- Product Overview

- Industry sectors

- Accredited service

- ISO 17025 calibration

- Manufacturer & calibration laboratory

- Rental device & contract measurement

- Seminars & training

- Support & infos

- Company

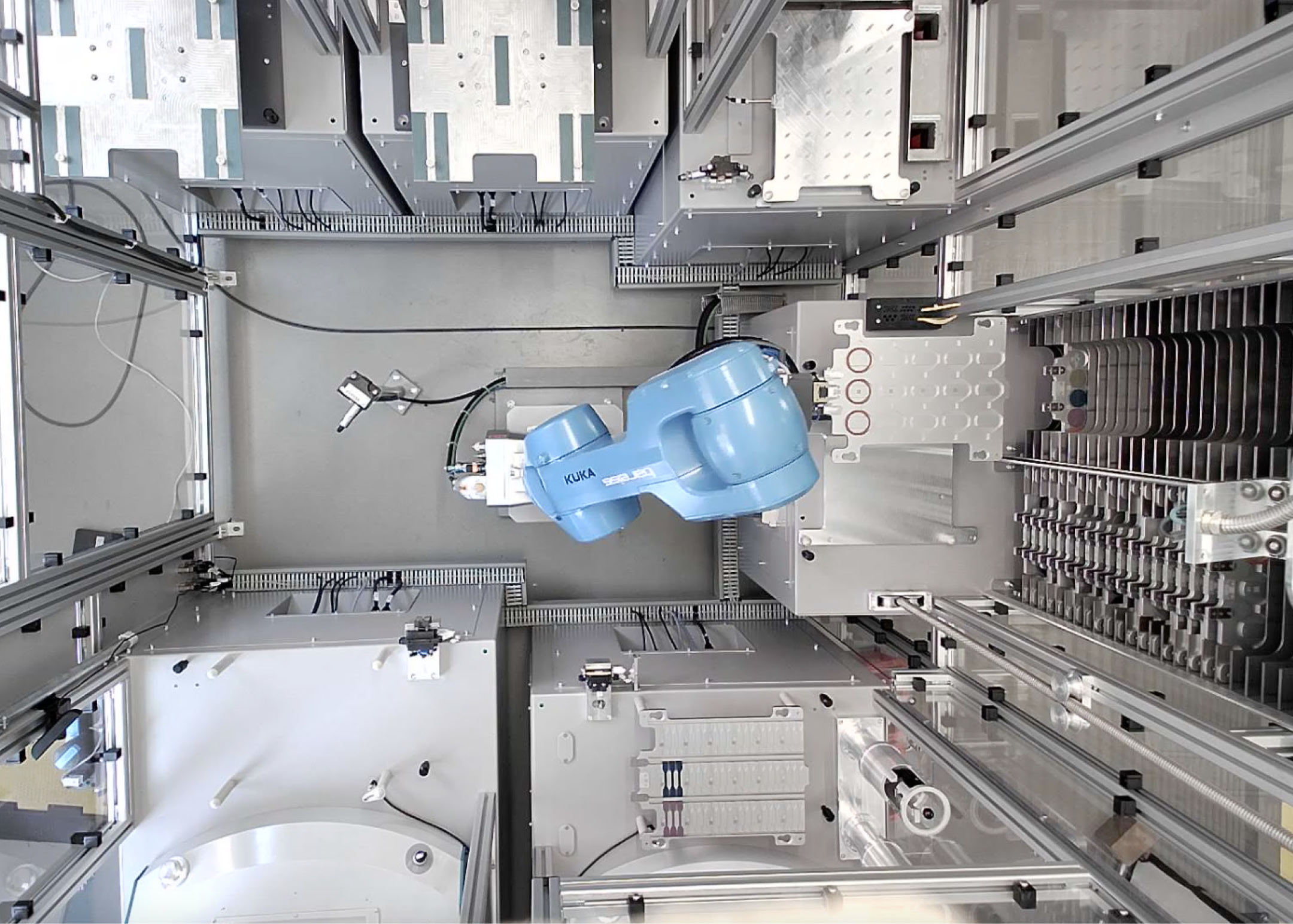

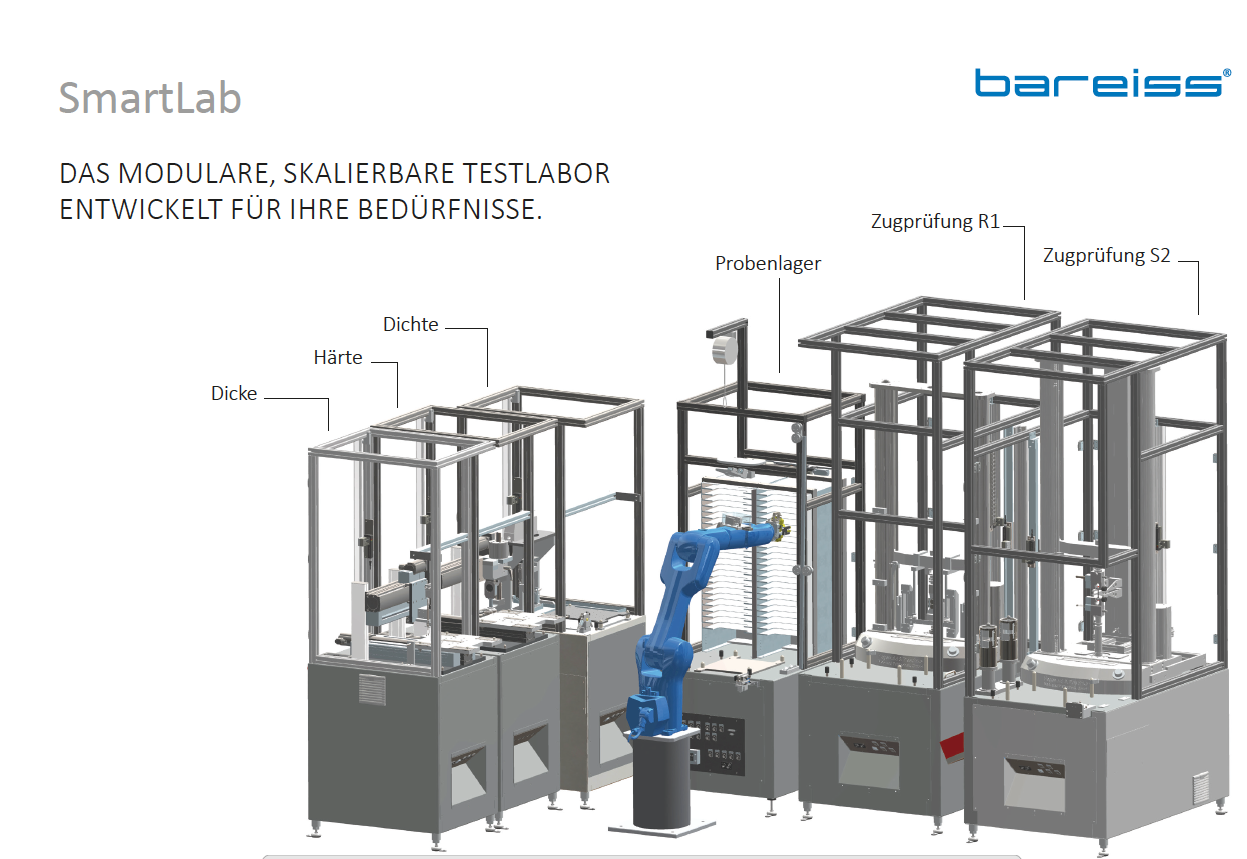

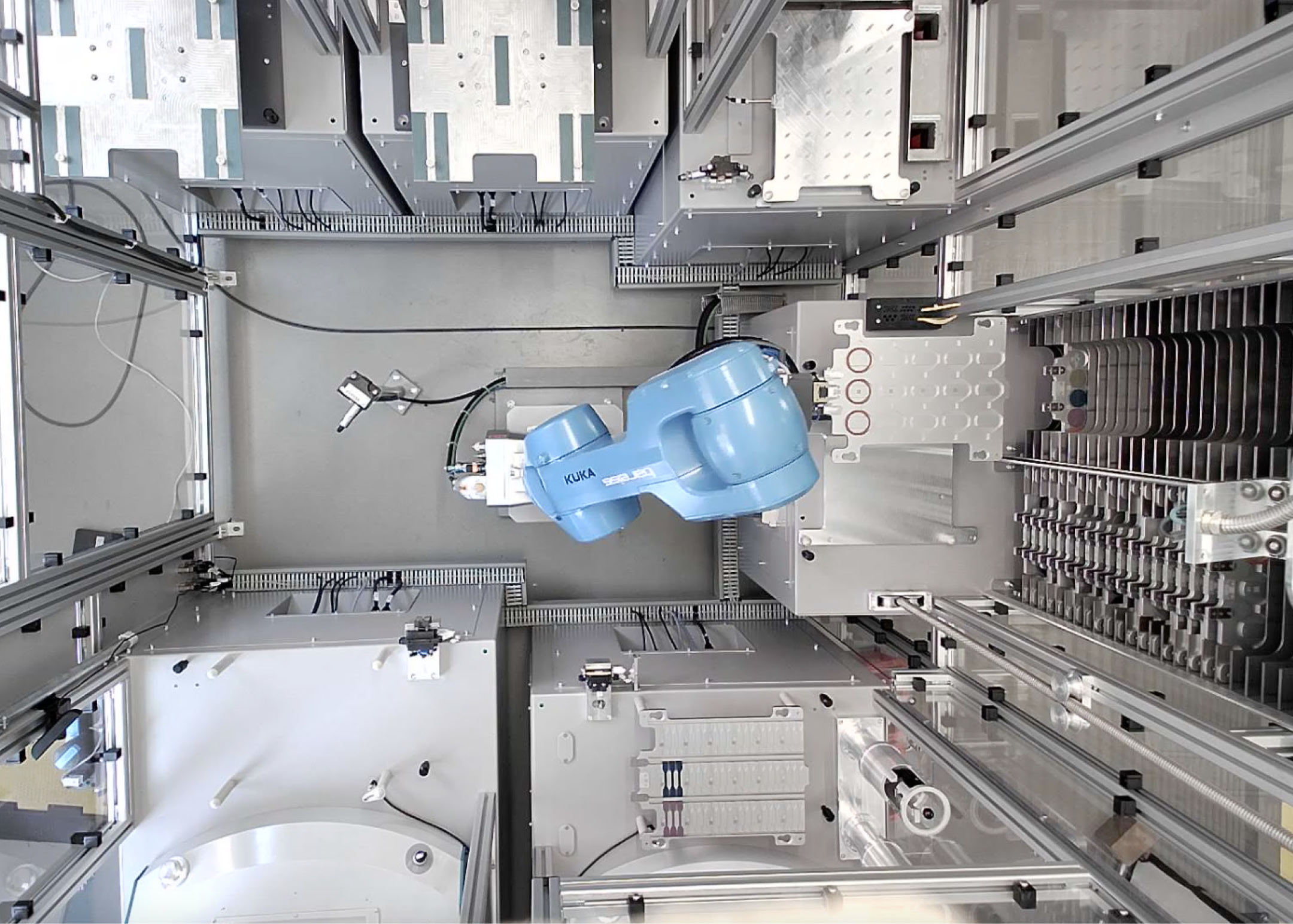

The core requirements for an automated testing laboratory are often very similar, but the implementation is typically tailored to individual needs due to varying testing methods and spatial conditions. With our SmartLab, we have taken both standardization and customization into account and developed a fully automated physical testing lab based on a modular system.

SmartLab intelligently combines the specific requirements of our customers. Various sample geometries can be integrated into the respective stations—just as needed for the testing application. The 6-axis robot distributes the samples within the system automatically using our in-house developed software. Thanks to its unique gripper system, it can transport entire sample trays as well as isolate and place individual samples into the correct testing station using different secondary grippers.

A major focus of the development was on error handling. The system is capable of resolving most issues autonomously with the operator’s approval and provides helpful action recommendations to the user.

Our first SmartLab was delivered with a hardness testing station, a density measurement station, a thickness measurement station, and two tensile testing machines for different specimen geometries (S2 rods and R1 rings).

THE MODULAR SYSTEM AND ITS COMPONENTS

The testing system is built on a solid welded steel frame and features a standardized electronics and hardware interface designed specifically for SmartLab.

