- Product Overview

- Industry sectors

- Accredited service

- ISO 17025 calibration

- Manufacturer & calibration laboratory

- Rental device & contract measurement

- Seminars & training

- Support & infos

- Company

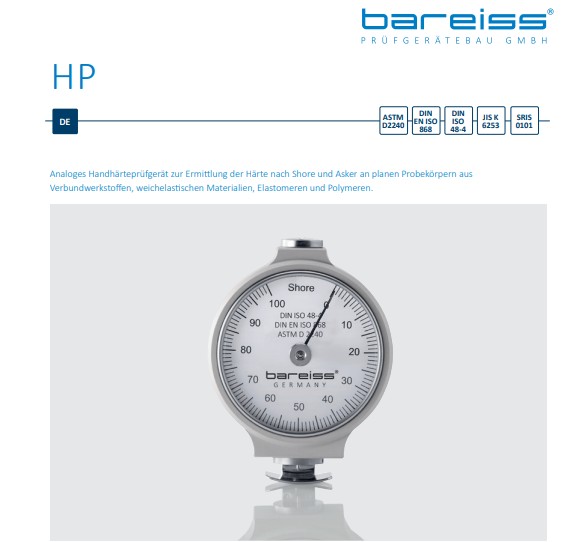

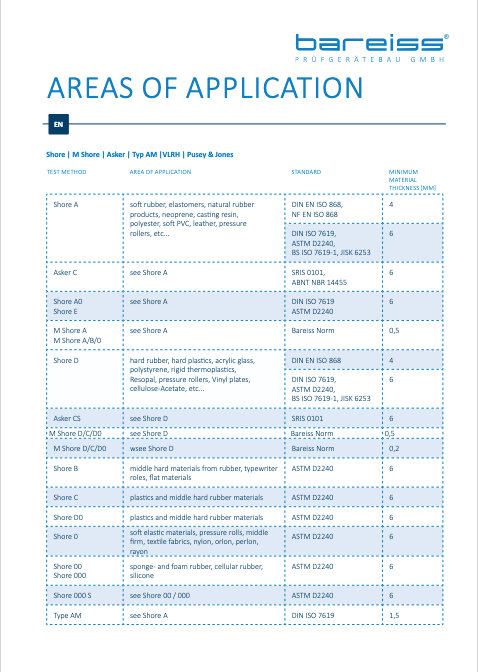

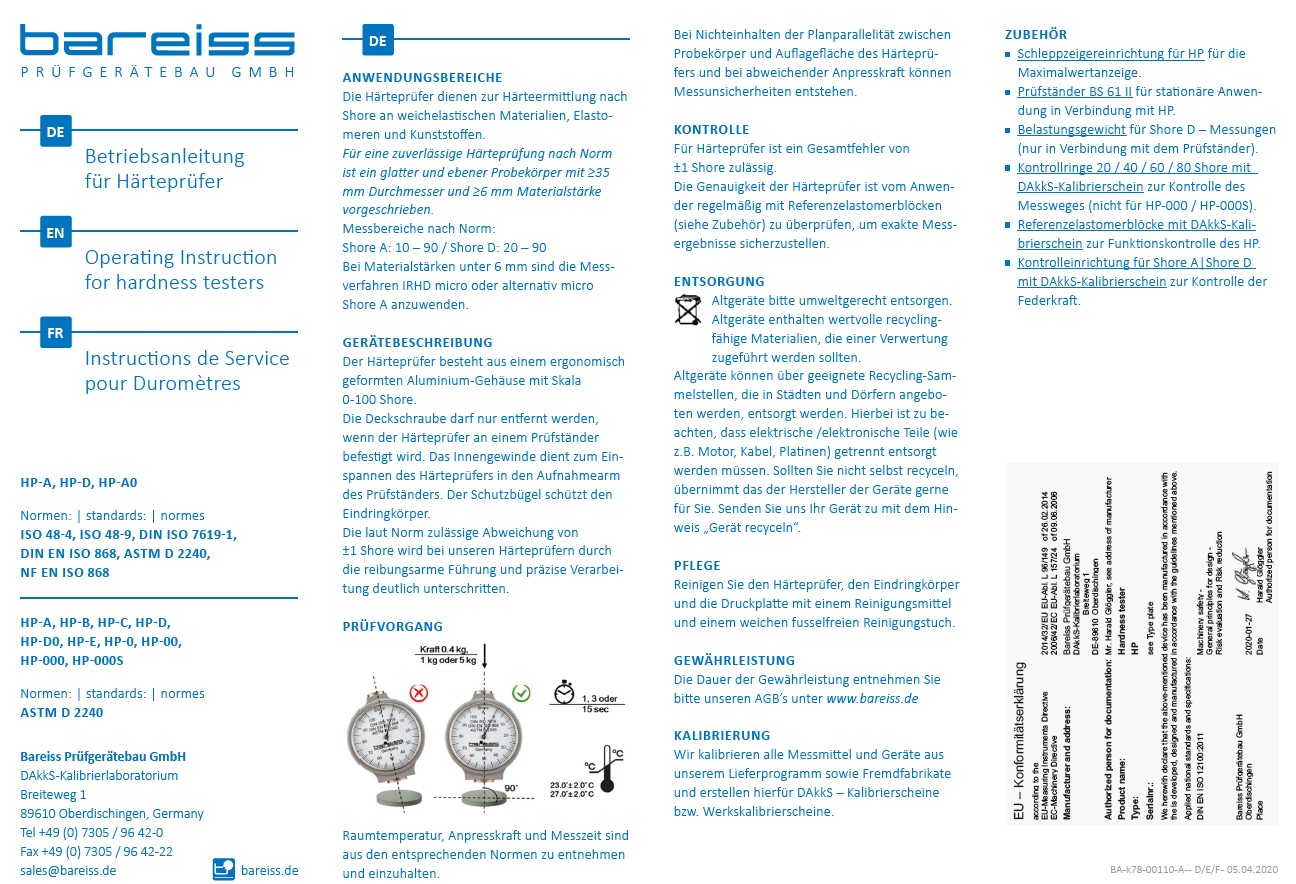

The HP is used for hardness determination according to Shore scale on flexible materials, elastomers, and plastics. For reliable hardness testing according to standard, a smooth and flat test specimen with a diameter of ≥ 35 mm and a material thickness of ≥ 6 mm is required. The handheld hardness tester is placed vertically on the surface of the test specimen and manually pressed. The specially designed, high-precision mechanics ensure minimal friction of the meter movement, thereby ensuring high measurement precision.

The determined hardness can be read on the analog display of the HP during the measurement. the precision of the hardness tester should be regularly verified by the user using standard blocks to ensure accurate measuring results.

Lightweight and compact

The compact size of the handheld hardness tester allows for convenient transport to the desired site of operation. Whether in the factory, warehouse, receipt of goods, or during quality inspections at the supplier, the HP is easy to carry and well protected by the practical carrying case.

Carrying case

Two measurements in one

With the optional maximum indicating pointer, the peak value of the hardness test is displayed on the dial even after the measurement.

Universally applicable

In addition to its use as a flexible and lightweight handheld hardness testing device, the HP, when expanded with a test stand, also offers a stationary solution that adapts to your requirements. When combined with our manual test stand BS 61 II, the HP also serves as a tabletop unit for measurements in a laboratory enviroment.

Other features

Hardness determination of composite materials, flexible materials, elastomers, plastics, foams, as well as automotivee interior equipment

