- Product Overview

- Industry sectors

- Accredited service

- ISO 17025 calibration

- Manufacturer & calibration laboratory

- Rental device & contract measurement

- Seminars & training

- Support & infos

- Company

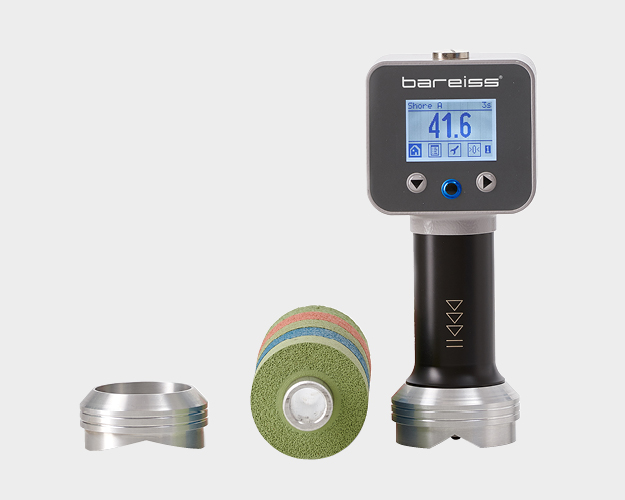

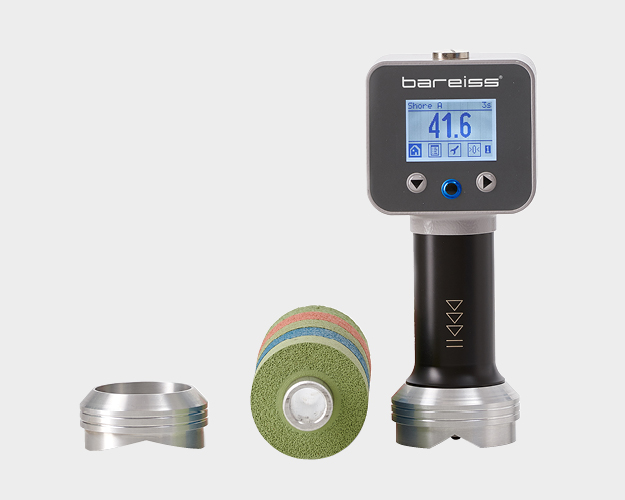

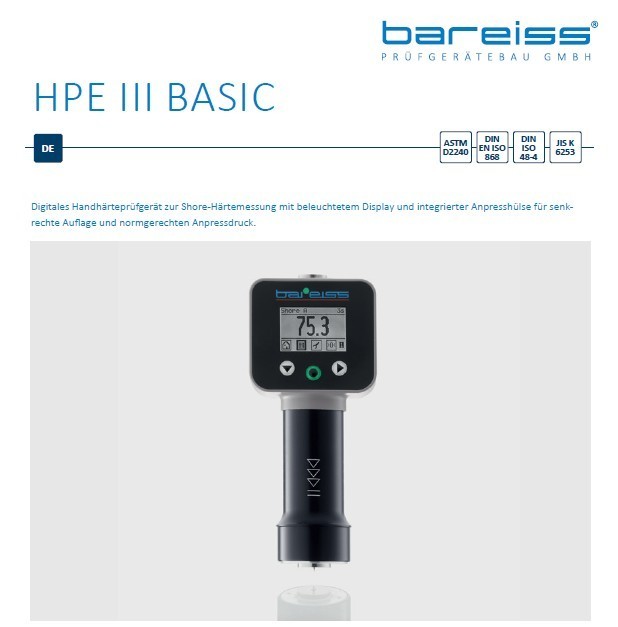

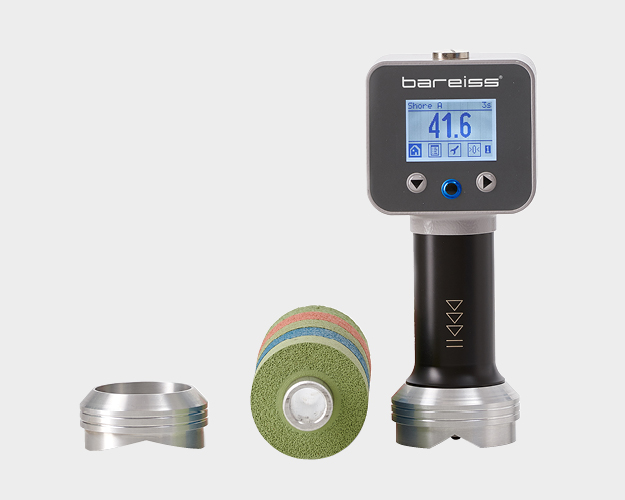

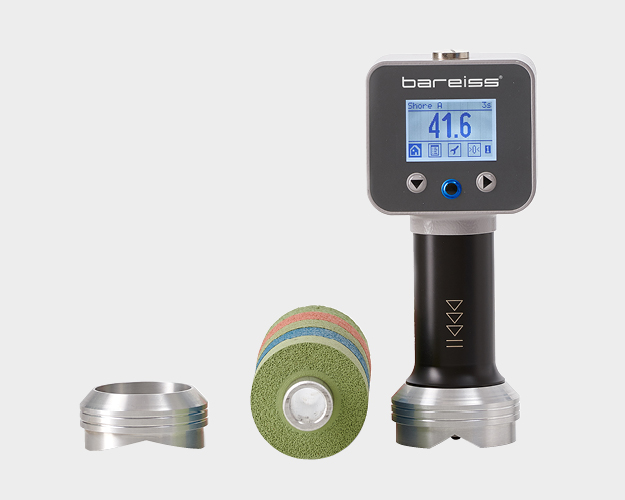

With the HPE III Basic handheld hardness tester, you can effortlessly measure the hardness of flexible materials, polymers, and composite materials. Its proven and sophisticated product desighn ensures correct measurement procedures and protects against operating errors. Thanks to the functional handle with integrated pressure sleeve, the hardness tester can be reliably operated and placed on the specimen with contact pressure conforming to standards. After the specified testing time has elapsed, it signals the user of successful measurement with a signal tone. All measurement data is then displayed on the illuminated display and can be conveniently exported via BareissOne software.

The HPE III Basic also measures humidity, ambient and sample temperature, as well as date and time as an additional feature.

Intuitive menu navigation

The simple menu navigation is operated via 3 buttons and is intuitively understandable after just a few steps. Changing the measurement time, viewing up to 300 measurement values, and many other functions are displayed to you in a few clicks.

Lithium-ion battery

USB data cable

Charging cable

Control ring 40 Shore A

Lightweight and compact

