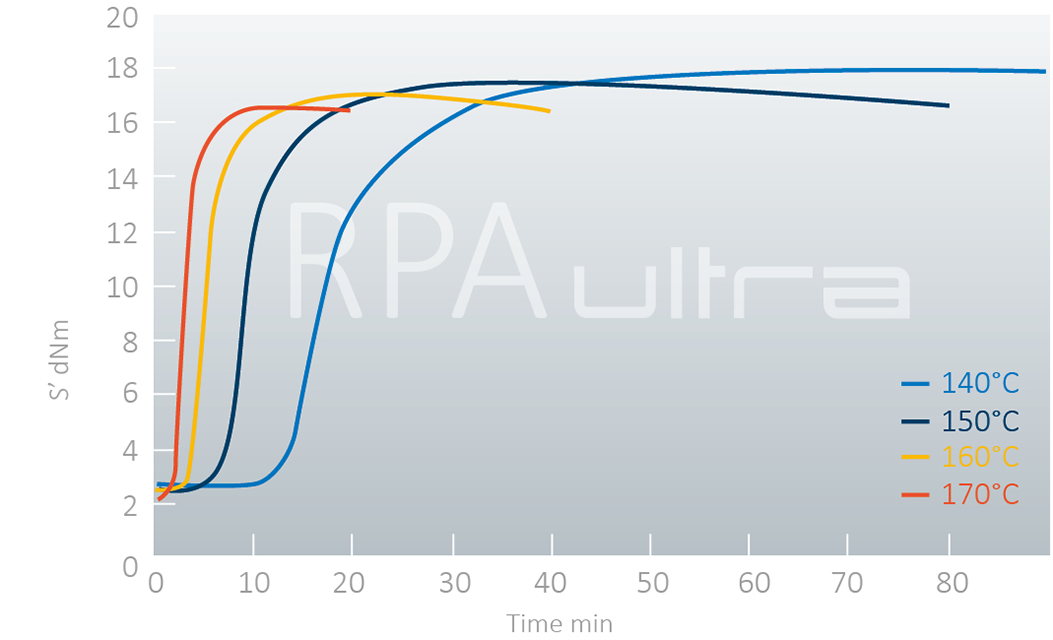

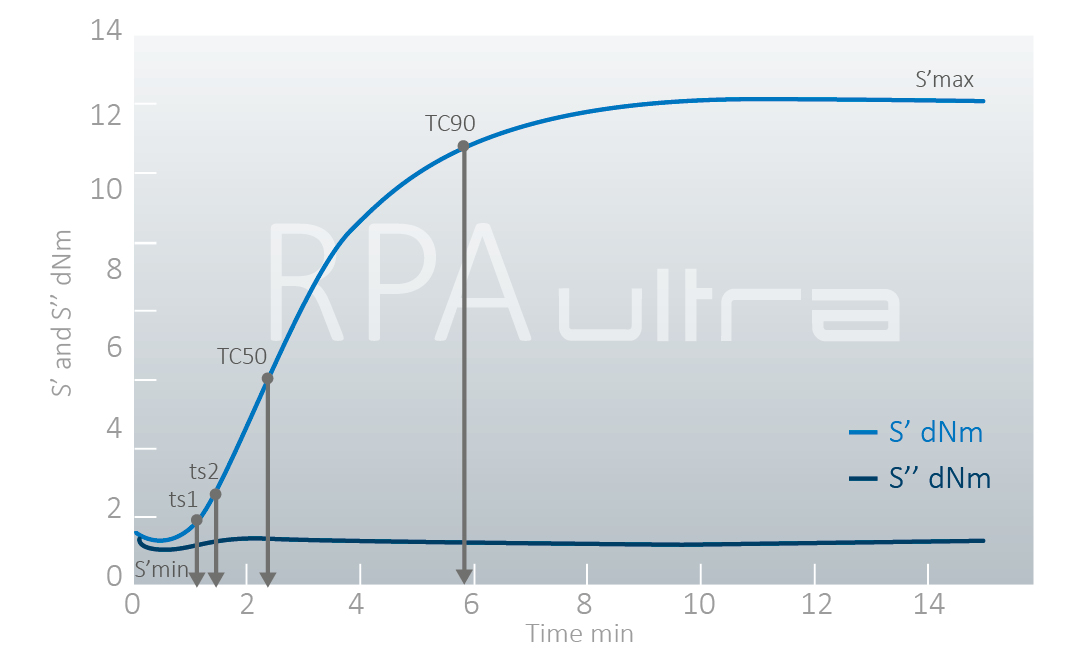

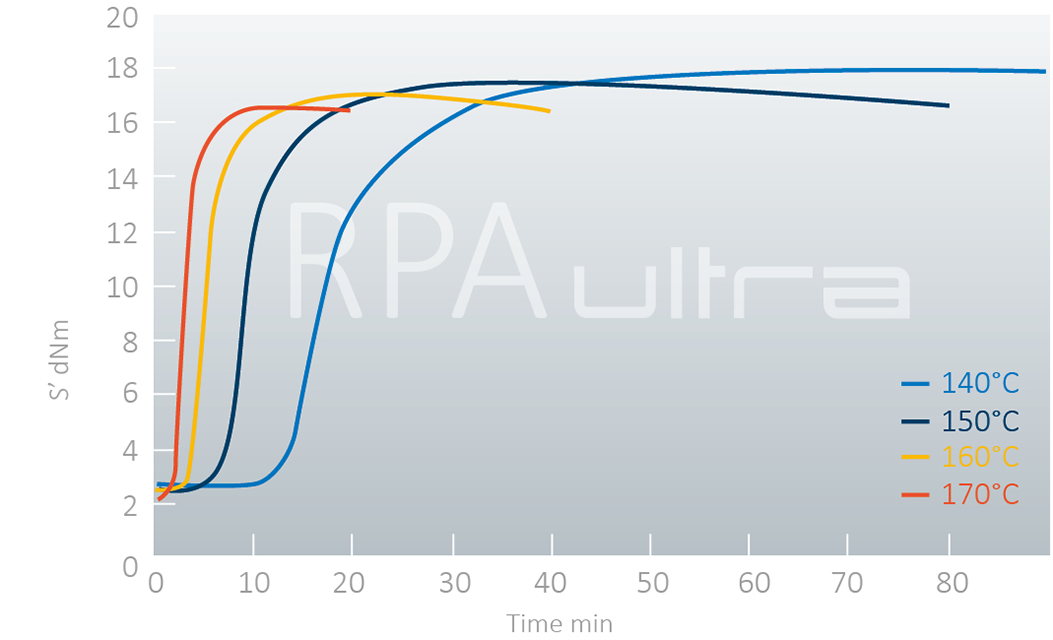

Isothermal Test

One of the most common and important tests performed on rubber compounds are the isothermal cure tests.

All important test parameters such as maximum and minimum torque, TC values, reaction time and rate, etc. are determined and made available to the user in tabular and/or graphical form for further analysis in the BareissOne software.