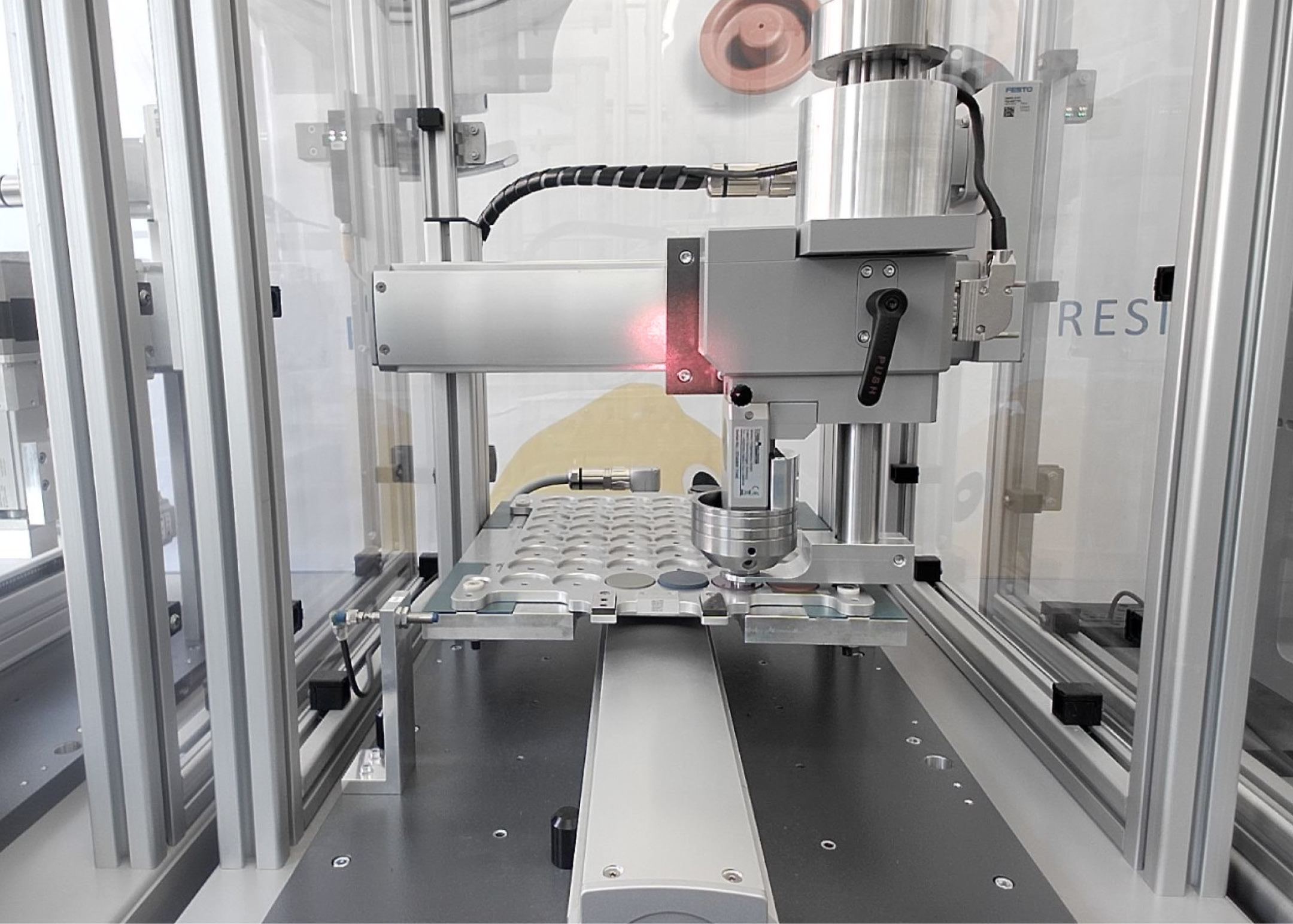

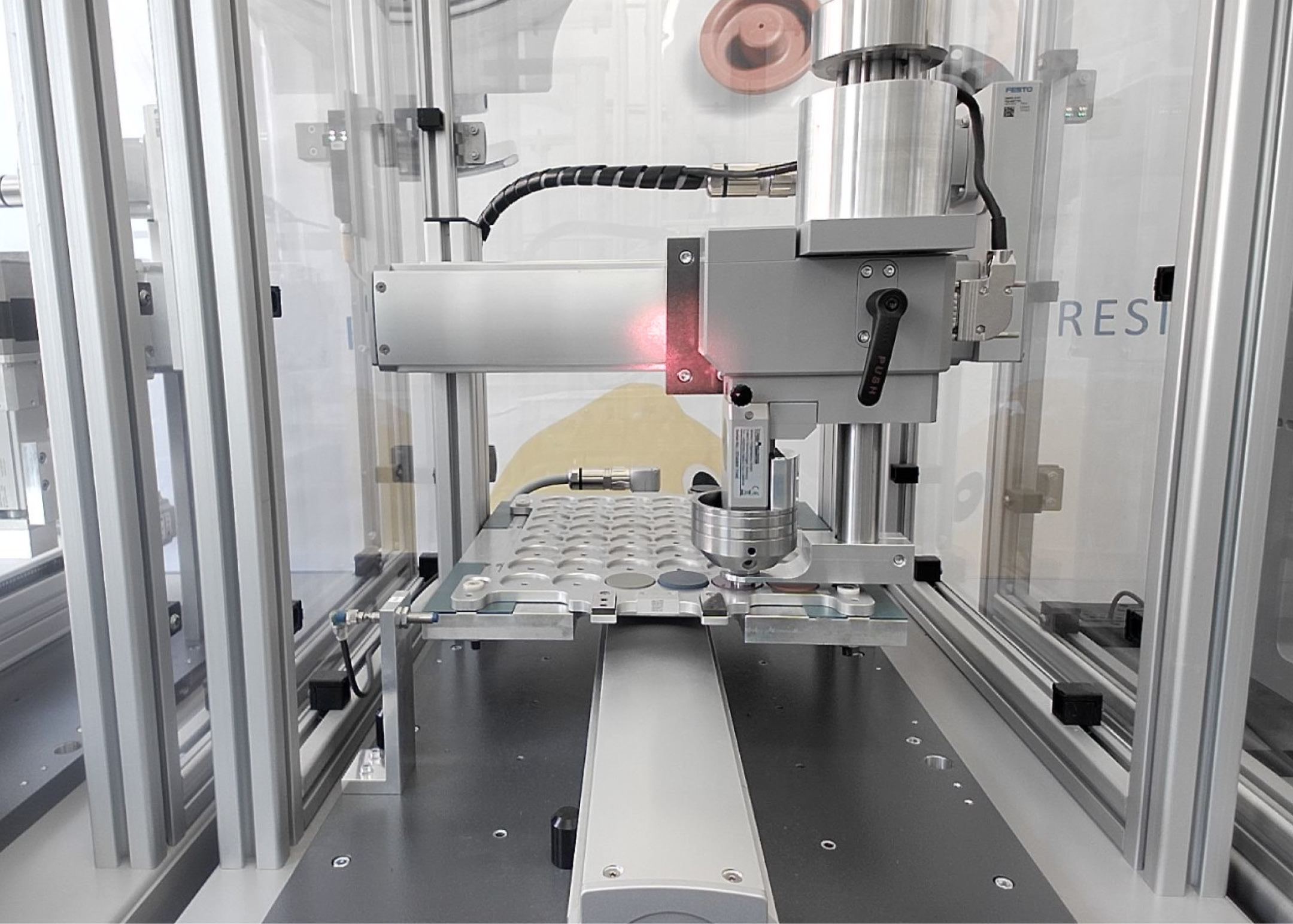

HARDNESS TESTING MODULE

The globally proven Bareiss hardness testing system "digi test II" is used for all available hardness testing methods, featuring appropriate automation for standard-compliant measurement of the specimen at various points. The number and spacing of tests can be individually configured.

Standards: DIN ISO 48-4, ASTM D 2240

TENSILE TESTING MODULE FOR R1 RINGS

For tensile testing, a commercially available standard product is used—this is not a product from the Bareiss portfolio. The evaluation of suitable devices was carried out as part of a round-robin test. Participants were selected to include a wide range of tensile testing machine manufacturers. The required thickness measurement for tensile testing on R1 rings is performed at an additional station.

Standard: DIN 53504

TENSILE TESTING MODULE FOR S2 RODS

For tensile testing, a commercially available standard product is used—this is not a product from the Bareiss portfolio. The evaluation of suitable devices was conducted as part of a preliminary study. Participants were selected to ensure a broad representation of different tensile testing machine manufacturers as well as various types of extensometers. The required thickness measurement for tensile testing on S2 rods is performed at an additional station.

Standard: DIN 53504

DENSITY MEASUREMENT MODULE

The density measurement is based on the buoyancy method. This involves measuring the mass of the test specimens once in air and then multiple times in a beaker filled with water or ethanol after repeated immersion. During development, comparison measurements were conducted using other commercially available devices and in collaboration with accredited laboratories. The result is a concept for automated density testing that has been refined over the years.

