- Product Overview

- Industry sectors

- Accredited service

- ISO 17025 calibration

- Manufacturer & calibration laboratory

- Rental device & contract measurement

- Seminars & training

- Support & infos

- Company

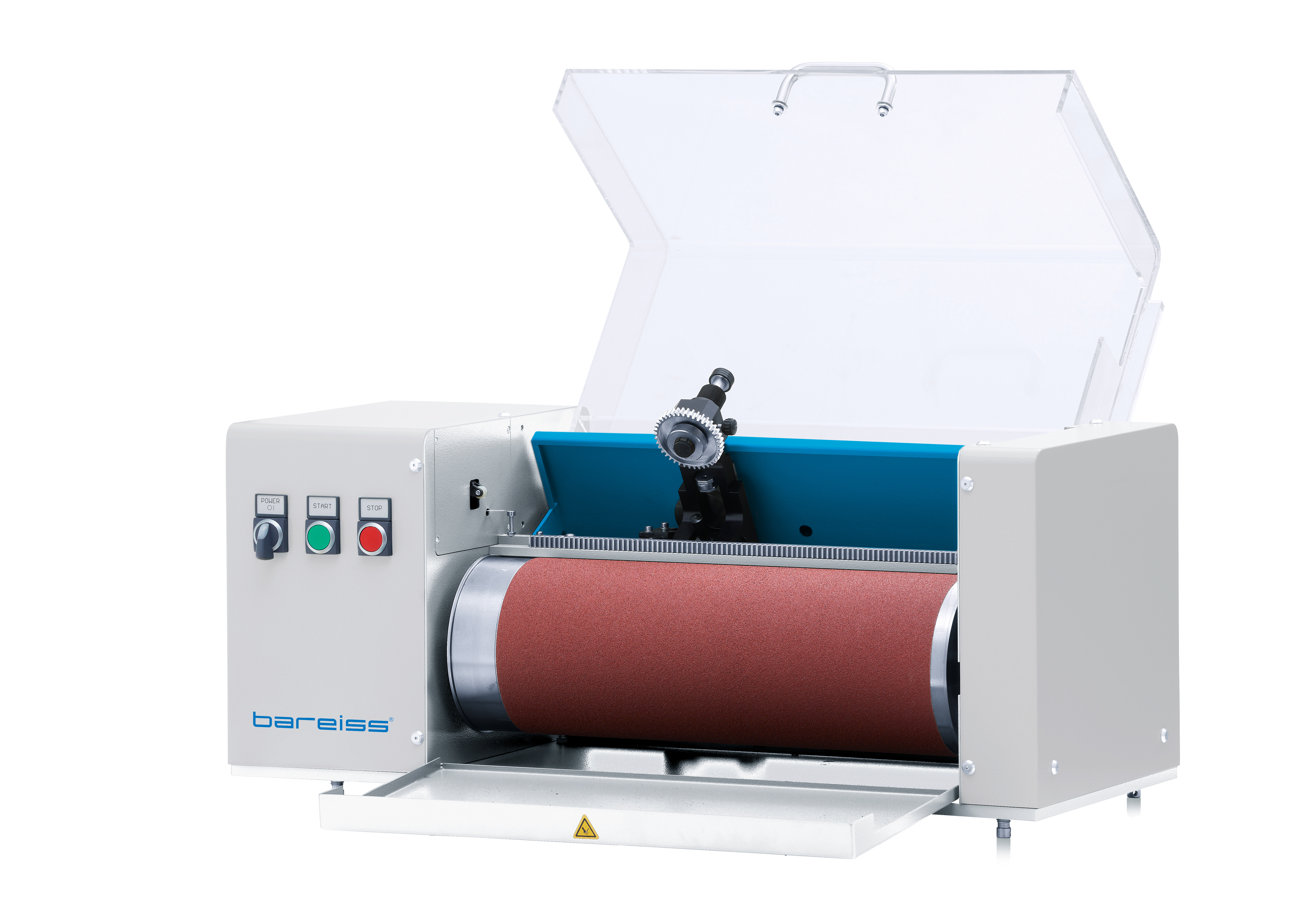

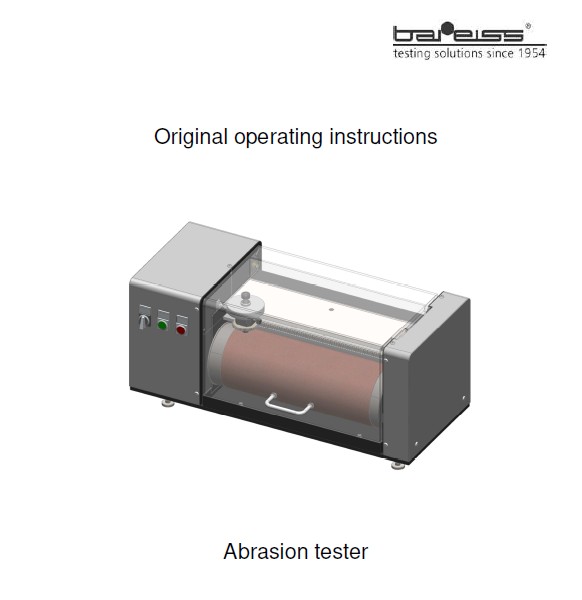

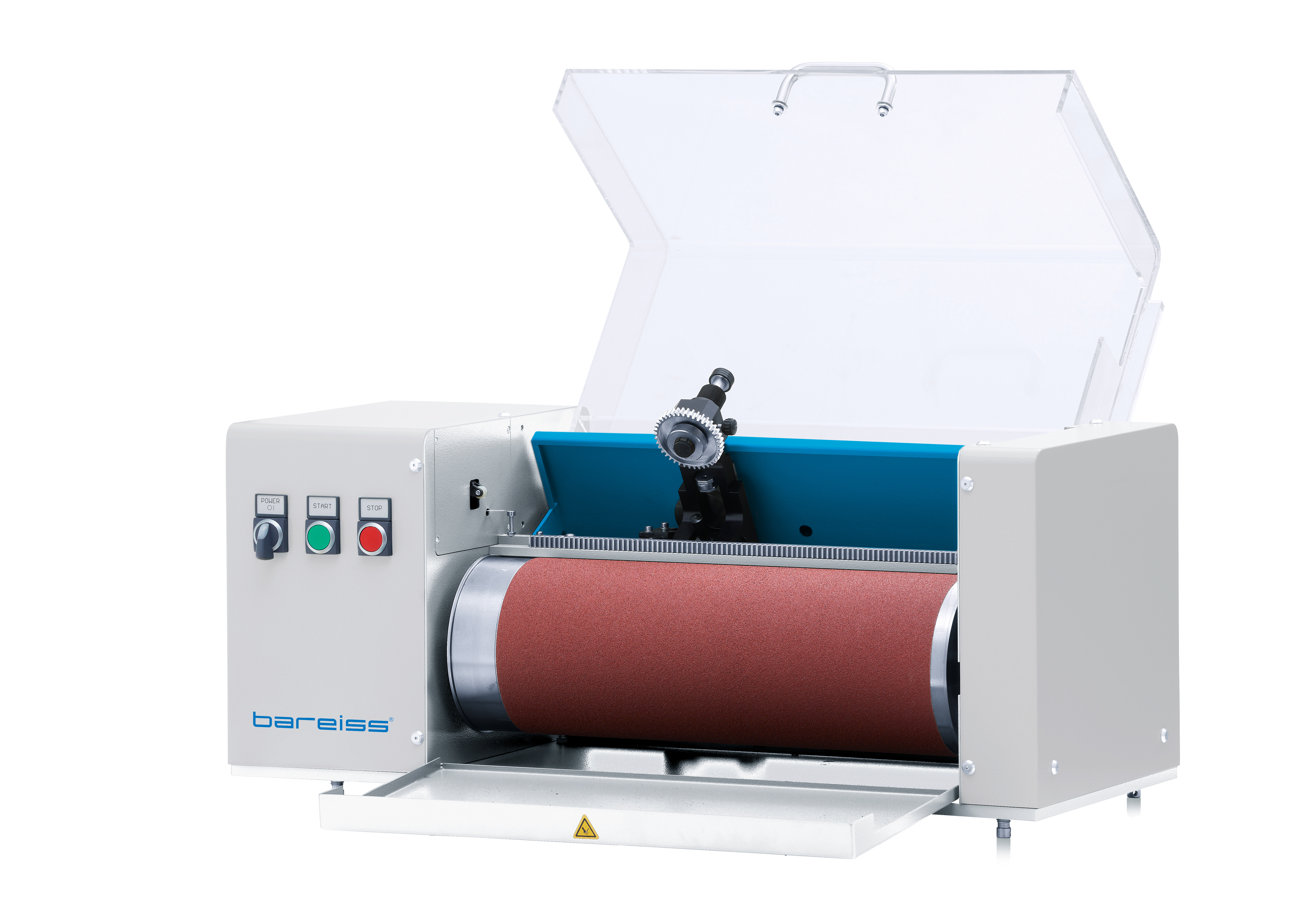

With the Abrasion Testing Machine, you determine the abrasion resistance of elastomers by measuring the material loss under abrasive loading. The testing device guides the fixed or rotating material sample with defined compacted pressure over a circulating abrasive sheet, subjecting it to frictional strain.