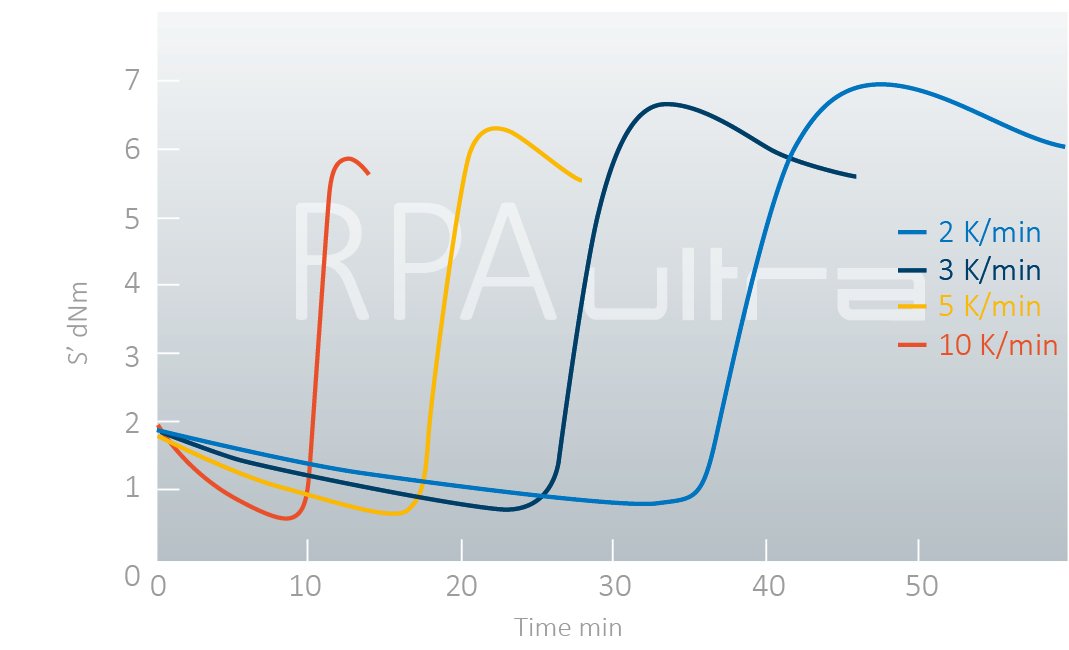

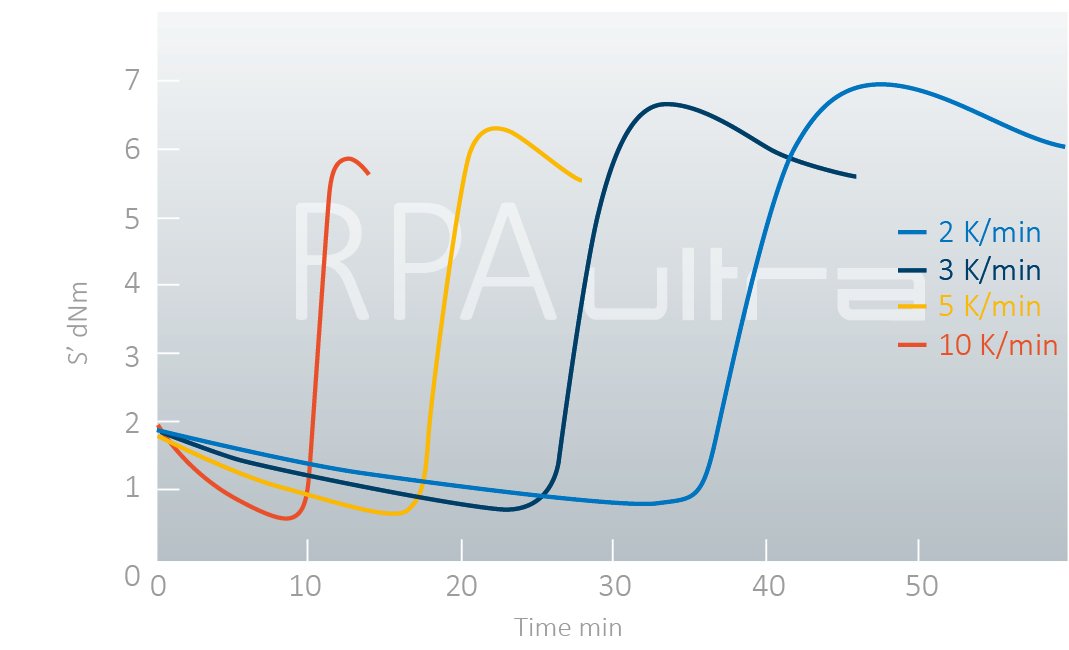

Non-Isothermal Test

In order to evaluate the behavior of a sample over a wide temperature range, non-isothermal measurements (temperature sweep) are typically performed at different heating rates.

This measurement at different heating rates also paves the way for non-isothermal kinetic calculations – a module that is also integrated into the BareissOne software.

