- Product Overview

- Industry sectors

- Accredited service

- ISO 17025 calibration

- Manufacturer & calibration laboratory

- Rental device & contract measurement

- Seminars & training

- Support & infos

- Company

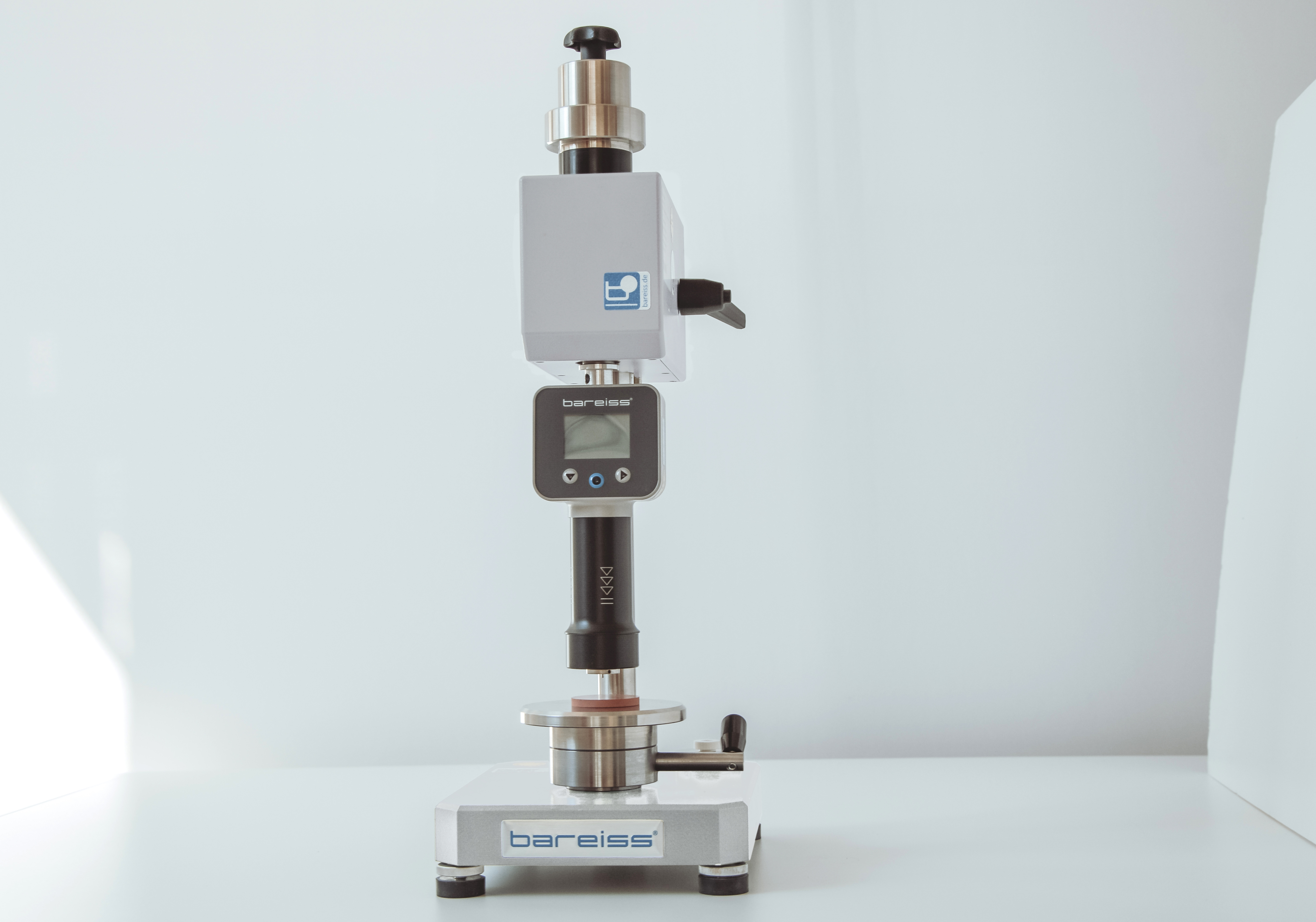