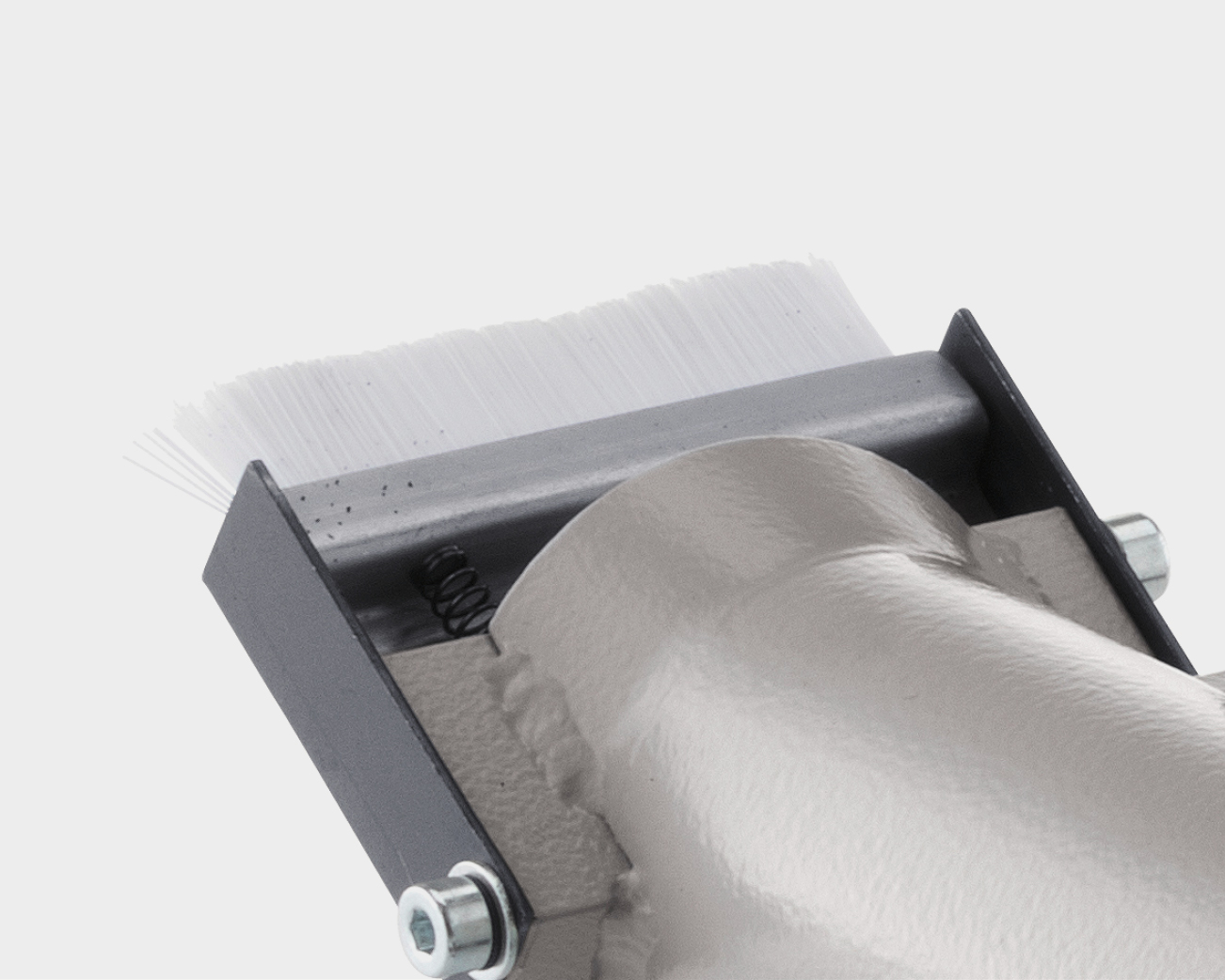

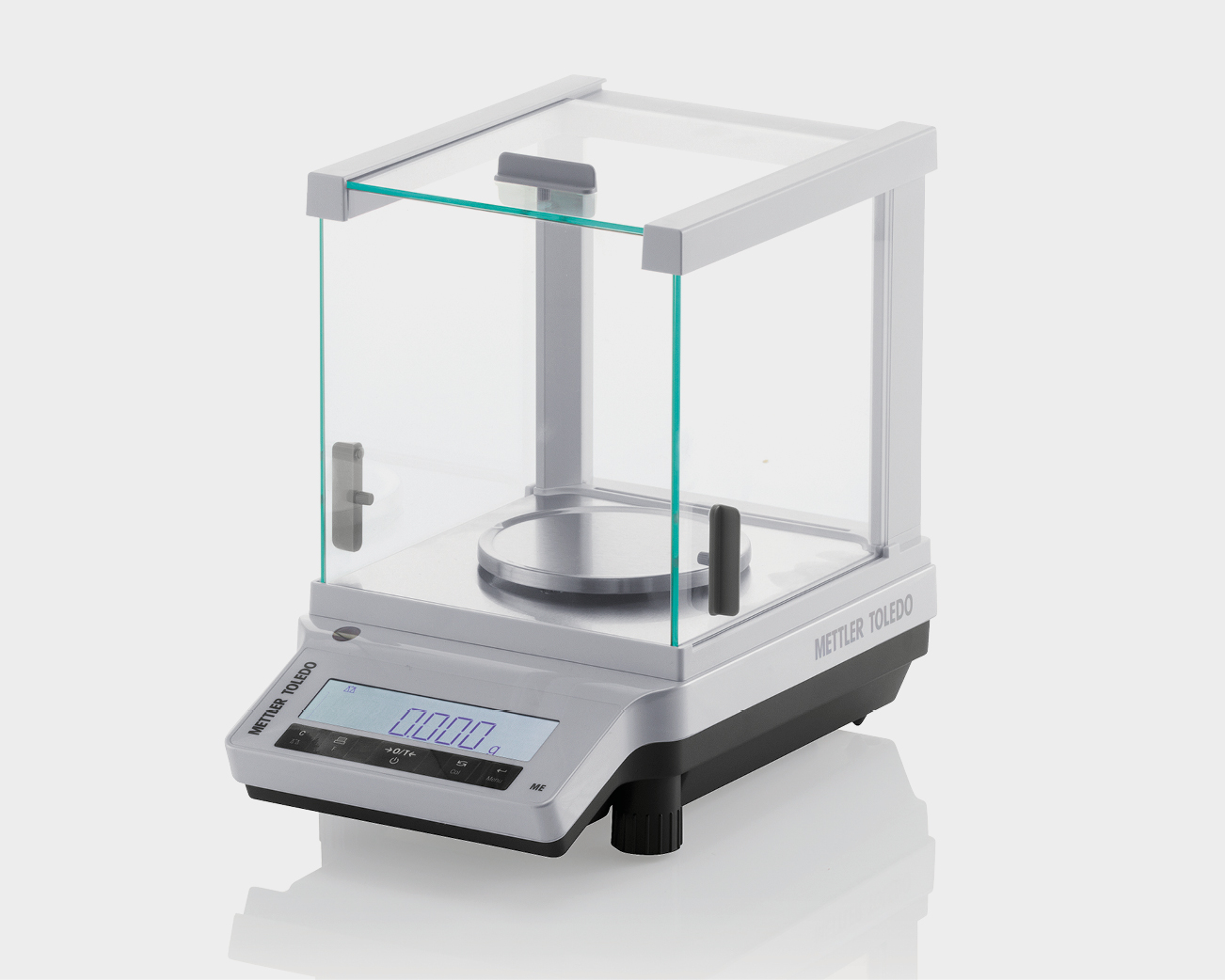

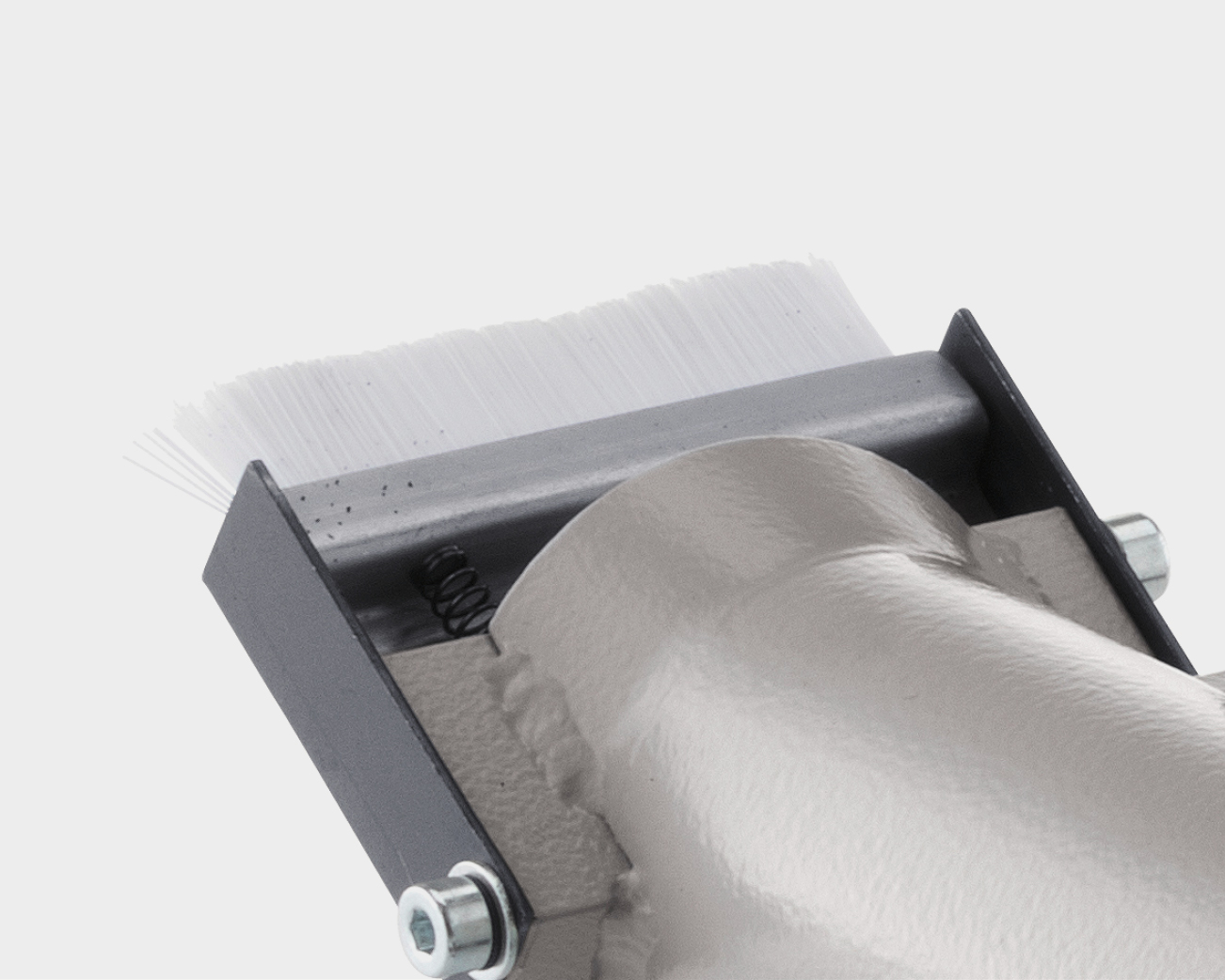

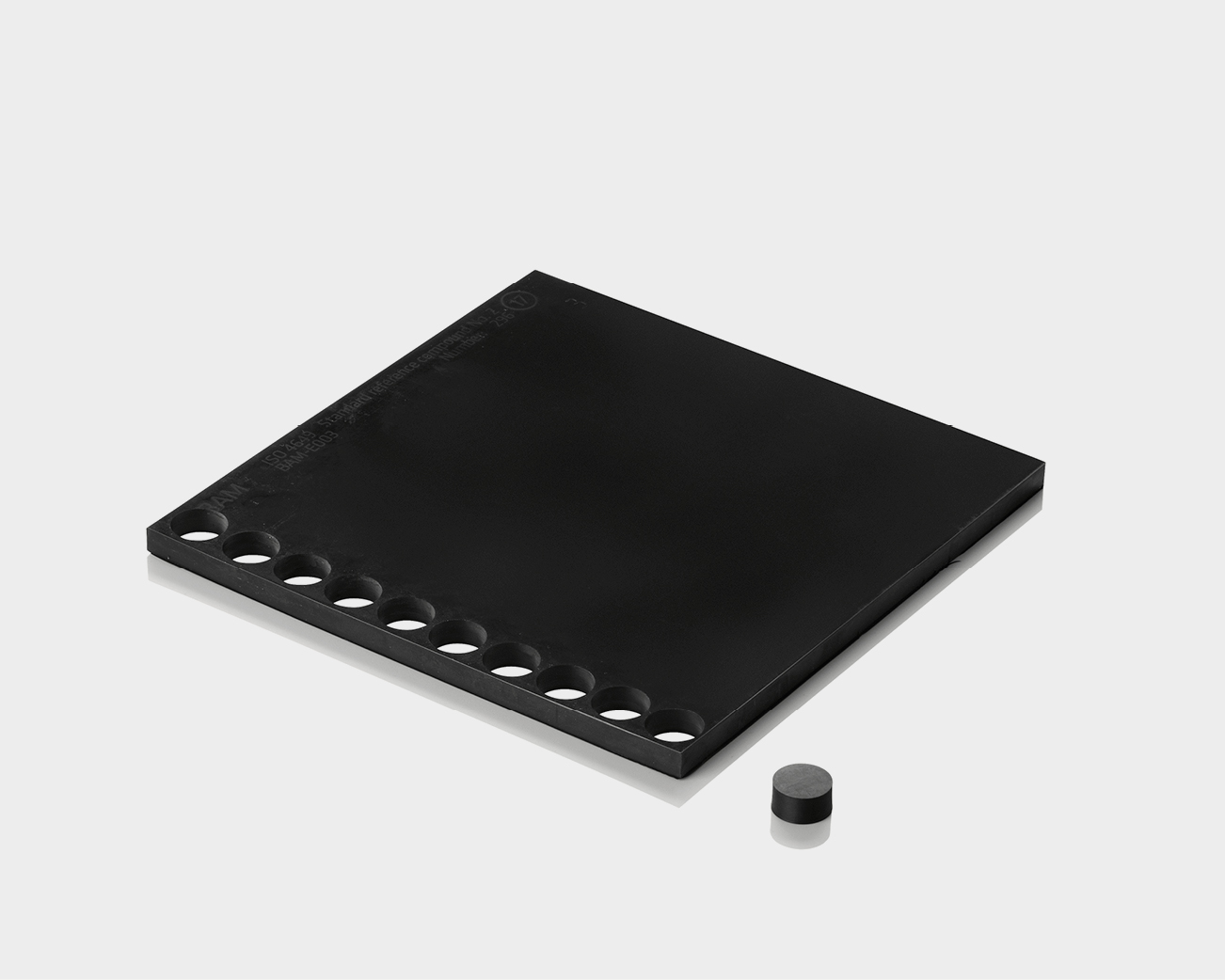

The abrasive sheet, conditioned using a reference elastomer sample beforehand, ensures controlled abrasive wear of the specimen. The loss of material of the sample, determined by weighing before and after the testing, provides insight ito the elastomer's abrasion resistance. The sample's strain along the abrasion path, either 20 or 40 