The compact size of the handheld hardness tester allows for comfortable transportation to the desired location. Whether in the factory, warehouse, receipt of goods, or during quality inspections at the supplier, the HPE III Basic is easy to carry and well protected by the practical transport case.

Reliable measurement values

The integrated spring system in the handle ensures that the HPE III Basic applies the force conforming to standard and the correct angle to the specimen. Operator influence is thus minimized, allowing you to focus on the important things.

Universally applicable

In addition to its use as a flexible and lightweight handheld hardness tester, the HPE III Basic offers a stationary solution with the extension of a test stand that adapts to your requirements. In combination with out manual test stand BS 61 or our automatic test stand BSA, the HPE III Basic also serves as a tabletop unit for measurements in a laboratory enviroment.

BareissOne – the software plattform for your measurement values

The unique and modular BareissOne software platform allows you to centrally store and evaluate all measurement values from your Bareiss test equipment. The user-friendly interface provides statistical analysis of measurement data with user management and automatic generation of test reports. Whether it's a standard test for individual measurements or a test series with complex text sequences, BareissOne meets your specific requirements.

Other features

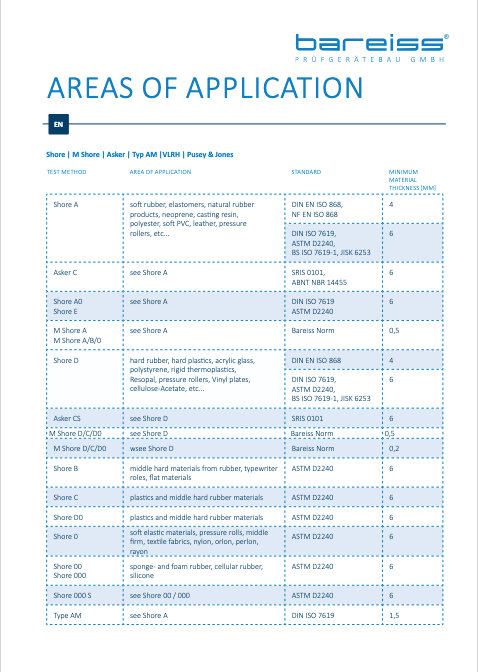

Hardness determination on composite materials, flexible materials, elastomers, plastics, foams, and automotive interiors.