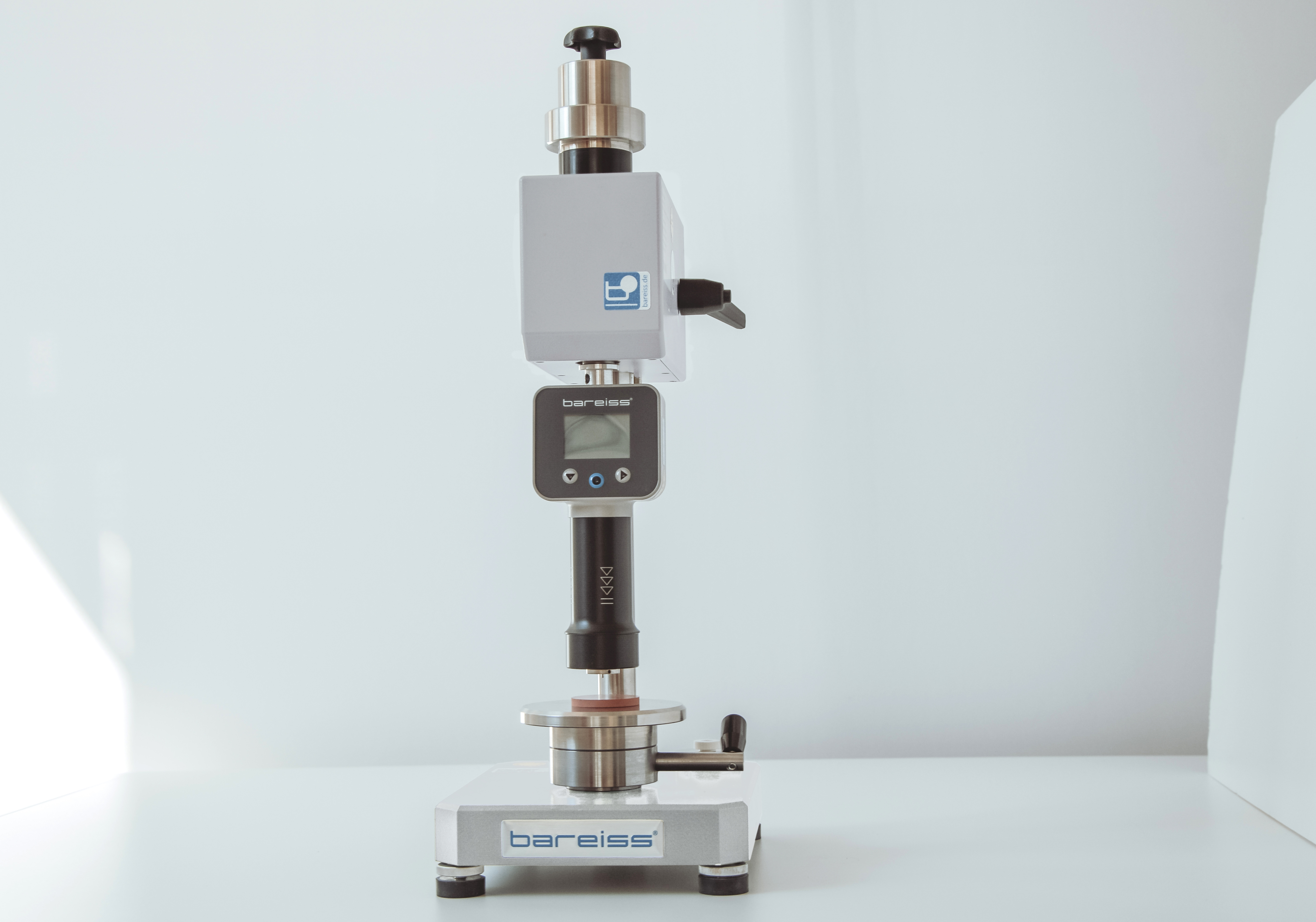

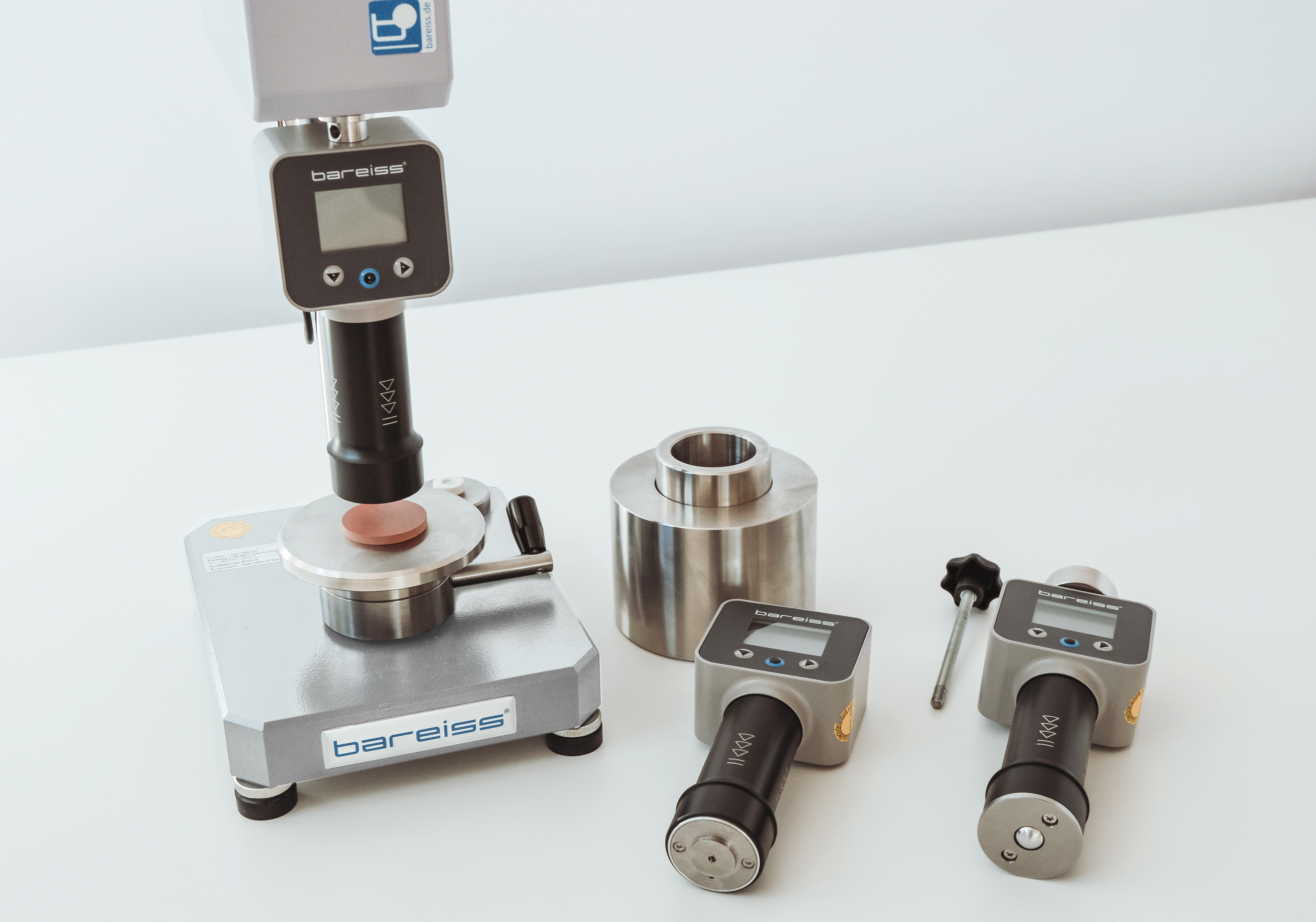

The automatic test stand BSA II expands the application area of your Bareiss handheld hardness tester from mobile use to stationary hardness tester in the laboratory. The BSA II automatically lowers the hardness tester onto the sample with a constant lowering speed conforming to standards and provides the normative contact pressure with its total mass. With the available additional weights for different measuring methods you can flexibly adjust it.