meters, can be adjusted depending on your requirements. An integrated cleaning mechanism, which you can connect to your industrial vacuum system using a provided adapter, ensures a consistently clean abrasive sheet during the abrasion process.

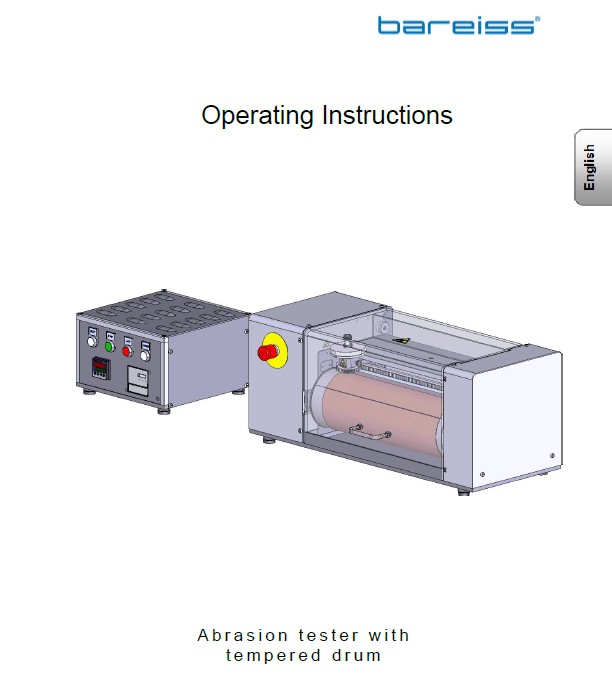

Optionally, the machine is available with a tempered drum (up to 100°C) to measure abrasion hardness under real conditions on the abrasion surface.

Maximum flexibility for your measurement requirements

Conduct various types of abrasion testing with one machine: choose between a fixed (Method A) or rotating (Method B) sample and select either a 20 m friction path for very soft samples or a 40 m friction path.

Abrasion Testing Machine

Specimen holder with weight receptacle for round samples Ø 16 mm

Easy operation

With the sample fixed in the wuick-release holder and simple conditioning of the abrasive sheet, the abrasion testing machine is quickly ready for use.

Safe and clean functioning

Thanks to the integrated cleaning mechanism, the test abrasive sheet is automatically cleaned during the testing. This saves time and reduces user's influence. The lowerable protective housing ensures further cleanliness and th user's safety.

Testing under real conditions

Use our additional tempered drum up to 100°C to simulate the temperature in the material's intended field of application.

Other features

Material testing and development of tires, conveyor belts, shoes, flooring, and many other materials used in abrasive applications