BS 61 II, manual test stand

Elasticity control unit

Shore A/Shore D

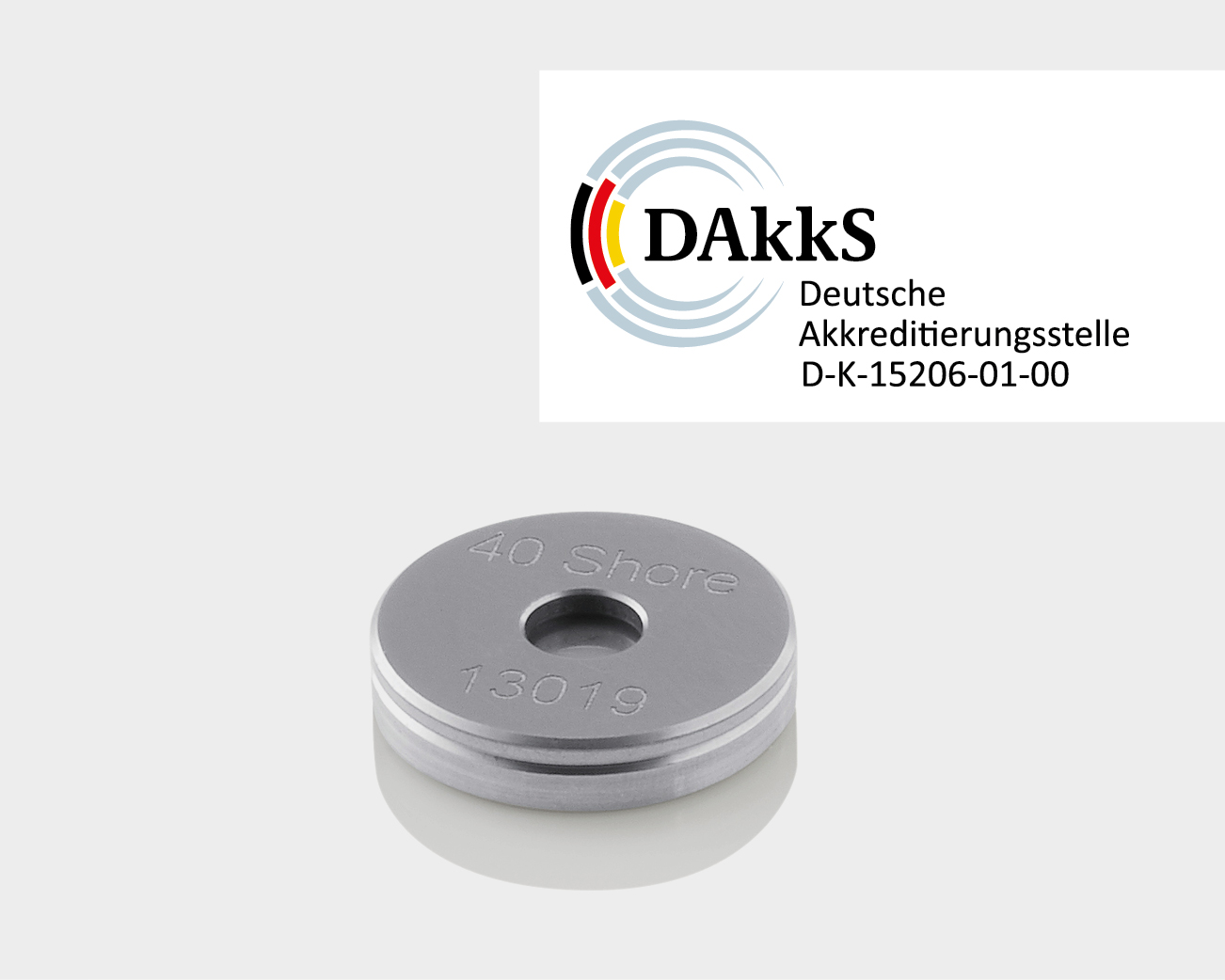

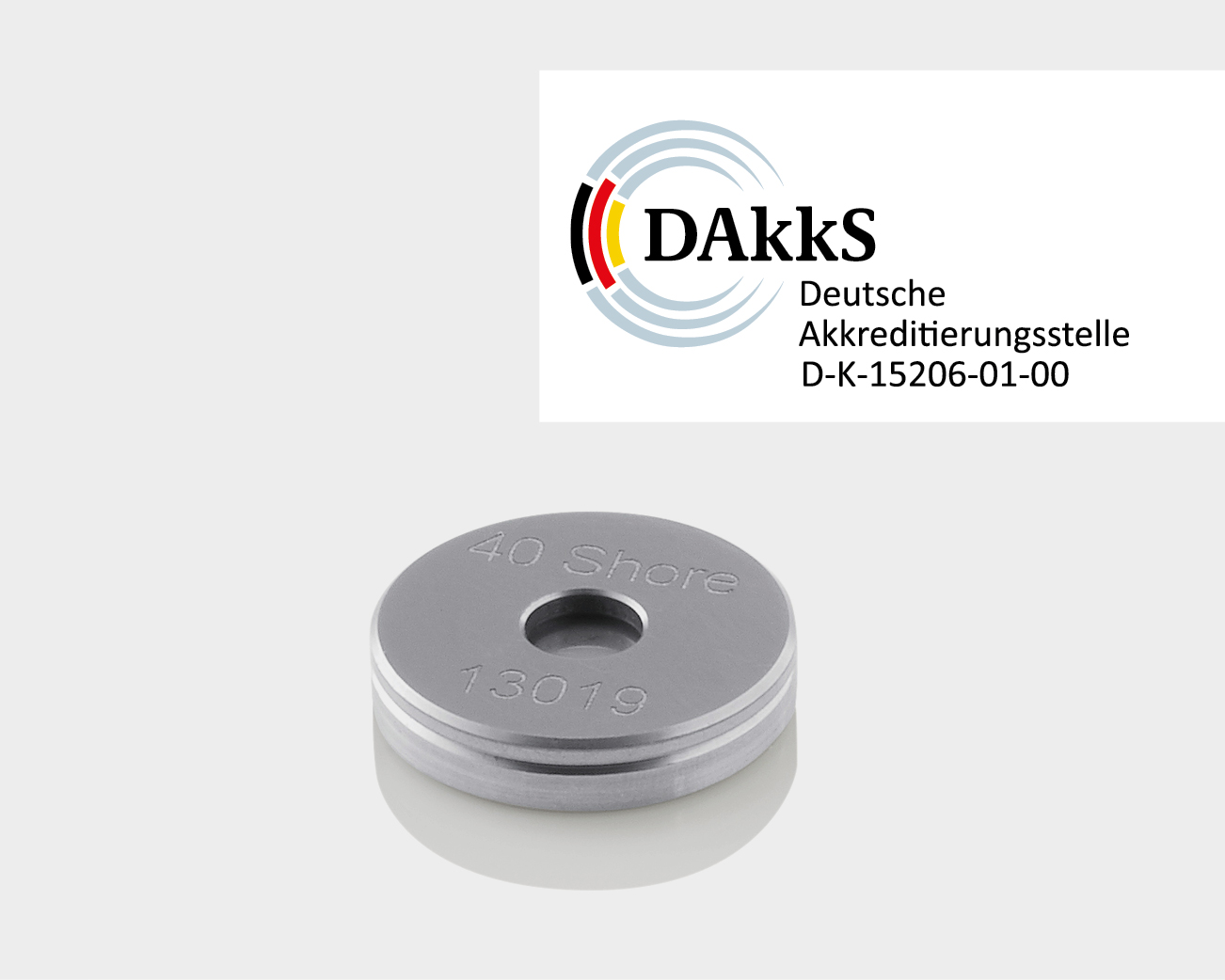

DAkkS accredited calibration certificate

Control rings

with DAkkS accredited calibration certificate

Standard blocks

with DAkkS accredited calibration certificate,

individual/3-piece or 6-piece set

Plate-shaped test specimens minimum 6 mm

1 Shore

Dim. W x H x D: min. 6,5 x 8,2 x 3,7 cm

max. 6,5 x 8,2 x 4,1 cm

Weight: 0,22 kg

Protection class: IP 30

None

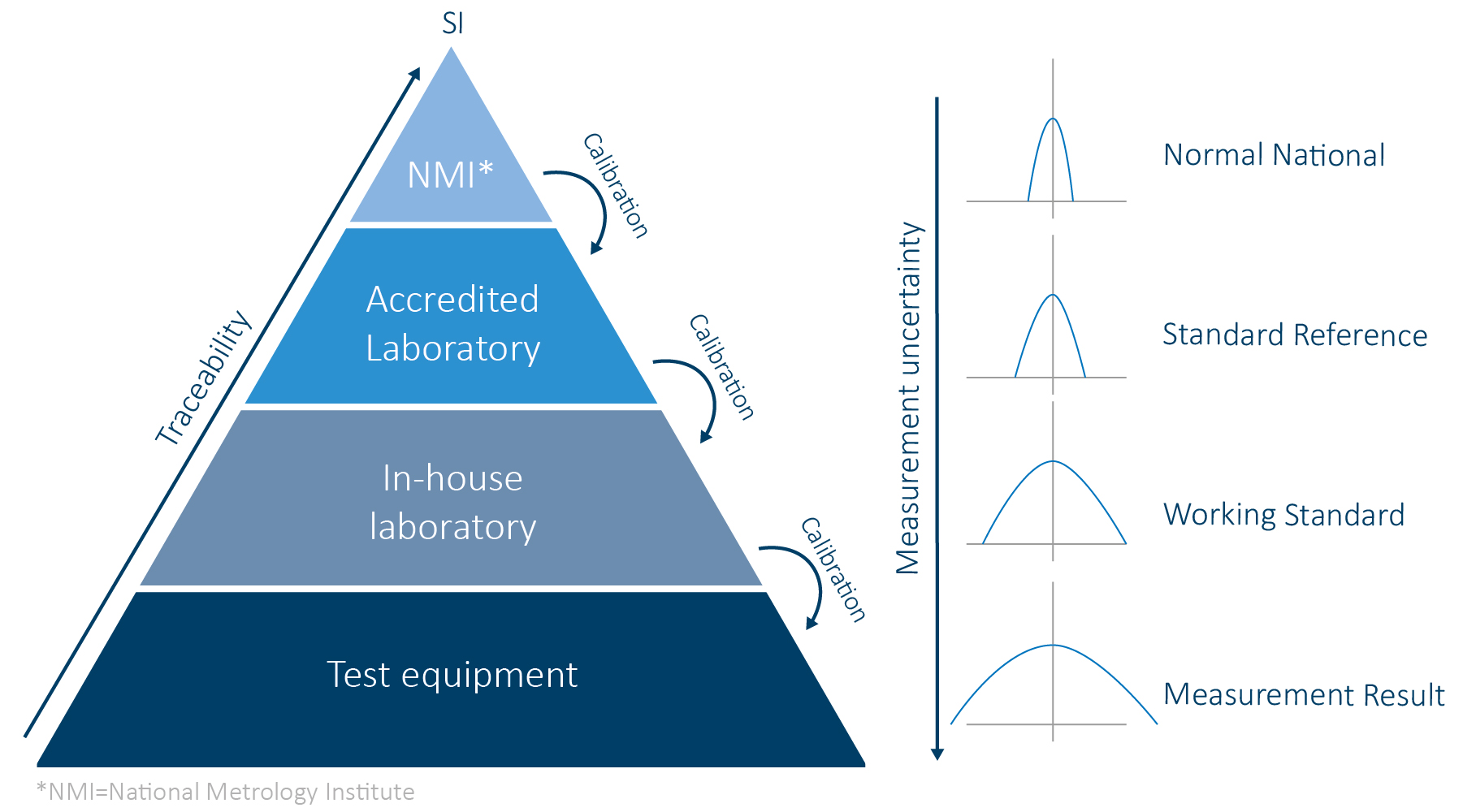

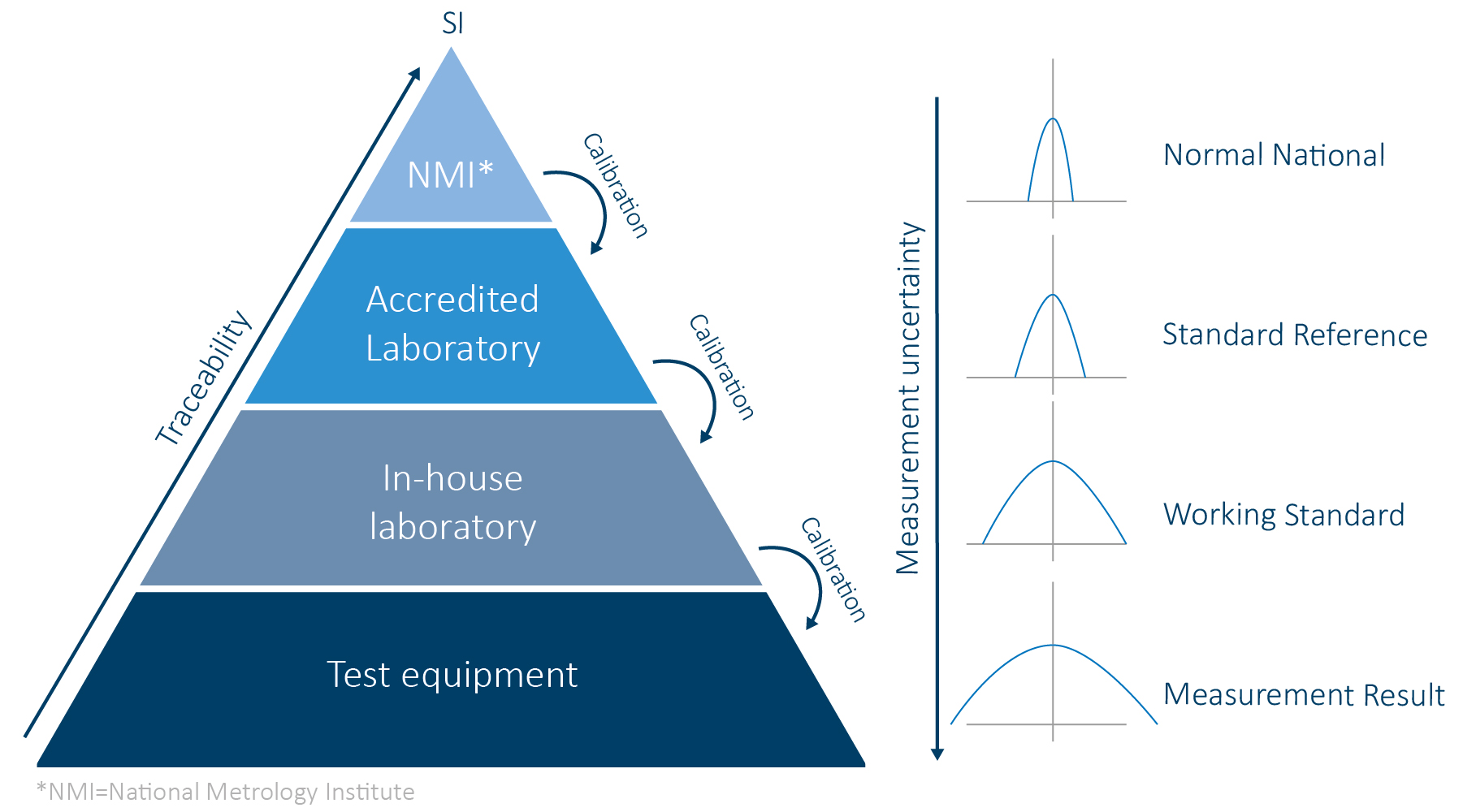

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

Analog handheld hardness tester for determining hardness according to Shore and Asker scales on flat specimens made of composite materials, flexible materials, elastomers. and polymers.

Plate-shaped test specimens minimum 6 mm

1 Shore