The HPE III Basic handheld hardness tester is used for the determination of the hardness on composite materials, flexible materials, elsatomers, plastics, as well as foams and automotive interiors. For reliable hardness testing acording to standards, a smooth and flat test specimen with a diameter of ≥ 35 mm and a material thickness of ≥ 6 mm is required.

BSA II, automatic test stand

BS 61 II, manual test stand

Spring force control device

Shore A/Shore D

Prism 120°

Prism 150°

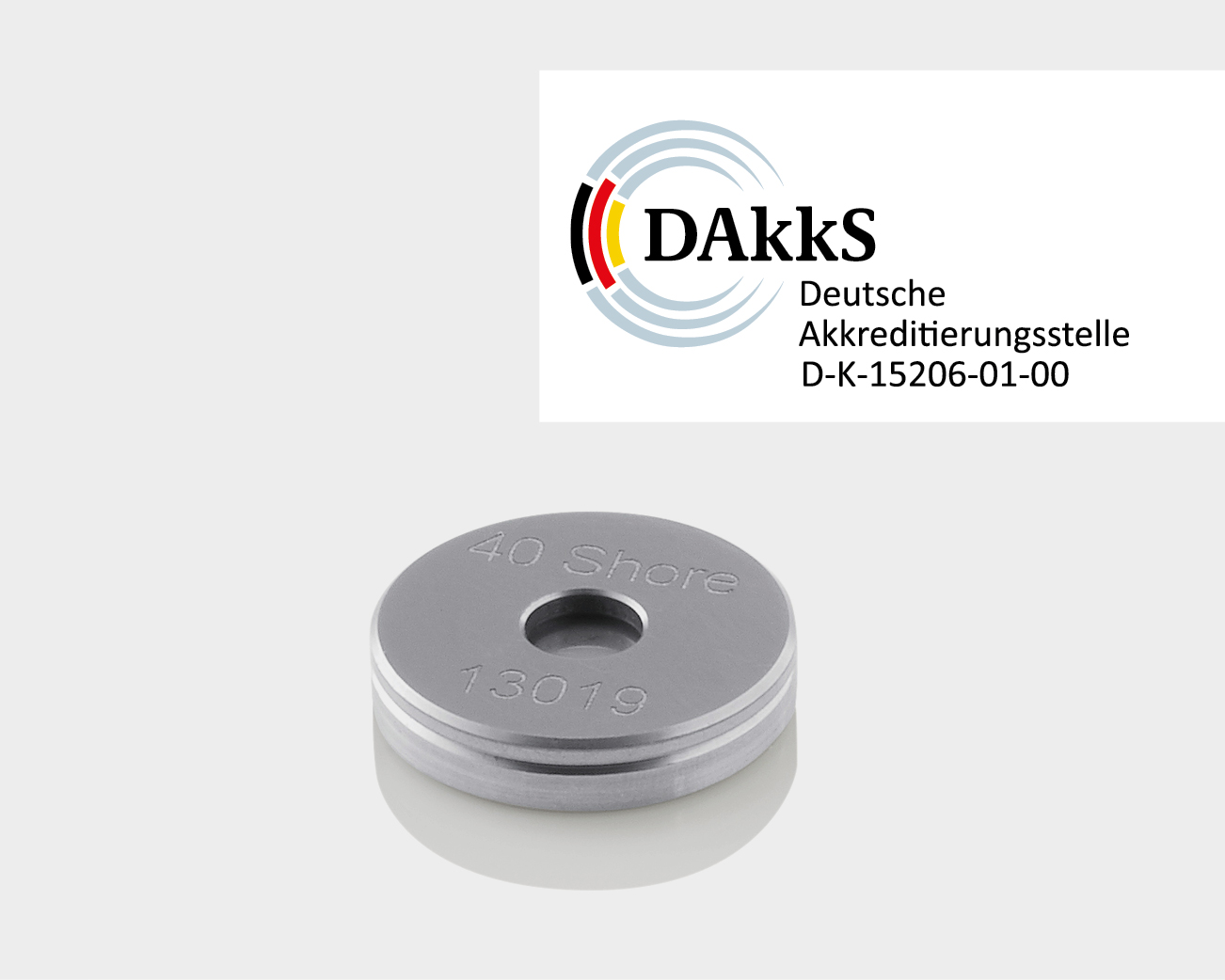

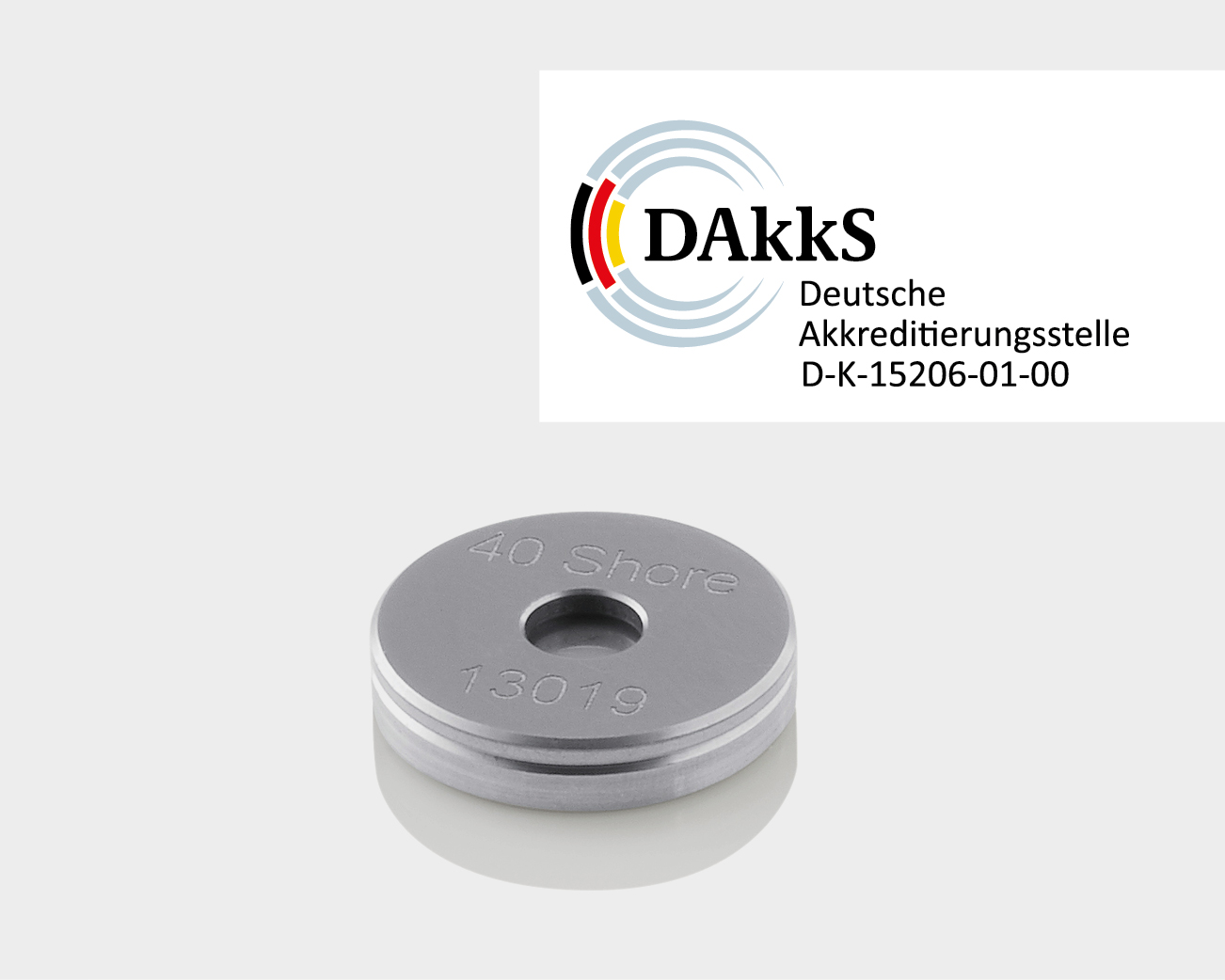

DAkkS accredited calibration certificate

Control rings

with DAkkS accredited calibration certificate

Standard blocks

with DAkkS accredited calibration certificate,

individually / sets of 3 or 6

Software

Plate-shaped test specimens minimum 6 mm

Cylindrical test specimens

0.1 Hardness units

Dim. W x H x D: 7 x 16 x 5,5 cm

Weight: 0,32 kg

Power supply: Lithium Ion Battery

Protection class: IP 50

Operating time: Up to 30 working hours

USB connection for data transfer, optional Bluetooth application possible

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

Digital handheld hardness tester for Shore hardness measurement with illuminated display, sensor for capturing ambient conditions, and integrated pressure sleeve for vertical support and contact pressure conforming to standards.

![]() Bareiss Silverline 25

Bareiss Silverline 25

New colors, lived responsibility – coatings for a better future

The transition to the new coating will begin mid-year. During the transition period, some devices may still be delivered with previous coating. We kindly ask for your understanding that the new coating cannot be guaranteed.