Increase in the compression force of the sample by 10 N

Abrasion steel sample

Circular cutting device

Vacuum cleaner

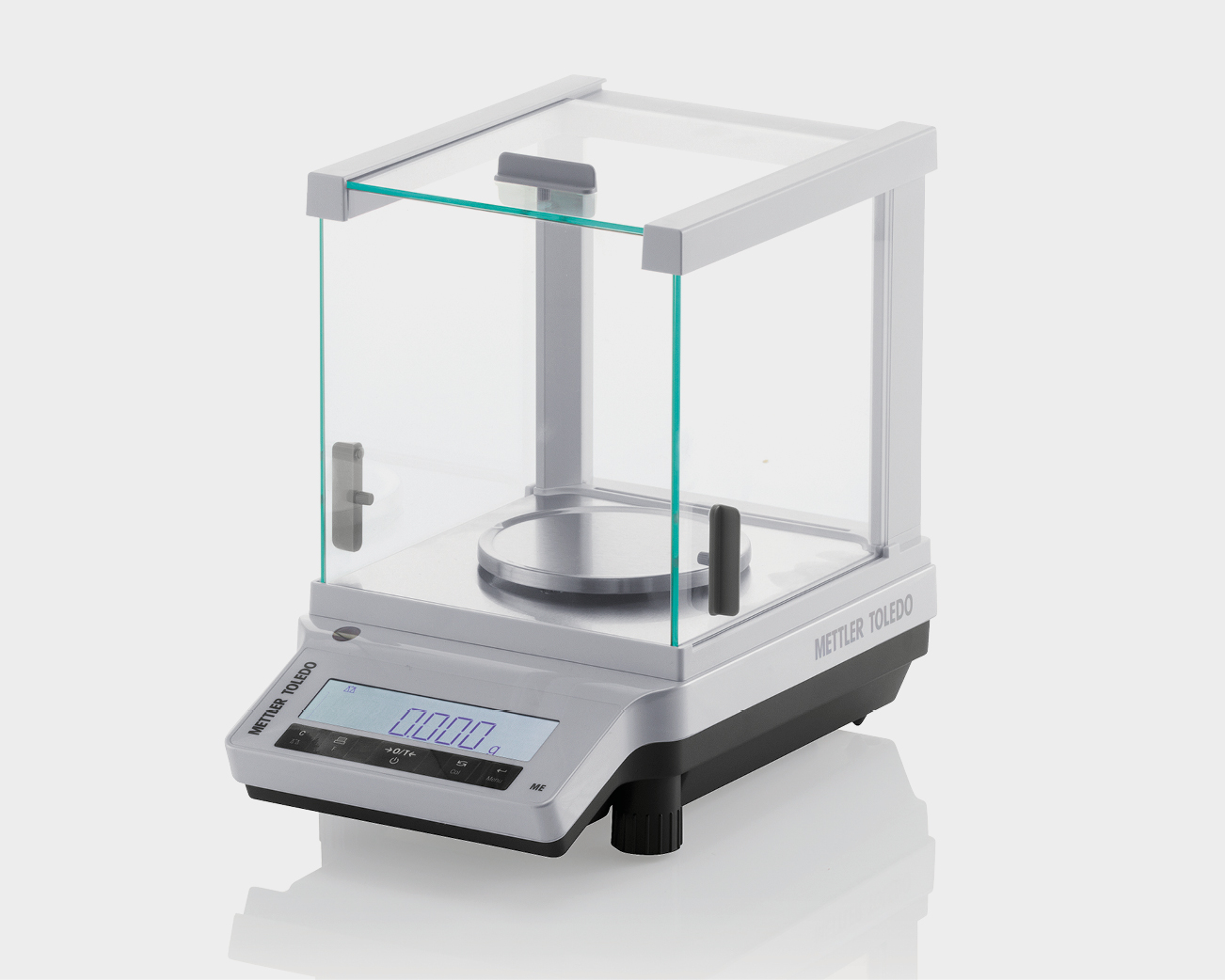

Electronic analytical balance

Dust cover

Replacement brushes

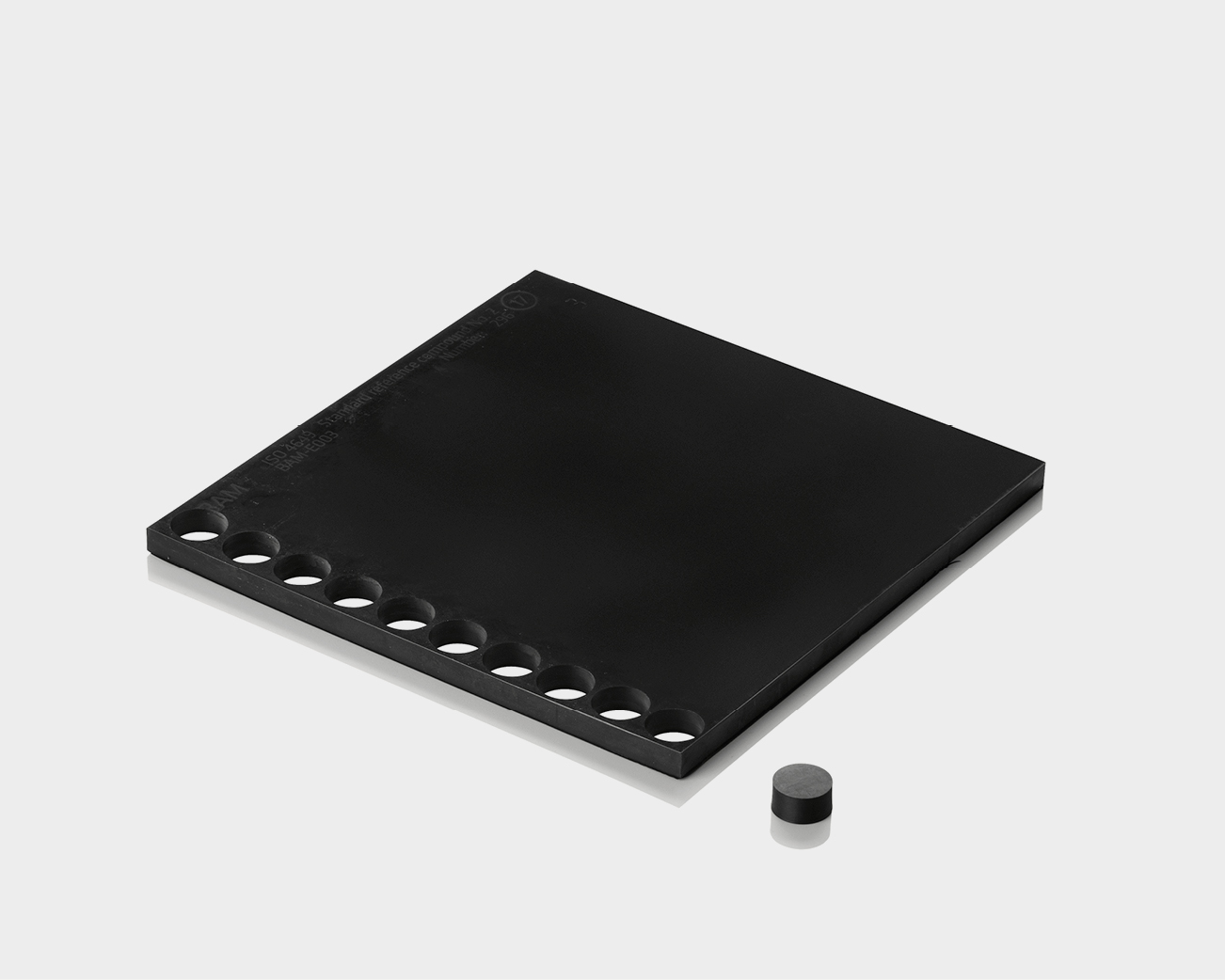

Reference block

according to ISO 4649, Method A or B

Replacement test abrasive sheets

DAkkS accredited calibration certificate

Diameter: 16 mm (Tolerance: +/- 2 mm)

Minimum material thickness: mind. 6 mm

Dim. W x H x D: min. 76 x 33 x 36 cm

max. 76 x 63 x 50 cm

Weight: 47,00 kg

Power supply: 100 - 240 VAC; 50/60 Hz; 100 VA

Protection class: IP 20

Abrasion distance: 20 m/40 m

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happpy to answer any questions you might have about hardness testing!

Phone+49 7305 9642-0

Fax +49 7305 9642-22

Email

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

Automated testing device for determining the abrasive characteristics of elastomers based on the loss of material during abrasion testing. If the density of the material is known, the accuring loss of volume can also be determined additionally.

![]() Bareiss Silverline 25

Bareiss Silverline 25

New colors, lived responsibility – coatings for a better future

The transition to the new coating will begin mid-year. During the transition period, some devices may still be delivered with previous coating. We kindly ask for your understanding that the new coating cannot be guaranteed.

Diameter: 16 mm (Tolerance: +/- 2 mm)

Minimum material thickness: mind. 6 mm

Dim. W x H x D: min. 76 x 33 x 36 cm

max. 76 x 63 x 50 cm

Weight: 47,00 kg

Power supply: 100 - 240 VAC; 50/60 Hz; 100 VA

Protection class: IP 20

Abrasion distance: 20 m/40 m

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happpy to answer any questions you might have about hardness testing!

Phone+49 7305 9642-0

Fax +49 7305 9642-22

Email sales@bareiss.de

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

With the Abrasion Testing Machine, you determine the abrasion resistance of elastomers by measuring the material loss under abrasive loading. The testing device guides the fixed or rotating material sample with defined compacted pressure over a circulating abrasive sheet, subjecting it to frictional strain.