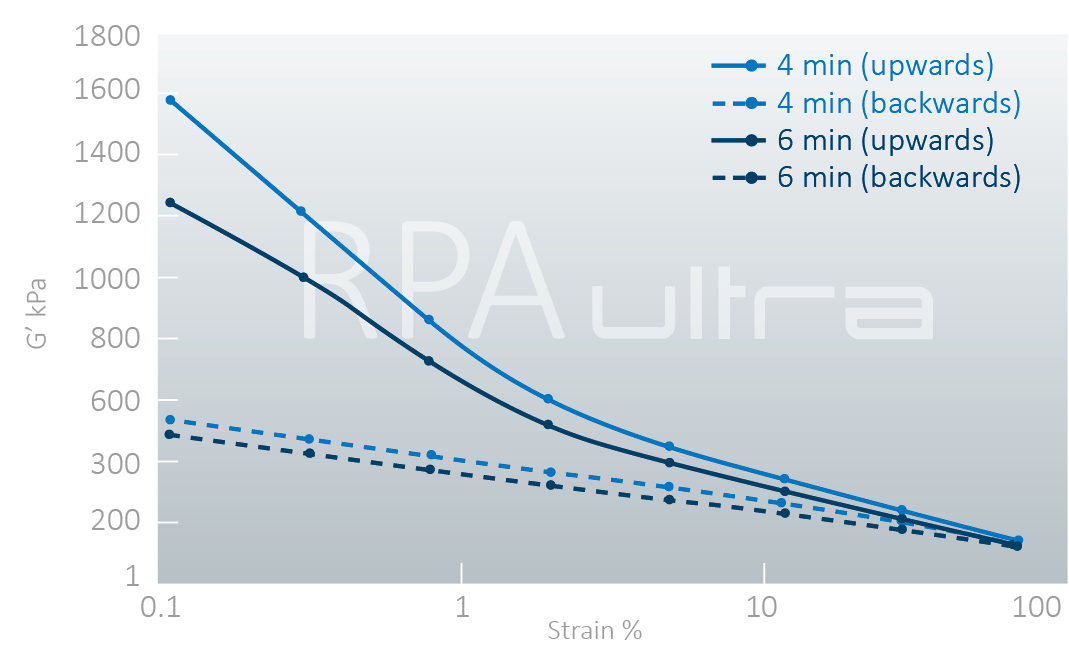

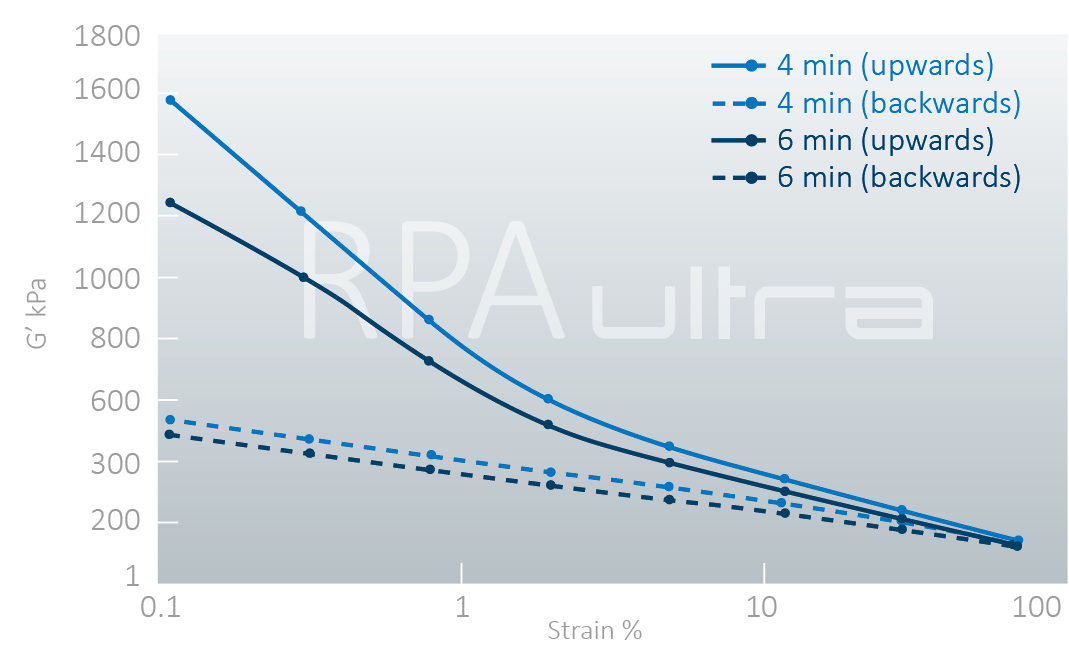

Large Amplitude Oscillatory Shear (LAOS)

LAOS is essentially a strain sweep performed at relatively large amplitudes to investigate and evaluate the nonlinear viscoelastic behavior of a sample.

The nonlinear behavior of a material is based on its polymer architecture > linear or branched polymer.

The LAOS results are also used for FT- Rheology. The calculation of the LCB index (Long Chain Branching) or the Q-parameter is performed using the harmonic spectrum from Fourier analysis (FFT).

Kinetics

From an isothermal test, values such as incubation time, reaction order and conversion rate constant can be determined for each temperature. The calculation is according to the

DIN 53529 standard. With the help of the incubation time and the conversion rate constant at at least 3 different temperatures, the activation energies of the incubation and the conversion can also be determined. These are essential parameters for the computation of the heating time for the test specimen and also finds its use in production line.