By using the test stand, you minimize potential user influences that may arise during manual measurement.

Expansion of the application area of your handheld hardness tester

With the automatic test stand BSA II, your hardness tester can be used not only mobile but also as a tabletop unit in the laboratory or in production.

Hardness testing conforming to standards

With the BSA II, you ensure that all normative requirements like constant lowering speed, defined contact pressure, and correct, perpendicular placement of the hardness tester for hardness testing are met.

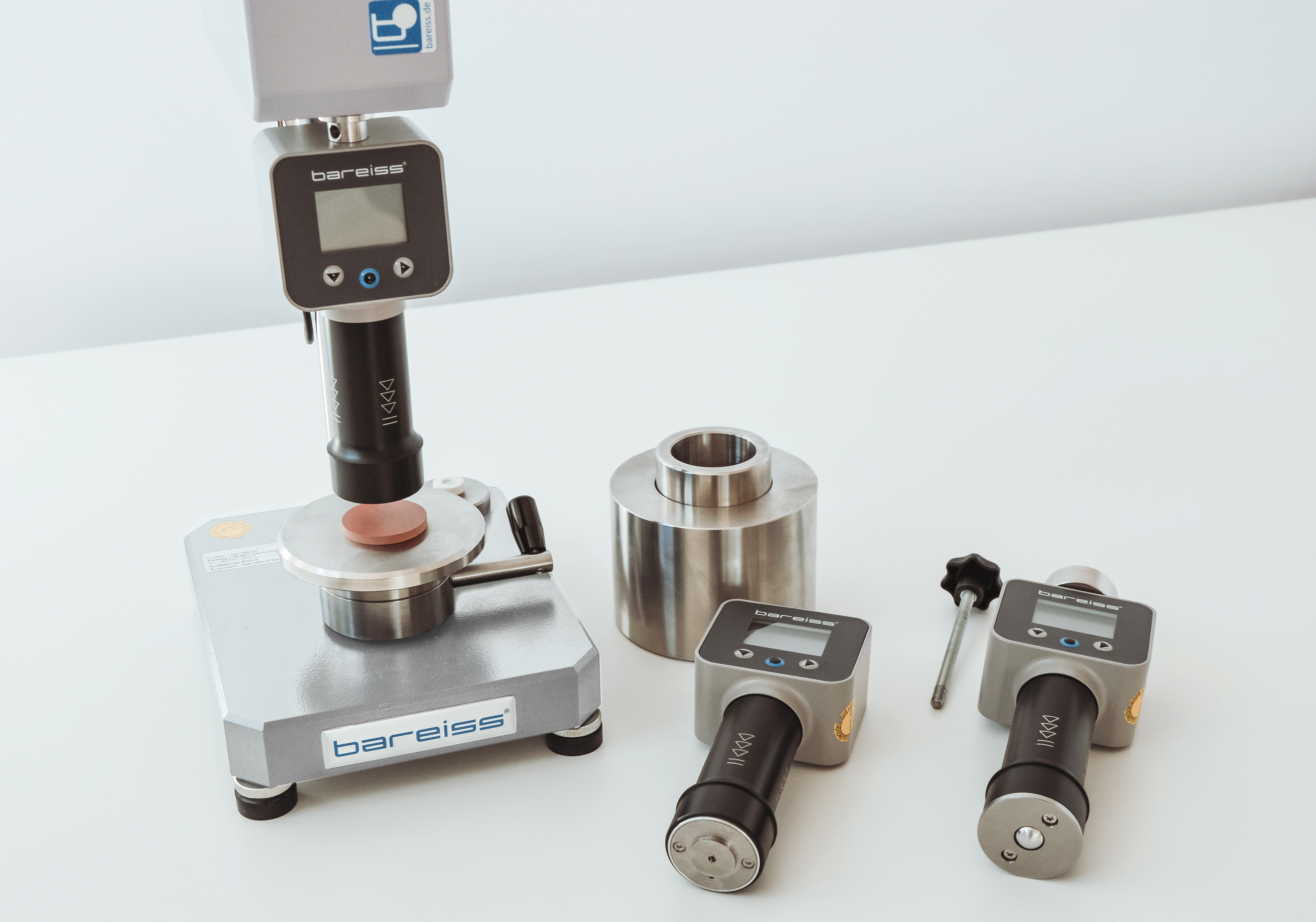

One test stand for all measuring methods

Through different additional weights and tightening rods, the BSA II is flexible for every measuring method of the HPE III Basic.