The abrasive sheet, conditioned using a reference elastomer sample beforehand, ensures controlled abrasive wear of the specimen. The loss of material of the sample, determined by weighing before and after the testing, provides insight ito the elastomer's abrasion resistance. The sample's strain along the abrasion path, either 20 or 40 meters, can be adjusted depending on your requirements. An integrated cleaning mechanism, which you can connect to your industrial vacuum system using a provided adapter, ensures a consistently clean abrasive sheet during the abrasion process.

Optionally, the machine is available with a tempered drum (up to 100°C) to measure abrasion hardness under real conditions on the abrasion surface.

Maximum flexibility for your measurement requirements

Conduct various types of abrasion testing with one machine: choose between a fixed (Method A) or rotating (Method B) sample and select either a 20 m friction path for very soft samples or a 40 m friction path.

Easy operation

With the sample fixed in the wuick-release holder and simple conditioning of the abrasive sheet, the abrasion testing machine is quickly ready for use.

Safe and clean functioning

Thanks to the integrated cleaning mechanism, the test abrasive sheet is automatically cleaned during the testing. This saves time and reduces user's influence. The lowerable protective housing ensures further cleanliness and th user's safety.

Testing under real conditions

Use our additional tempered drum up to 100°C to simulate the temperature in the material's intended field of application.

Other features

Abrasion Testing Machine

Specimen holder with weight receptacle for round samples Ø 16 mm

Increase in the compression force of the sample by 10 N

Abrasion steel sample

Circular cutting device

Vacuum cleaner

Electronic analytical balance

Dust cover

Replacement brushes

Reference block

according to ISO 4649, Method A or B

Replacement test abrasive sheets

DAkkS accredited calibration certificate