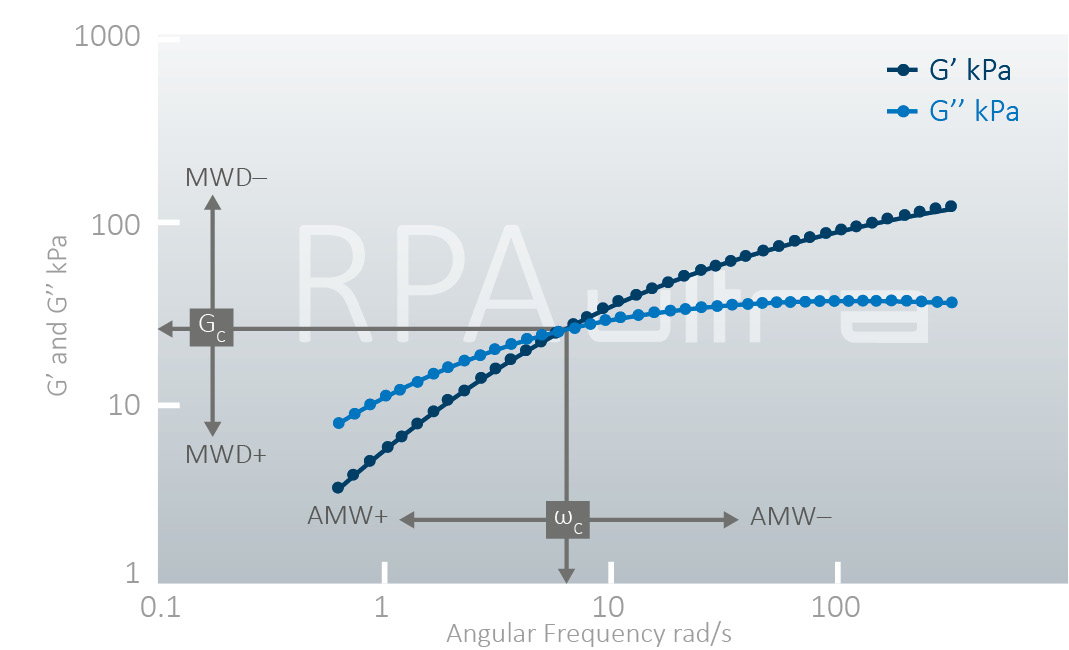

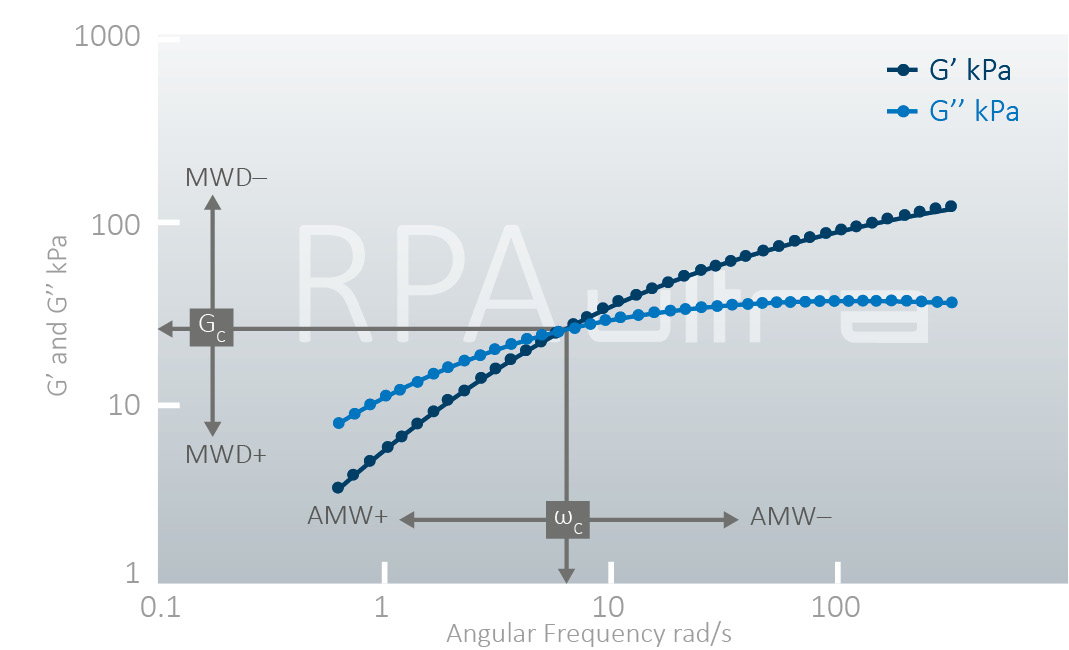

Frequency Sweep

By characterizing a sample over a wide range of frequencies, the user obtains a comprehensive overview of the viscoelastic behavior as well as the molecular structure (molecular weight and molecular weight distribution).