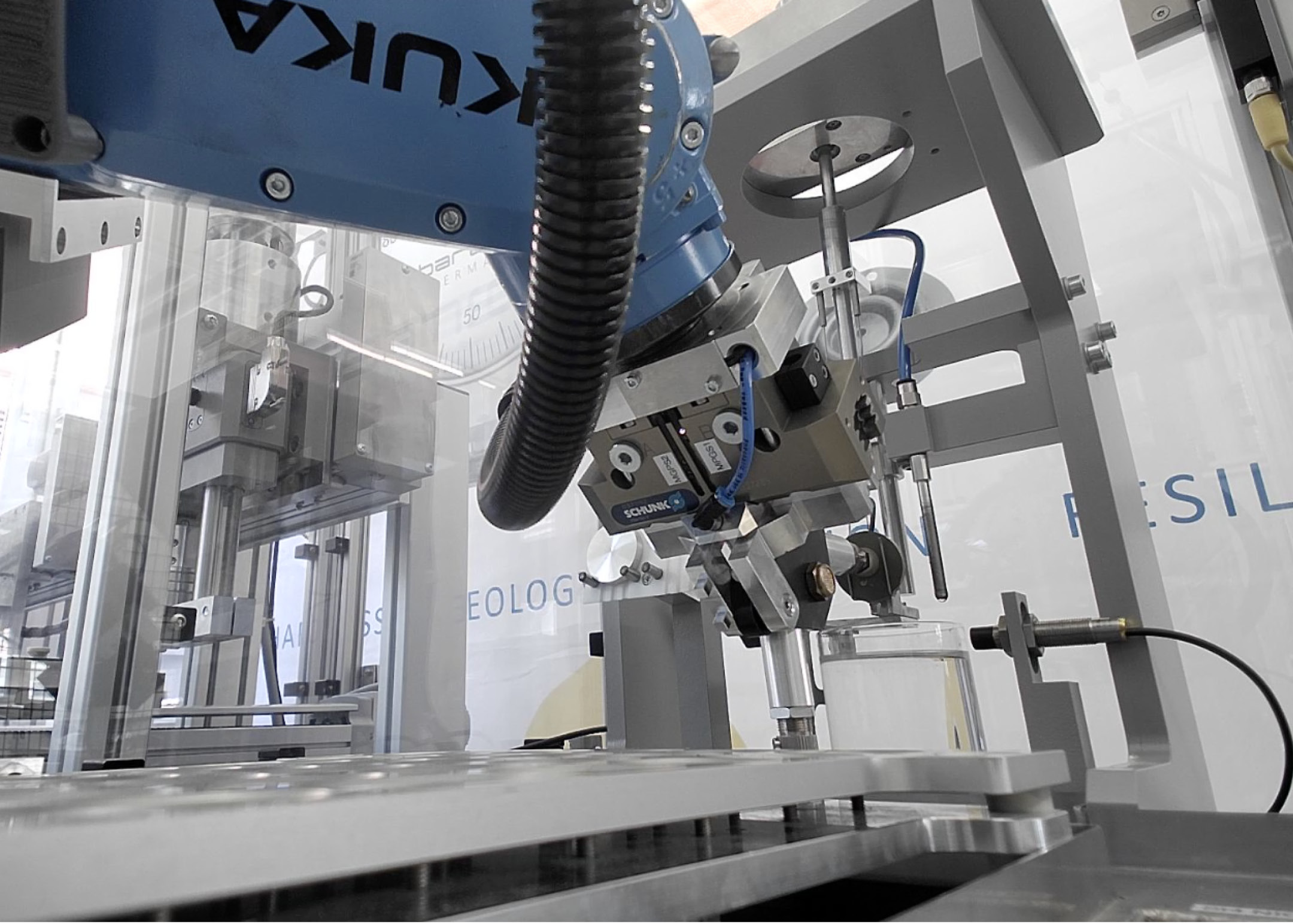

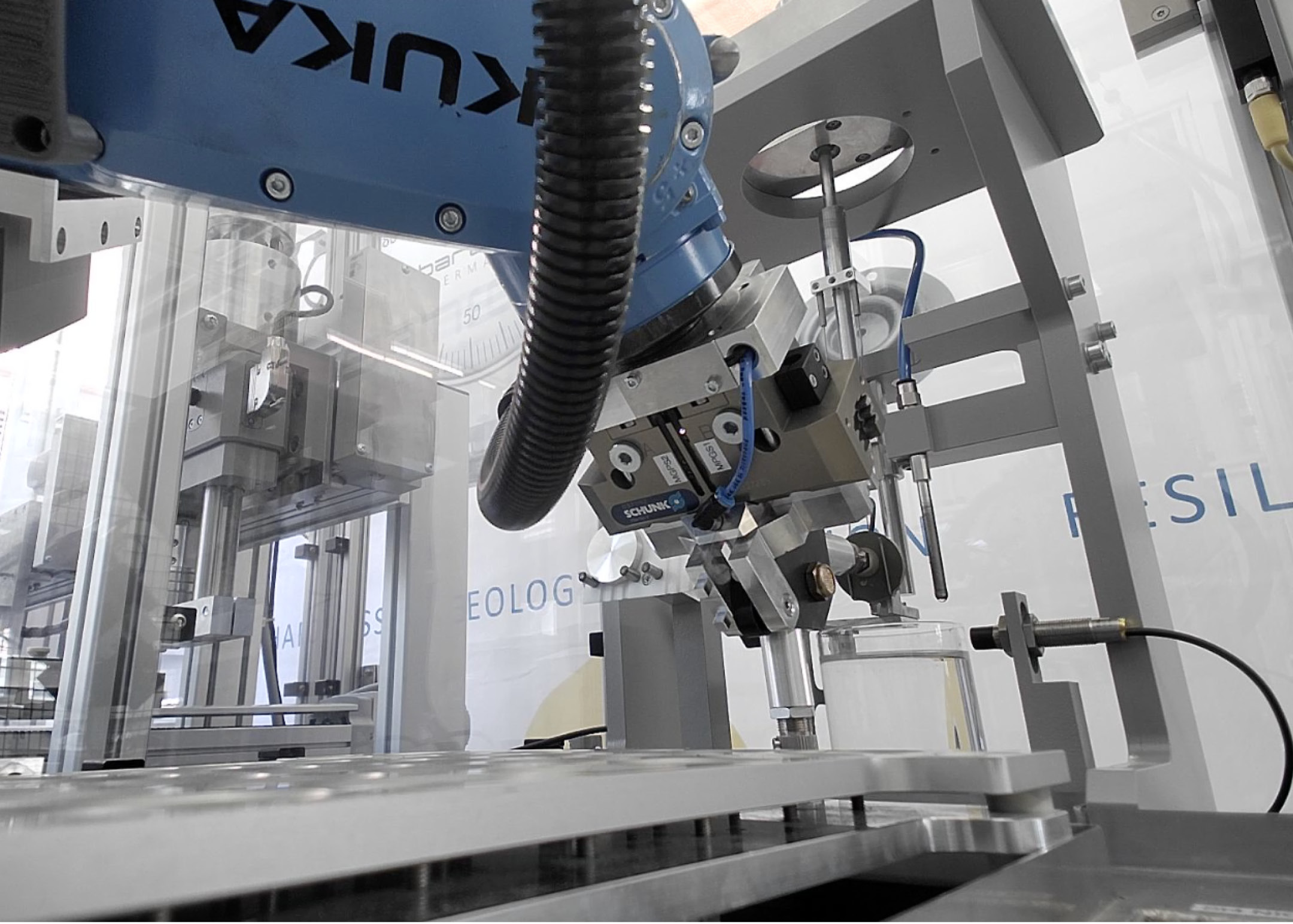

The robot is generally equipped with a dual gripper system, allowing for the separation of wet and dry samples during the density measurement process.

Standards: ISO 2781, DIN EN ISO 1183-1, ASTM D 1817

ROBOT MODULE

An industrial 6-axis robot is used in this module. The handling system is also equipped with a camera to ensure clear identification of the test specimens. In addition, the robot can autonomously attach and operate secondary grippers thanks to the in-house developed software. If different grippers are required for reliable handling of various sample types, a tool change station can be integrated.

BASE MODULE “SAMPLE FEEDING”

An additional module functions as a sample magazine. Each type of specimen is placed on a tray and inserted into a sample rack – this is the interface between human and machine. The specimens are already provided as individual items, ready for automated handling.

SOFTWARE “BareissOne SL”

The proprietary software is used for recording and managing measurement and sample data. Additionally, it controls the testing processes and machine operations. It offers the following features:

User management

Creation of material data (labels can be customized and renamed by users)

Storage of sample data

Administration of individual modules (toolbox available for each device)

Graphical display of current measurement data (all devices can be shown side by side in a live plot)

Data storage in a database

Evaluation tool (e.g., visualization of all (historical) measurements for a batch – identification of trends and new tolerances, etc.)

Interface for data exchange (XML, ASCII, SQLDB, Oracle, …) and database export

EXPANDABILITY

Another advantage of “SmartLab” is its custom expandability, allowing for up to 5 additional modules to be integrated into the system. Feel free to contact us directly for more information.

O-rings, standardized test specimens, seals (limited), soft rubber, highly elastic materials, and plastically deformable substances.

