- Product Overview

- Industry sectors

- Accredited service

- ISO 17025 calibration

- Manufacturer & calibration laboratory

- Rental device & contract measurement

- Seminars & training

- Support & infos

- Company

With the patented Kal-Rock, you can verify the depth measurement device of your Rockwell hardness tester. With a resolution of 0.0001 mm (0,1 µm), it controls the length measuring system of the hardness testers under a pre-load of max. 10 kg.

To calibrate, mount the calibration device on your instrument by inserting th Kal-Rock with its mounting bolt into the spindle hole. Replace the Rockwell indenter wth the Kal-Rock plunger. After setting the reference point, the actual calibration measurement starts. The Kal-Rock determines the actual measurement range and allows comparison with the measurement value determined by the instrument. The results of the test are displayed on the illuminated display of the connected electronic unit and are ready for export.

Other features

Kal-Rock measuring device

Elektronic unit

Adapter sleeve Ø 25 mm or Ø 22 mm

Plunger ball Ø 10 mm

USB cable

Instrument for calibrating the direction measurement of the depth of penetration of Rockwell hardness testing machines. Available with DAkkS accredited calibration certificate

DAkkS accredited calibration certificate

DGUV inspection

None

0.1 µm

Elektronic unit

Dim. W x H x D: min. 26 x 11,5 x 26,5 cm

max. 26 x 11,5 x 34 cm

Weight: 2,32 kg

Measuring device

Dim. W x H x D: 10 x 13,5 x 26,5 cm

Weight: 3,70 kg

Power supply: 100 - 240 VAC; 50/60 Hz

Protection class: IP 30

Fine adjustment of the length

Measuring device: ± 0,4 cm

Display accuracy

Measuring device: ± 0,2 µm

RS 232 and USB interface

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

Digital length-measuring device with electronic unit for calibrating the depth measuring device of Rockwell hardness testers.

None

0.1 µm

Elektronic unit

Dim. W x H x D: min. 26 x 11,5 x 26,5 cm

max. 26 x 11,5 x 34 cm

Weight: 2,32 kg

Measuring device

Dim. W x H x D: 10 x 13,5 x 26,5 cm

Weight: 3,70 kg

Power supply: 100 - 240 VAC; 50/60 Hz

Protection class: IP 30

Fine adjustment of the length

Measuring device: ± 0,4 cm

Display accuracy

Measuring device: ± 0,2 µm

RS 232 and USB interface

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email sales@bareiss.de

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

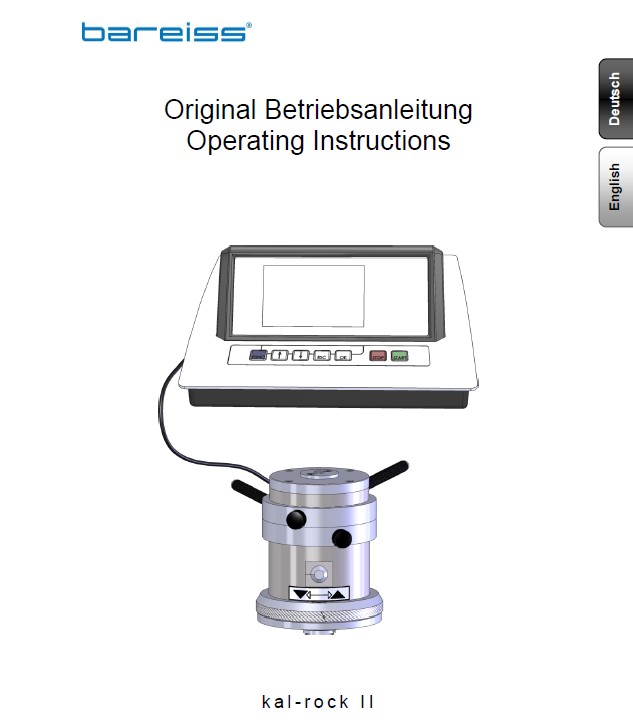

With the patented Kal-Rock, you can verify the depth measurement device of your Rockwell hardness tester. With a resolution of 0.0001 mm (0,1 µm), it controls the length measuring system of the hardness testers under a pre-load of max. 10 kg.

To calibrate, mount the calibration device on your instrument by inserting th Kal-Rock with its mounting bolt into the spindle hole. Replace the Rockwell indenter wth the Kal-Rock plunger. After setting the reference point, the actual calibration measurement starts. The Kal-Rock determines the actual measurement range and allows comparison with the measurement value determined by the instrument. The results of the test are displayed on the illuminated display of the connected electronic unit and are ready for export.

Other features

Kal-Rock measuring device

Elektronic unit

Adapter sleeve Ø 25 mm or Ø 22 mm

Plunger ball Ø 10 mm

USB cable

DAkkS accredited calibration certificate

DGUV inspection