- Product Overview

- Industry sectors

- Accredited service

- ISO 17025 calibration

- Manufacturer & calibration laboratory

- Rental device & contract measurement

- Seminars & training

- Support & infos

- Company

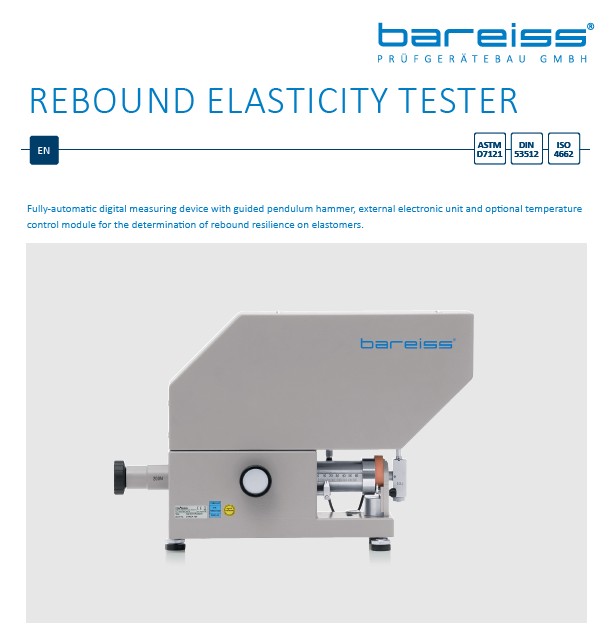

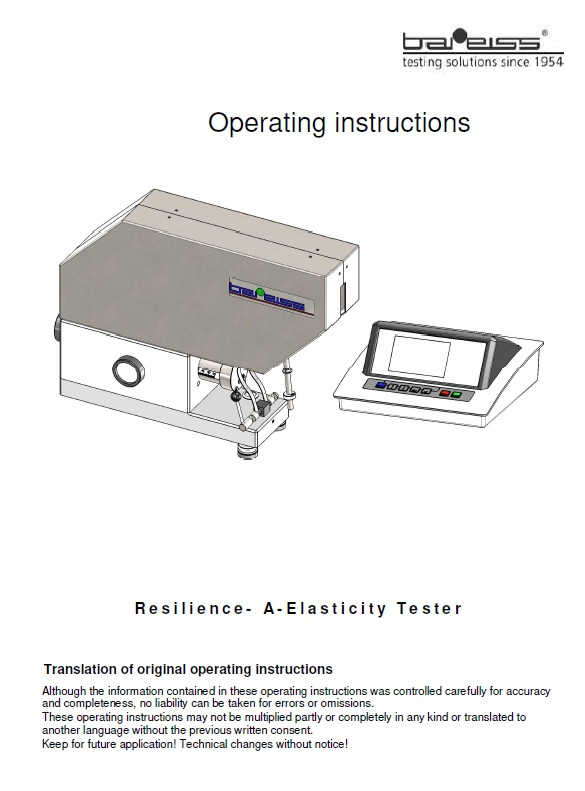

The Rebound Resilience Tester automatically determines the resilience of elastomers and similar materials for you. The integrated spring terminal system can be adjusted to different sample thicknesses and securely and easily fixes the test specimens for testing. After pressing the start button, the measuring process is carried out fully automatically.

Thanks to the optional heating module, it also allows measurements on heated test specimens, providing information on the change in the resilience behavior of the materials under temperature influence.

Different measurement modes

In addition to measurements according to standard, it is possible to perform customized measurements. The major advantage is that the measurement results of the preconditioning are also displayed and can be considered for evalutation.

Testing device with pendulum hammer

Anvil plate with spring terminal system

Elektronic unit

Easy and intuitive operation

With the simple clamping fixture with integrated scale, you can position your samples easily and intuitively. After a few simple steps, you can start the measurement.

Measurement under temperature influence with optional heating module

Other features

Mehtod for determining the behavior of the resilience of elastomers.

DAkkS accredited calibration certificate

Anvil plate

Heating module up to 100°C

Clamping unit 200 N

Pendulum hammer R 40 mm

Pendulum hammer R 15 mm

Software

Sample thickness 12-60 mm

Diameter 29-53 mm

0.1 % Rebound elasticity

Rebound mechanical

Dim. W x H x D: min. 30 x 38,5 x 45,5 cm

max. 30 x 38,5 x 63,5 cm

Weight: 48,00 kg

Rebound-Automat

Dim. W x H x D: min. 30 x 40 x 51 cm

max. 30 x 40 x 64 cm

Weight: 55,00 kg

Elektronic unit

Dim. W x H x D: min. 26 x 11,5 x 26,5 cm

max. 26 x 11,5 x 34 cm

Weight: 2,32 kg

Power supply: 100 - 240 VAC; 50/60 Hz

Protection class: IP 30

Pendulum

Length: 200 mm

Angle of fall: 90 Grad

Impact velocity: 2 m/s

USB or RS 232 interfaces for data transfer (Software required)

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

Fully automated testing device for determining the rebound resilience of elastomers.

Sample thickness 12-60 mm

Diameter 29-53 mm

0.1 % Rebound elasticity

Rebound mechanical

Dim. W x H x D: min. 30 x 38,5 x 45,5 cm

max. 30 x 38,5 x 63,5 cm

Weight: 48,00 kg

Rebound-Automat

Dim. W x H x D: min. 30 x 40 x 51 cm

max. 30 x 40 x 64 cm

Weight: 55,00 kg

Elektronic unit

Dim. W x H x D: min. 26 x 11,5 x 26,5 cm

max. 26 x 11,5 x 34 cm

Weight: 2,32 kg

Power supply: 100 - 240 VAC; 50/60 Hz

Protection class: IP 30

Pendulum

Length: 200 mm

Angle of fall: 90 Grad

Impact velocity: 2 m/s

USB or RS 232 interfaces for data transfer (Software required)

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

DAkkS-accredited laboratory since 1996 – Calibrations meeting the highest requirements and global standards.

Calibration reminders – We automatically remind you of your next calibration.

Service packages – Accredited calibration including maintenance and repair at a fixed price. Everything from a single source.

Trust Bareiss for reliable calibrations and accurate measurement results.

Benefit from our experience as a manufacturer and accredited calibration laboratory.

Bareiss recommendation: Laboratory conditions according to DIN ISO 23529

We are happy to answer any questions you might have about hardness testing!

Phone +49 7305 9642-0

Fax +49 7305 9642-22

Email sales@bareiss.de

Opening hours:

Monday - Thursday: 07:00 - 16:00

Friday: 07:00 - 12:00

The Rebound Resilience Tester automatically determines the resilience of elastomers and similar materials for you. The integrated spring terminal system can be adjusted to different sample thicknesses and securely and easily fixes the test specimens for testing. After pressing the start button, the measuring process is carried out fully automatically.

Thanks to the optional heating module, it also allows measurements on heated test specimens, providing information on the change in the resilience behavior of the materials under temperature influence.

Different measurement modes

In addition to measurements according to standard, it is possible to perform customized measurements. The major advantage is that the measurement results of the preconditioning are also displayed and can be considered for evalutation.

Easy and intuitive operation

With the simple clamping fixture with integrated scale, you can position your samples easily and intuitively. After a few simple steps, you can start the measurement.

Measurement under temperature influence with optional heating module

Other features

Testing device with pendulum hammer

Anvil plate with spring terminal system

Elektronic unit

DAkkS accredited calibration certificate

Anvil plate

Heating module up to 100°C

Clamping unit 200 N

Pendulum hammer R 40 mm

Pendulum hammer R 15 mm

Software