The SmartLab is a modular, fully automated testing laboratory that can be flexibly adapted to various testing methods and spatial concepts. A 6-axis robot with a flexible gripper system handles the specimens and distributes them automatically to the testing stations using specially developed software. Different sample geometries can be integrated without difficulty. A key highlight is the sophisticated error handling system, which provides the user with clear action recommendations.

The SmartLab combines hardness testing, density and thickness measurement, as well as tensile testing machines for various specimen types. Notable features include the high traceability of measurement results and the minimal susceptibility to operator-related errors – because the system “never sleeps.”

The core requirements for an automated testing laboratory are often very similar, but the implementation is typically tailored to individual needs due to varying testing methods and spatial conditions. With our SmartLab, we have taken both standardization and customization into account and developed a fully automated physical testing lab based on a modular system.

SmartLab intelligently combines the specific requirements of our customers. Various sample geometries can be integrated into the respective stations—just as needed for the testing application. The 6-axis robot distributes the samples within the system automatically using our in-house developed software. Thanks to its unique gripper system, it can transport entire sample trays as well as isolate and place individual samples into the correct testing station using different secondary grippers.

A major focus of the development was on error handling. The system is capable of resolving most issues autonomously with the operator’s approval and provides helpful action recommendations to the user.

Our first SmartLab was delivered with a hardness testing station, a density measurement station, a thickness measurement station, and two tensile testing machines for different specimen geometries (S2 rods and R1 rings).