Viscoelastic properties such as complex modulus, elastic modulus, loss modulus, complex viscosity, phase angle, etc. are calculated at each frequency as a result of the frequency-dependent behavior of the sample.

Strain Sweep

Measuring a specimen over a wide strain range shows the strain-dependent behavior, e.g., the linear viscoelastic range (LVE) up to Large Amplitude Oscillatory Shear (LAOS).

The Payne test, which is performed at small strain amplitudes to investigate the (filler/polymer) filler networks, reveals information about the filler content and the filler dispersion levels.

Matrix test

In the frequency and strain sweeps described above, one parameter (frequency or strain) is held constant while the other parameter (frequency or strain) is changed over a range.

Matrix testing allows the user to change both parameters

– frequency and strain – during a sweep, making the test method more flexible and thus providing more information with a single measurement.

Starter kit (cleaning brush,

tweezer, die groove pick)

2x long life die seals

High sampling rate for improved Fourier Transform (FT) Rheology

With an astounding high-sampling rate captured per cycle, the RPA ultra doesn't just analyze - it dissects material behavior with surgical precision. This, in turn, improves Fourier Transform Rheology (FTR) by converting time-domain data into frequency-domain information for a comprehensive analysis of viscoelastic material properties.

Production-Level Insights with Wall-Slip Analysis

By replacing the standard upper test die with a polished die set that mirrors extruder wall surface roughness, our RPA enables precise simulation of actual production conditions. This wall-slip measurement capability allows researchers to investigate material behavior more accurately.

Compatible with BareissOne - the software platform for your measurement data

Intuitive software simplifies complex testing procedures, allowing researchers to focus on analysis rather than instrument operation. Streamline your workflow and increase productivity.

World's first floor standing model

Say goodbye to stationary limitations. As the world's first floor-standing model with built-in rollers, the RPA ultra brings flexibility to your fingertips. Effortlessly glide it across your lab or to different testing sites.

Other features

Pure polymers, polymer blends, uncured rubber compounds, in-situ compounds, thermoplastics, liquid silicone rubber (LSR), Thermoplastic Elastomers (TPE), recovered carbon black (rCB) compounds

Wallslip die set

Reference samples

with certificate (Butyl, HDPE)

Torque Standard

with calibration certificate

Sample volume for each test: 4.5cm³

Sample shape/form: rubber sheet pucks, powder, pellets, gel/paste

Max. heating rate: 1.33°C/s (80°C/min)

Temperature range: Ambient to 235°C

Measurements: 800 x 620 x 2000 mm

Weight: approx. 420 kg

Max. shear rate in rotation: 500 s-1

Max. shear rate in oscillation: 100 s-1

Die config.: Sealed die, biconical and plate-plate

Drive system: High-dynamic servo motor, High-resolution measurement technology

Oscillation frequency: 0.001 to 100 Hz

Oscillation strain: +/- 0.001° to unlimited, +/- 0.014% to unlimited, > rotational

Measured data: Torque, temperature, frequency, strain; Optional: Normal force, die pressure

Die gap: 0.48 mm nominal

Sample volume: 4.5 cm3

Electrical: 400V/16A

Closing system: Soft closing to prevent foil rips and damage of test samples; optionally variable closing force.

Torque range: 0.001 to 250 dNm

Normal force / Pressure (opt.): up to 10 kN

Test modes: Isothermal, Non-Isothermal, Strain Sweep, Frequency Sweep, Steady Shear, Relaxation, LAOS, Matrix Test

Interface: Ethernet

Data points: Over 3500 data points available for each static subtest including S‘ Min, S‘ Max, TS 1, TS 2, TC 10, TC 30, TC 50, TC 90 Integrated, automatic reporting features for dynamic tests

Pneumatics: min. 6 Bar (11.5 kN) / 60 psi

Electrical connection:

400 V, 16 A

RCD integrated in the media column

Pneumatic connection:

A plug nipple with NW 7.2 is installed on the device side

On the customer side, a hose with a standard quick coupling NW 7.2 mm is required

Extraction connection:

The outer diameter of the extraction port is 100 mm

The extraction connection is located on the upper right side of the device

The customer-side extraction pipe can be attached to the connection using suitable means

DAkkS Accredited Service

Since 1996, Bareiss Prüfgerätebau GmbH has been recognized as a DAkkS-accredited calibration laboratory, standing for the highest quality and precision. Our calibrations comply with international standards according to DIN EN ISO/IEC 17025:2018, ensuring reliable and internationally comparable measurement results.