Other features

Plane-parallel samples of rubber, foams, and polymers

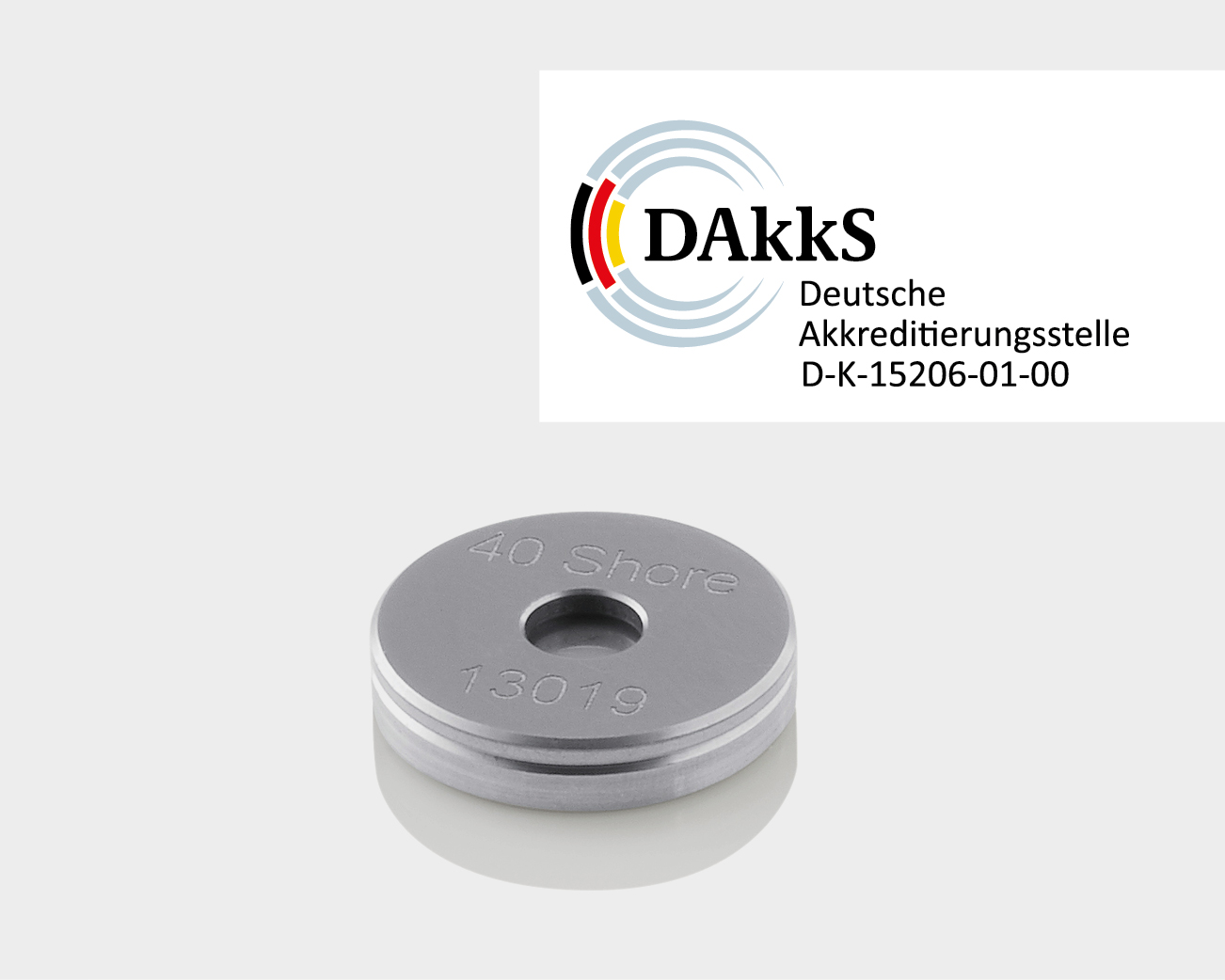

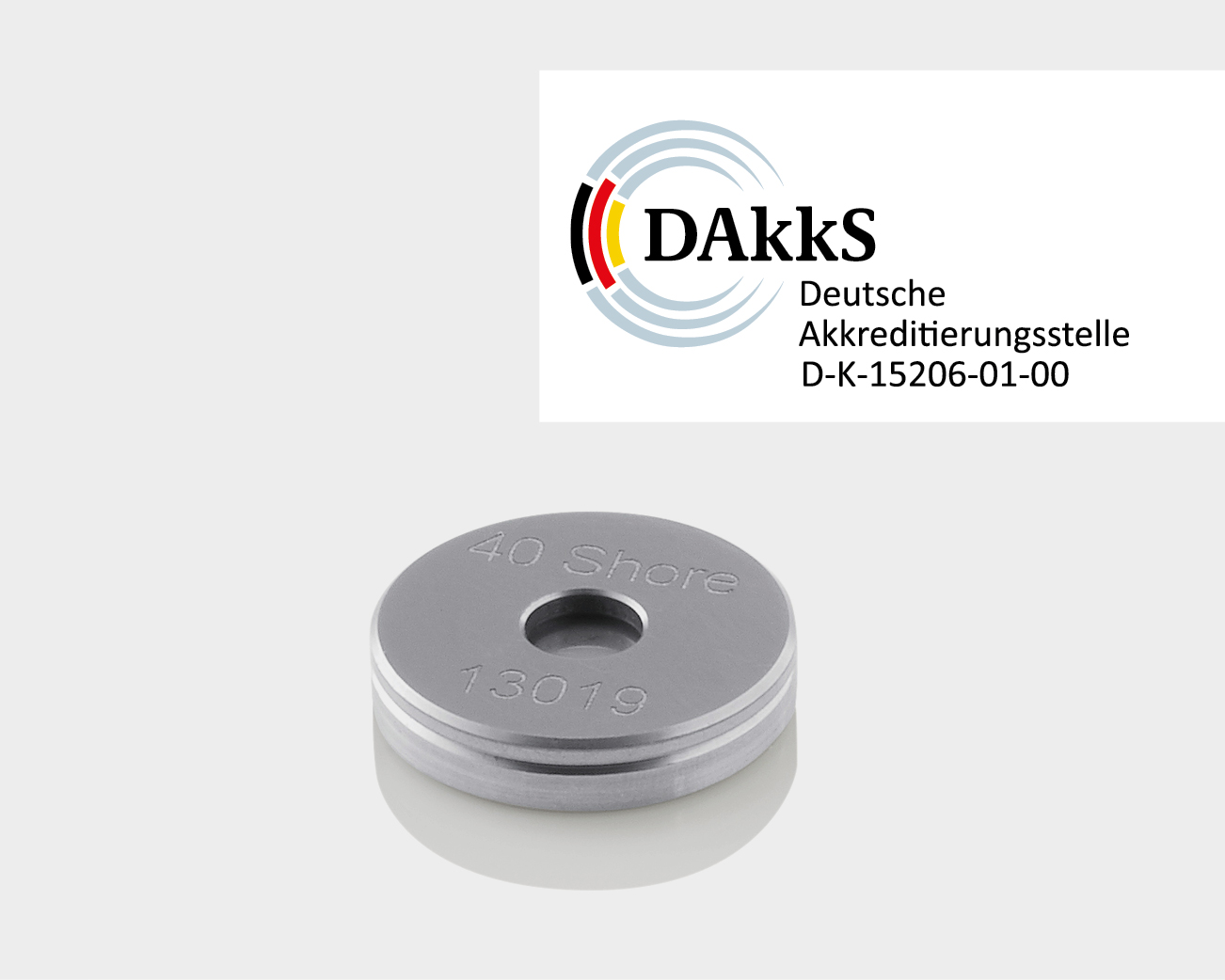

DAkkS accredited calibration certificate

Control rings

with DAkkS accredited calibration certificate

Additional weights and tightening rods for further measuring methods

Software

Plane-parallel samples with a minimum thickness of 6 mm.