THE MODULAR SYSTEM AND ITS COMPONENTS

The testing system is built on a solid welded steel frame and features a standardized electronics and hardware interface designed specifically for SmartLab.

HARDNESS TESTING MODULE

The globally proven Bareiss hardness testing system "digi test II" is used for all available hardness testing methods, featuring appropriate automation for standard-compliant measurement of the specimen at various points. The number and spacing of tests can be individually configured.

Standards: DIN ISO 48-4, ASTM D 2240

TENSILE TESTING MODULE FOR R1 RINGS

For tensile testing, a commercially available standard product is used—this is not a product from the Bareiss portfolio. The evaluation of suitable devices was carried out as part of a round-robin test. Participants were selected to include a wide range of tensile testing machine manufacturers. The required thickness measurement for tensile testing on R1 rings is performed at an additional station.

Standard: DIN 53504

TENSILE TESTING MODULE FOR S2 RODS

For tensile testing, a commercially available standard product is used—this is not a product from the Bareiss portfolio. The evaluation of suitable devices was conducted as part of a preliminary study. Participants were selected to ensure a broad representation of different tensile testing machine manufacturers as well as various types of extensometers. The required thickness measurement for tensile testing on S2 rods is performed at an additional station.

Standard: DIN 53504

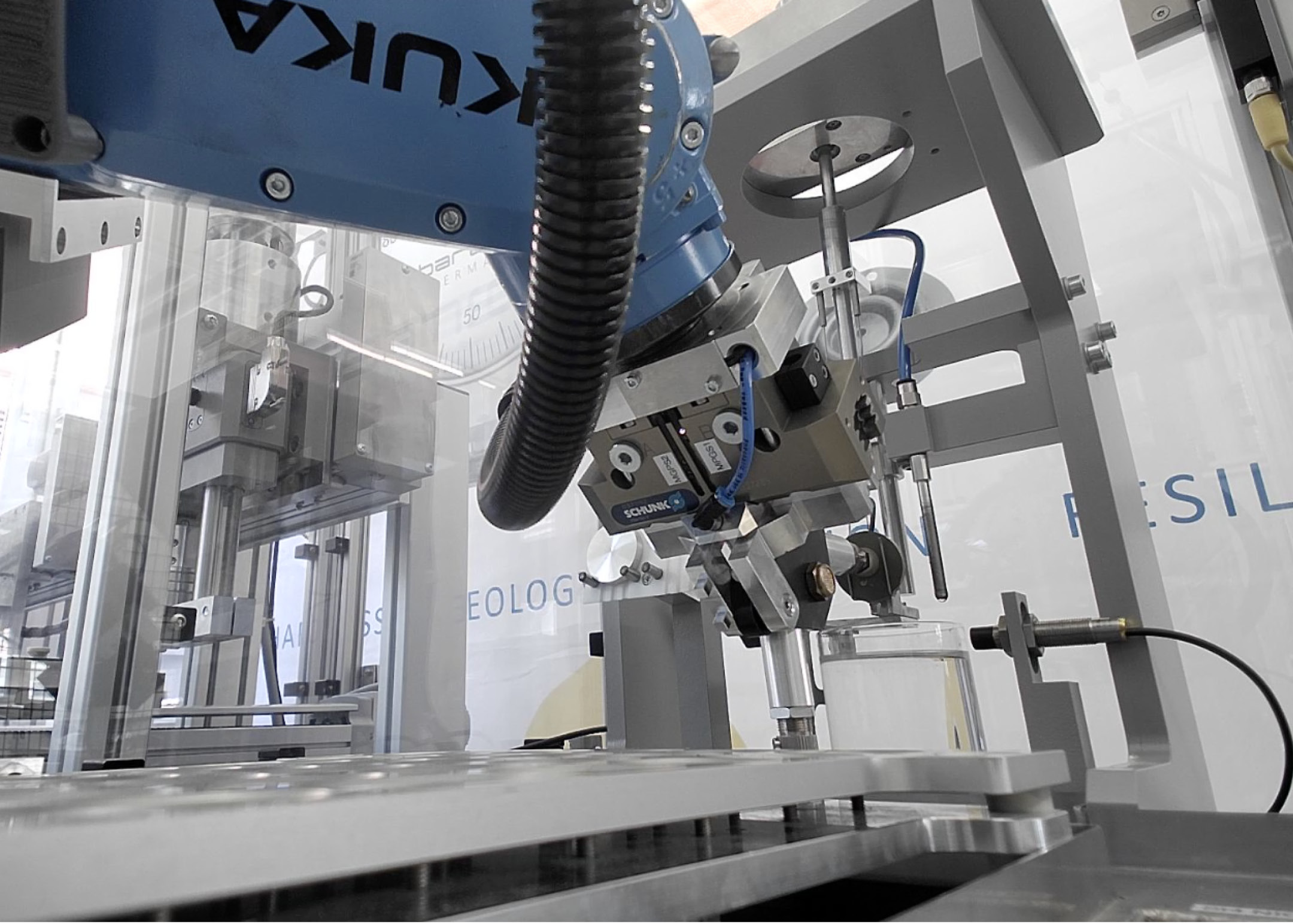

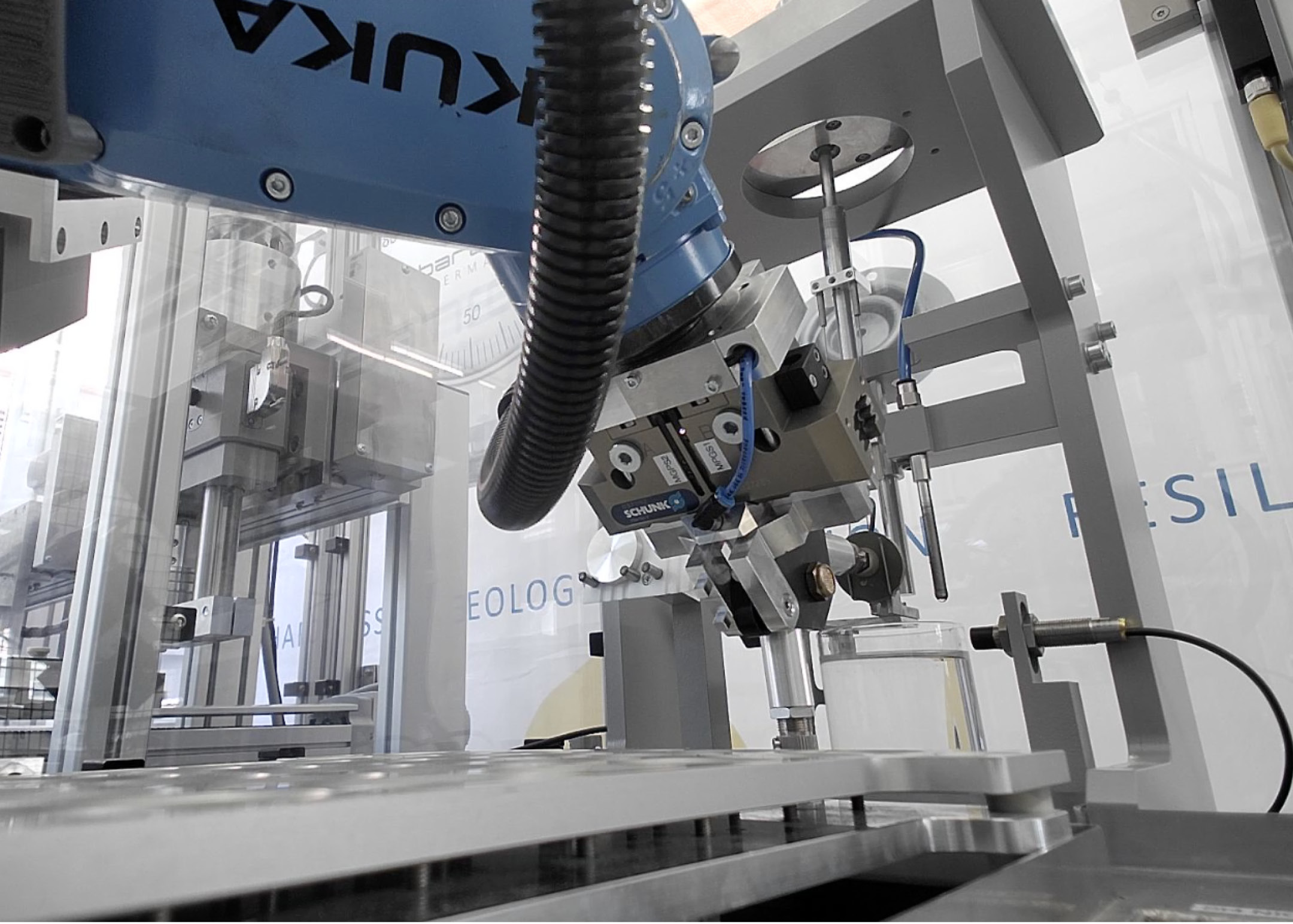

DENSITY MEASUREMENT MODULE

The density measurement is based on the buoyancy method. This involves measuring the mass of the test specimens once in air and then multiple times in a beaker filled with water or ethanol after repeated immersion. During development, comparison measurements were conducted using other commercially available devices and in collaboration with accredited laboratories. The result is a concept for automated density testing that has been refined over the years.