Take advantage of our service offerings:

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results. Benefit from our experience as a manufacturer and accredited calibration laboratory.

PC Hardware Requirements:

Windows 10 or higher

Minimum 16 GB RAM

Minimum 256 GB SSD

Dedicated network interface card with 1 Gbit/s

Patch cable between computer and device

Administrator rights

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email

Opening hours:

Monday - Thursday: 07.00 - 16.00 Uhr

Friday: 07.00 - 12.00 Uhr

A rotorless rubber rheometer to analyze the viscoelastic propertiesof elastomers and rubber compounds. It measures material behavior under various conditions, aiding in quality control, product development, and process optimization.

The RPA ultra is a comprehensive tool for analyzing the viscoelastic properties of elastomers, performing all the functions of a standard Rubber Process Analyzer. Its unique feature - a rotating lower die - enables more accurate simulation of real-world processing conditions, delivering greater precision and deeper insights into material behavior.

Sample volume for each test: 4.5cm³

Sample shape/form: rubber sheet pucks, powder, pellets, gel/paste

Max. heating rate: 1.33°C/s (80°C/min)

Temperature range: Ambient to 235°C

Measurements: 800 x 620 x 2000 mm

Weight: approx. 420 kg

Max. shear rate in rotation: 500 s-1

Max. shear rate in oscillation: 100 s-1

Die config.: Sealed die, biconical and plate-plate

Drive system: High-dynamic servo motor, High-resolution measurement technology

Oscillation frequency: 0.001 to 100 Hz

Oscillation strain: +/- 0.001° to unlimited, +/- 0.014% to unlimited, > rotational

Measured data: Torque, temperature, frequency, strain; Optional: Normal force, die pressure

Die gap: 0.48 mm nominal

Sample volume: 4.5 cm3

Electrical: 400V/16A

Closing system: Soft closing to prevent foil rips and damage of test samples; optionally variable closing force.

Torque range: 0.001 to 250 dNm

Normal force / Pressure (opt.): up to 10 kN

Test modes: Isothermal, Non-Isothermal, Strain Sweep, Frequency Sweep, Steady Shear, Relaxation, LAOS, Matrix Test

Interface: Ethernet

Data points: Over 3500 data points available for each static subtest including S‘ Min, S‘ Max, TS 1, TS 2, TC 10, TC 30, TC 50, TC 90 Integrated, automatic reporting features for dynamic tests

Pneumatics: min. 6 Bar (11.5 kN) / 60 psi

Electrical connection:

400 V, 16 A

RCD integrated in the media column

Pneumatic connection:

A plug nipple with NW 7.2 is installed on the device side

On the customer side, a hose with a standard quick coupling NW 7.2 mm is required

Extraction connection:

The outer diameter of the extraction port is 100 mm

The extraction connection is located on the upper right side of the device

The customer-side extraction pipe can be attached to the connection using suitable means

DAkkS Accredited Service

Since 1996, Bareiss Prüfgerätebau GmbH has been recognized as a DAkkS-accredited calibration laboratory, standing for the highest quality and precision. Our calibrations comply with international standards according to DIN EN ISO/IEC 17025:2018, ensuring reliable and internationally comparable measurement results.

Take advantage of our service offerings:

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results. Benefit from our experience as a manufacturer and accredited calibration laboratory.

PC Hardware Requirements:

Windows 10 or higher

Minimum 16 GB RAM

Minimum 256 GB SSD

Dedicated network interface card with 1 Gbit/s

Patch cable between computer and device

Administrator rights

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email sales@bareiss.de

Opening hours:

Monday - Thursday: 07.00 - 16.00 Uhr

Friday: 07.00 - 12.00 Uhr

The RPA ultra is an advanced instrument for analyzing elastomer viscoelastic properties, surpassing standard Rubber Process Analyzers. The instrument also has afully rotational lower die, mirroring the dynamic conditions of rubber processing and manufacturing. This feature is critical for stimulating real-world scenarios, allowing for the precise characterization of elastomer behavior during processes such as molding, extrusion, and curing.

The user-friendly BareissOne software ensures seamless data management and interpretation, empowering researchers to optimize formulations, improve quality control, and accelerate product development across rubber and polymer industries.