Plate-shaped test specimens minimum 6 mm

Cylindrical test specimens

0.1 Hardness units

Dim. W x H x D: 7 x 16 x 5,5 cm

Weight: 0,32 kg

Power supply: Lithium Ion Battery

Protection class: IP 50

Operating time: Up to 30 working hours

USB connection for data transfer, optional Bluetooth application possible

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email sales@bareiss.de

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

With the HPE III Basic handheld hardness tester, you can effortlessly measure the hardness of flexible materials, polymers, and composite materials. Its proven and sophisticated product desighn ensures correct measurement procedures and protects against operating errors. Thanks to the functional handle with integrated pressure sleeve, the hardness tester can be reliably operated and placed on the specimen with contact pressure conforming to standards. After the specified testing time has elapsed, it signals the user of successful measurement with a signal tone. All measurement data is then displayed on the illuminated display and can be conveniently exported via BareissOne software.

The HPE III Basic also measures humidity, ambient and sample temperature, as well as date and time as an additional feature.

Intuitive menu navigation

The simple menu navigation is operated via 3 buttons and is intuitively understandable after just a few steps. Changing the measurement time, viewing up to 300 measurement values, and many other functions are displayed to you in a few clicks.

Lightweight and compact

The compact size of the handheld hardness tester allows for comfortable transportation to the desired location. Whether in the factory, warehouse, receipt of goods, or during quality inspections at the supplier, the HPE III Basic is easy to carry and well protected by the practical transport case.