BSA 400

Dim. W x H x D: 11,5 x 11,5 x 18 cm

Weight: 2,03 kg

BSA 1000

Dim. W x H x D: 11,5 x 19 x 18 cm

Weight: 2,70 kg

BSA 5000

Dim. W x H x D: 11,5 x 23 x 18 cm

Weight: 6,75 kg

Test stand BSA 400

Dim. W x H x D: min. 16 x 45 x 18 cm

max. 16 x 48 x 23 cm

Test stand BSA 1000

Dim. W x H x D: min. 11,5 x 45 x 18 cm

max. 11,5 x 55 x 23 cm

Test stand BSA 5000

Dim. W x H x D: min. 11,5 x 45 x 18 cm

max. 11,5 x 59 x 23 cm

Weight test stand: 4,98 kg

Power supply: 100-200 VAC; 50/60 Hz

Protection class: IP 20

The device can be connected to the computer via a special USB cable included in the scope of delivery.

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any qestions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

Automatic test stand for handheld hardness testers. With the BSA II, you ensure that your measurements with the handheld hardness tester are carried out with standard lowering speed, contact pressure, and at right angles with the material.

![]() Bareiss Silverline 25

Bareiss Silverline 25

New colors, lived responsibility – coatings for a better future

The transition to the new coating will begin mid-year. During the transition period, some devices may still be delivered with previous coating. We kindly ask for your understanding that the new coating cannot be guaranteed.

Plane-parallel samples with a minimum thickness of 6 mm.

BSA 400

Dim. W x H x D: 11,5 x 11,5 x 18 cm

Weight: 2,03 kg

BSA 1000

Dim. W x H x D: 11,5 x 19 x 18 cm

Weight: 2,70 kg

BSA 5000

Dim. W x H x D: 11,5 x 23 x 18 cm

Weight: 6,75 kg

Test stand BSA 400

Dim. W x H x D: min. 16 x 45 x 18 cm

max. 16 x 48 x 23 cm

Test stand BSA 1000

Dim. W x H x D: min. 11,5 x 45 x 18 cm

max. 11,5 x 55 x 23 cm

Test stand BSA 5000

Dim. W x H x D: min. 11,5 x 45 x 18 cm

max. 11,5 x 59 x 23 cm

Weight test stand: 4,98 kg

Power supply: 100-200 VAC; 50/60 Hz

Protection class: IP 20

The device can be connected to the computer via a special USB cable included in the scope of delivery.

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any qestions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email sales@bareiss.de

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

The automatic test stand BSA II expands the application area of your Bareiss handheld hardness tester from mobile use to stationary hardness tester in the laboratory. The BSA II automatically lowers the hardness tester onto the sample with a constant lowering speed conforming to standards and provides the normative contact pressure with its total mass. With the available additional weights for different measuring methods you can flexibly adjust it.

By using the test stand, you minimize potential user influences that may arise during manual measurement.

Expansion of the application area of your handheld hardness tester

With the automatic test stand BSA II, your hardness tester can be used not only mobile but also as a tabletop unit in the laboratory or in production.

Hardness testing conforming to standards

With the BSA II, you ensure that all normative requirements like constant lowering speed, defined contact pressure, and correct, perpendicular placement of the hardness tester for hardness testing are met.

One test stand for all measuring methods

Through different additional weights and tightening rods, the BSA II is flexible for every measuring method of the HPE III Basic.

Other features

DAkkS accredited calibration certificate

Control rings

with DAkkS accredited calibration certificate

Additional weights and tightening rods for further measuring methods

Software