Fully rotational lower die for process relevant simulation

Experience testing that mirrors reality. Designed for extrusion-relevant shear rates, the RPA ultra simulates actual processing conditions, bridging the gap between lab results and production outcomes.

High sampling rate for improved Fourier Transform (FT) Rheology

With an astounding high-sampling rate captured per cycle, the RPA ultra doesn't just analyze - it dissects material behavior with surgical precision. This, in turn, improves Fourier Transform Rheology (FTR) by converting time-domain data into frequency-domain information for a comprehensive analysis of viscoelastic material properties.

Production-Level Insights with Wall-Slip Analysis

By replacing the standard upper test die with a polished die set that mirrors extruder wall surface roughness, our RPA enables precise simulation of actual production conditions. This wall-slip measurement capability allows researchers to investigate material behavior more accurately.

Compatible with BareissOne - the software platform for your measurement data

Intuitive software simplifies complex testing procedures, allowing researchers to focus on analysis rather than instrument operation. Streamline your workflow and increase productivity.

World's first floor standing model

Say goodbye to stationary limitations. As the world's first floor-standing model with built-in rollers, the RPA ultra brings flexibility to your fingertips. Effortlessly glide it across your lab or to different testing sites.

Other features

Steady Shear Viscosity

To better understand the manufacturing process of an unvulcanized rubber compound, the steady shear viscosity is one of the most important properties, especially crucial for determining the process parameters for extrusion and injection molding purposes.

The RPA ultra’s rotating lower die with unlimited strain thus provides the user with a dual test mode: dynamic and steady shear.

Wall Slip

A significant challenge in the processing of rubber compounds is the issue of Wall Slip.

This is a rheological phenomenon where slippage occurs, for example, between the extruder wall and the flowing material.

We offer an optional solution where the upper die is replaced by a defined polished die set. In combination with a programmable internal pressure, this allows Wall Slip experiments to be carried out.

Isothermal Test

One of the most common and important tests performed on rubber compounds are the isothermal cure tests.

All important test parameters such as maximum and minimum torque, TC values, reaction time and rate, etc. are determined and made available to the user in tabular and/or graphical form for further analysis in the BareissOne software.

Non-Isothermal Test

In order to evaluate the behavior of a sample over a wide temperature range, non-isothermal measurements (temperature sweep) are typically performed at different heating rates.

This measurement at different heating rates also paves the way for non-isothermal kinetic calculations – a module that is also integrated into the BareissOne software.

Large Amplitude Oscillatory Shear (LAOS)

LAOS is essentially a strain sweep performed at relatively large amplitudes to investigate and evaluate the nonlinear viscoelastic behavior of a sample.

The nonlinear behavior of a material is based on its polymer architecture > linear or branched polymer.

The LAOS results are also used for FT- Rheology. The calculation of the LCB index (Long Chain Branching) or the Q-parameter is performed using the harmonic spectrum from Fourier analysis (FFT).

Kinetics

From an isothermal test, values such as incubation time, reaction order and conversion rate constant can be determined for each temperature. The calculation is according to the

DIN 53529 standard. With the help of the incubation time and the conversion rate constant at at least 3 different temperatures, the activation energies of the incubation and the conversion can also be determined. These are essential parameters for the computation of the heating time for the test specimen and also finds its use in production line.

Frequency Sweep

By characterizing a sample over a wide range of frequencies, the user obtains a comprehensive overview of the viscoelastic behavior as well as the molecular structure (molecular weight and molecular weight distribution).

Viscoelastic properties such as complex modulus, elastic modulus, loss modulus, complex viscosity, phase angle, etc. are calculated at each frequency as a result of the frequency-dependent behavior of the sample.

Strain Sweep

Measuring a specimen over a wide strain range shows the strain-dependent behavior, e.g., the linear viscoelastic range (LVE) up to Large Amplitude Oscillatory Shear (LAOS).

The Payne test, which is performed at small strain amplitudes to investigate the (filler/polymer) filler networks, reveals information about the filler content and the filler dispersion levels.

Matrix test

In the frequency and strain sweeps described above, one parameter (frequency or strain) is held constant while the other parameter (frequency or strain) is changed over a range.

Matrix testing allows the user to change both parameters

– frequency and strain – during a sweep, making the test method more flexible and thus providing more information with a single measurement.

Starter kit (cleaning brush,

tweezer, die groove pick)

2x long life die seals

Wallslip die set

Reference samples

with certificate (Butyl, HDPE)

Torque Standard

with calibration certificate