Dim. W x H x D: min. 6,5 x 8,2 x 3,7 cm

max. 6,5 x 8,2 x 4,1 cm

Weight: 0,22 kg

Protection class: IP 30

None

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email sales@bareiss.de

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

The HP is used for hardness determination according to Shore scale on flexible materials, elastomers, and plastics. For reliable hardness testing according to standard, a smooth and flat test specimen with a diameter of ≥ 35 mm and a material thickness of ≥ 6 mm is required. The handheld hardness tester is placed vertically on the surface of the test specimen and manually pressed. The specially designed, high-precision mechanics ensure minimal friction of the meter movement, thereby ensuring high measurement precision.

The determined hardness can be read on the analog display of the HP during the measurement. the precision of the hardness tester should be regularly verified by the user using standard blocks to ensure accurate measuring results.

Lightweight and compact

The compact size of the handheld hardness tester allows for convenient transport to the desired site of operation. Whether in the factory, warehouse, receipt of goods, or during quality inspections at the supplier, the HP is easy to carry and well protected by the practical carrying case.

Two measurements in one

With the optional maximum indicating pointer, the peak value of the hardness test is displayed on the dial even after the measurement.

Universally applicable

In addition to its use as a flexible and lightweight handheld hardness testing device, the HP, when expanded with a test stand, also offers a stationary solution that adapts to your requirements. When combined with our manual test stand BS 61 II, the HP also serves as a tabletop unit for measurements in a laboratory enviroment.

Other features

Carrying case

BS 61 II, manual test stand

Elasticity control unit

Shore A/Shore D

DAkkS accredited calibration certificate

Control rings

with DAkkS accredited calibration certificate

Standard blocks

with DAkkS accredited calibration certificate,

individual/3-piece or 6-piece set

We have experience.

We have been active in the field of measurement technology since 1954 - now in the third generation.

We stay true to ourselves.

All of our products are developed and manufactured in Germany.

We are accredited.

Our DAkkS accredited calibration laboratory is certified according to DIN EN/IEC 17025.

We are committed.

We are a member of the DIN committee and set standards there in the area of hardness.

We have inventive talent.

We have developed and registered over 25 patents in the last few decades.

We distribute worldwide.

We and our partners are there for you anywhere in the world.