Reliable measurement values

The integrated spring system in the handle ensures that the HPE III Basic applies the force conforming to standard and the correct angle to the specimen. Operator influence is thus minimized, allowing you to focus on the important things.

Universally applicable

In addition to its use as a flexible and lightweight handheld hardness tester, the HPE III Basic offers a stationary solution with the extension of a test stand that adapts to your requirements. In combination with out manual test stand BS 61 or our automatic test stand BSA, the HPE III Basic also serves as a tabletop unit for measurements in a laboratory enviroment.

BareissOne – the software plattform for your measurement values

The unique and modular BareissOne software platform allows you to centrally store and evaluate all measurement values from your Bareiss test equipment. The user-friendly interface provides statistical analysis of measurement data with user management and automatic generation of test reports. Whether it's a standard test for individual measurements or a test series with complex text sequences, BareissOne meets your specific requirements.

Other features

Lithium-ion battery

USB data cable

Charging cable

Control ring 40 Shore A

BSA II, automatic test stand

BS 61 II, manual test stand

Spring force control device

Shore A/Shore D

Prism 120°

Prism 150°

DAkkS accredited calibration certificate

Control rings

with DAkkS accredited calibration certificate

Standard blocks

with DAkkS accredited calibration certificate,

individually / sets of 3 or 6

Software