- Product Overview

- Industry sectors

- Accredited service

- ISO 17025 calibration

- Manufacturer & calibration laboratory

- Rental device & contract measurement

- Seminars & training

- Support & infos

- Company

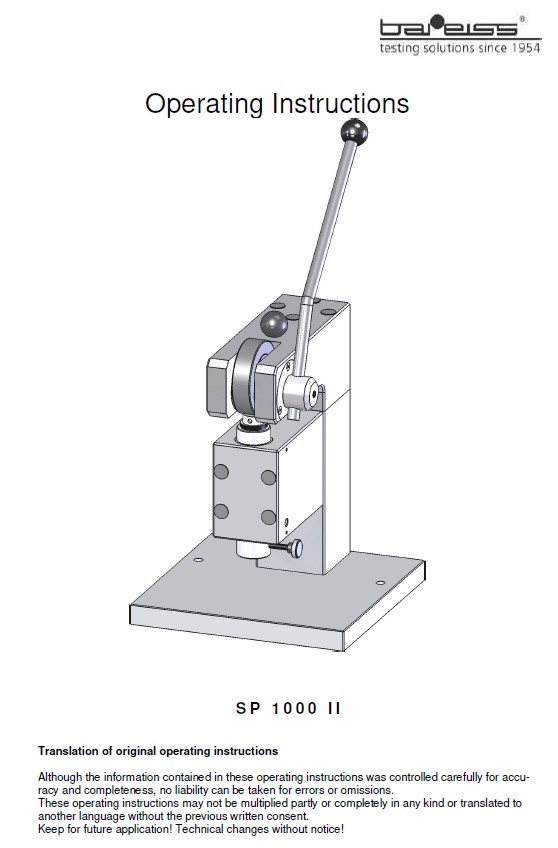

With the single Punching press SP 1000 II, you can punch standard test specimens from rubber, elastomers, or flexible polymer foams in a short time and with minimal effort.

The handy eccentric lever reduces the rewuireed force during the puncing process to a comfortable level, allowing for easy operation of the press. With just one knurled screw, the punching devices can be easily changed at any time. Numerous punching tools are availablefor the various sample geometries according to standard. The height of the plunger can be precisely adjusted to the thickness of the material samples. After the punching process, the integrated ejector in the punching device automatically releases the samples, facilitating their removal.

Other features

Punching press SP 1000 II

Punching support plate

For the punching press SP 1000 II, the punching devices for flat material samples are manufactured according to all standards upon customer request. Customized shapes based on drawings are also possible. Feel free to contact us for more information.

Examples of standard test specimens:

Press cut of standard test specimens for hardness testing

Punching device with holder and ejector

Punching support plate

Sheet material

None

Dim. W x H x D: min. 27 x 27 x 54 cm

max. 27 x 50 x 35 cm

Weight: 20,00 kg

Press cut: Pressure: 5 kN

Depth: max. 24 mm

Throat depth: max. 60 mm

Suppoting table: max. 175 x 270 mm

None

None

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

Manual punching device for the production of test specimens for standard test specimens used for material testing on rubber, elastomers, and flexible polymer foams.

![]() Bareiss Silverline 25

Bareiss Silverline 25

New colors, lived responsibility – coatings for a better future

The transition to the new coating will begin mid-year. During the transition period, some devices may still be delivered with previous coating. We kindly ask for your understanding that the new coating cannot be guaranteed.

Sheet material

None

Dim. W x H x D: min. 27 x 27 x 54 cm

max. 27 x 50 x 35 cm

Weight: 20,00 kg

Press cut: Pressure: 5 kN

Depth: max. 24 mm

Throat depth: max. 60 mm

Suppoting table: max. 175 x 270 mm

None

None

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email sales@bareiss.de

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

With the single Punching press SP 1000 II, you can punch standard test specimens from rubber, elastomers, or flexible polymer foams in a short time and with minimal effort.

The handy eccentric lever reduces the rewuireed force during the puncing process to a comfortable level, allowing for easy operation of the press. With just one knurled screw, the punching devices can be easily changed at any time. Numerous punching tools are availablefor the various sample geometries according to standard. The height of the plunger can be precisely adjusted to the thickness of the material samples. After the punching process, the integrated ejector in the punching device automatically releases the samples, facilitating their removal.

Other features

Punching press SP 1000 II

Punching support plate

Punching device with holder and ejector

Punching support plate