- Product Overview

- Industry sectors

- Accredited service

- ISO 17025 calibration

- Manufacturer & calibration laboratory

- Rental device & contract measurement

- Seminars & training

- Support & infos

- Company

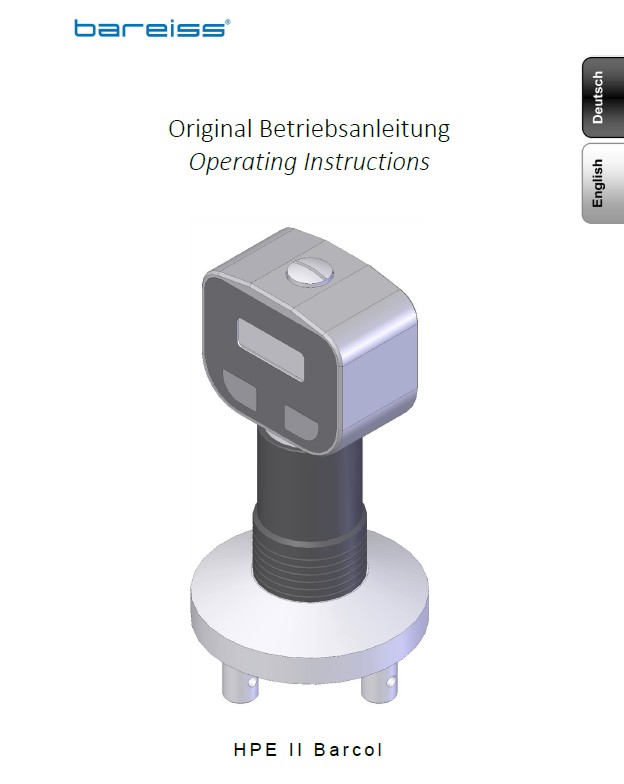

The hardness testing of solid materials such as glass fiber reinforced plastics, thermosetting plastics, hard thermoplastics and light metals can be reliably undertaken with our digital Barcol handheld hardness tester. For correct measuring results, the test specimens should have a flat surface and a minimum thickness of 1.5 mm. Thanks to the stabilizing ring with a four-point support, the measuring device can be placed on the test specimen in a vertical position, so that it will not tilt during manual measurements and can be correctly loaded, with the necessary high contact force. The hardness tester announces the successful measuring with an acoustic signal, showing the determined hardness value on its display. The internal memory records up to 300 measured values, which can be exported through the RS-232 interface if necessary.

Barcol handheld hardness tester with stabilizing ring

Battery

RS-232 data cable

Transport case

Hardness measuring on plate-shaped specimens from glass fiber reinforced plastics, thermosetting plastics and hard thermoplstics.

DAkkS accredited calibration certificate

Reference block for Barcol

with DAkkS accredited calibration certificate

Barcol test stand

Software

Plate-shaped samples with at least 1,5 mm thickness.

1 Barcol

Dim. W x H x D: 7 x 4 x 16 cm

Weight: 0,37 kg

Power supply: Lithium-Battery 3,6 V, Size 1/2 AA

Protection class: IP 30

Operating time: 2000 Working hours

RS-232 Interface

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email

Opening hours:

Monday- Thursday: 07.00 - 16.00 Uhr

Friday: 07.00 - 12.00 Uhr

Digital handheld hardness tester with stabilizing ring for the recording of the Barcol hardness on plate-shaped test specimens from glass fiber reinforced plastics, thermosetting plastics, hard thermoplastics and light metals.

Plate-shaped samples with at least 1,5 mm thickness.

1 Barcol

Dim. W x H x D: 7 x 4 x 16 cm

Weight: 0,37 kg

Power supply: Lithium-Battery 3,6 V, Size 1/2 AA

Protection class: IP 30

Operating time: 2000 Working hours

RS-232 Interface

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email sales@bareiss.de

Opening hours:

Monday- Thursday: 07.00 - 16.00 Uhr

Friday: 07.00 - 12.00 Uhr

The hardness testing of solid materials such as glass fiber reinforced plastics, thermosetting plastics, hard thermoplastics and light metals can be reliably undertaken with our digital Barcol handheld hardness tester. For correct measuring results, the test specimens should have a flat surface and a minimum thickness of 1.5 mm. Thanks to the stabilizing ring with a four-point support, the measuring device can be placed on the test specimen in a vertical position, so that it will not tilt during manual measurements and can be correctly loaded, with the necessary high contact force. The hardness tester announces the successful measuring with an acoustic signal, showing the determined hardness value on its display. The internal memory records up to 300 measured values, which can be exported through the RS-232 interface if necessary.

Barcol handheld hardness tester with stabilizing ring

Battery

RS-232 data cable

Transport case

DAkkS accredited calibration certificate

Reference block for Barcol

with DAkkS accredited calibration certificate

Barcol test stand

Software