The robot is generally equipped with a dual gripper system, allowing for the separation of wet and dry samples during the density measurement process.

Standards: ISO 2781, DIN EN ISO 1183-1, ASTM D 1817

ROBOT MODULE

An industrial 6-axis robot is used in this module. The handling system is also equipped with a camera to ensure clear identification of the test specimens. In addition, the robot can autonomously attach and operate secondary grippers thanks to the in-house developed software. If different grippers are required for reliable handling of various sample types, a tool change station can be integrated.

BASE MODULE “SAMPLE FEEDING”

An additional module functions as a sample magazine. Each type of specimen is placed on a tray and inserted into a sample rack – this is the interface between human and machine. The specimens are already provided as individual items, ready for automated handling.

SOFTWARE “BareissOne SL”

The proprietary software is used for recording and managing measurement and sample data. Additionally, it controls the testing processes and machine operations. It offers the following features:

User management

Creation of material data (labels can be customized and renamed by users)

Storage of sample data

Administration of individual modules (toolbox available for each device)

Graphical display of current measurement data (all devices can be shown side by side in a live plot)

Data storage in a database

Evaluation tool (e.g., visualization of all (historical) measurements for a batch – identification of trends and new tolerances, etc.)

Interface for data exchange (XML, ASCII, SQLDB, Oracle, …) and database export

EXPANDABILITY

Another advantage of “SmartLab” is its custom expandability, allowing for up to 5 additional modules to be integrated into the system. Feel free to contact us directly for more information.